Monitoring Cure Characteristics of a Thermoset Epoxy by ATR/FT-IR

Some ATR / FTIR applications require a high performance, robust, and versatile accessory to accommodate difficult materials or high temperatures. As an example, the curing of a thermoset epoxy is evaluated and results are discussed.

Some ATR / FTIR applications require a high performance, robust, and versatile accessory to accommodate difficult materials or high temperatures. As an example, the curing of a thermoset epoxy is evaluated and results are discussed.

Attenuated total reflection (ATR) has become a primary FTIR sampling technique because of its versatility and ease of use, often entailing no sample preparation. Some materials and applications, however, require an especially robust ATR accessory. Examples include

- Rigid polymers and plastics

- Coated metals and wires

- High temperature thermoset resins

- Monitoring high temperature surface reactions

Instrumentation

The PIKE Technologies GladiATR (Figure 1) equipped with a resistively heated plate was used in this investigation. Operational temperature of the heated plate is from ambient to 210 °C.

Figure 1

Its monolithic diamond, a scratch and fracture resistant crystal, provides a platform to withstand applied pressures of greater than 30,000 psi. This attribute is imperative to assure intimate crystal-sample contact of mechanically rigid samples, achieving the highest quality spectra. In addition, the GladiATR utilizes optimized reflective optics for maximum energy throughput, which maximizes signal to noise ratio. This, in turn, allows for higher precision for low absorbing or low concentration components within a sample.

Measurement Parameters

All spectra were collected at 8 cm–1 spectral resolution co-averaging 5 scans. The two-part thermoset epoxy investigated is suitable for applications such as bonding metal, glasses, and ceramics. Epoxy components A and B were mixed per the manufacturer's specifications at room temperature, and applied directly onto the GladiATR crystal equilibrated at a prescribed temperature (80, 90, 100, 120 °C). Curing characteristics were monitored via FTIR spectra as a function of time and temperature. Once the reaction came to completion, the residual was aggressively scraped off using a scalpel without harm to the monolithic diamond due to the diamond crystal's extreme durability.

Application Results

ATR is an optimal FTIR accessory for evaluating cure characteristics of adhesives. These data are useful for formulation development as well as for quality control. Comparing spectra as a function of time may be used to determine reaction kinetics by evaluating absorbance band depletion and evolution as the reaction proceeds. This method also may be used to evaluate cure time by determining the time required to reach steady-state conditions.

Figure 2

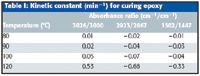

Figure 2 shows spectra collected using the GladiATR accessory. By plotting the ratio of selected absorbance bands as a function of time, reaction kinetics may be evaluated (Figure 3). At each temperature step, a brief lag period was observed followed by a decrease or increase in the value of the band ratio and eventually achieving steady-state conditions. Assuming a linear fit during the reaction phase, a kinetic constant was determined (Table I). These data exhibited an exponential increase or decay with increasing temperatures.

Figure 3

Summary

A high temperature epoxy curing study is presented as an example application where a high performance, robust ATR accessory is desirable. Through FTIR data, reaction kinetics were determined. PIKE Technologies' GladiATR provides exceptional quality data for demanding and high temperature applications.

Table I: Kinetic constant (minâ1) for curing epoxy

PIKE Technologies

6125 Cottonwood Drive, Madison, WI 53719

Tel. (608) 274-2721, Fax (608) 274-0103