Analysis of Iodine Value in Pork Fat Using FT–NIR

Pork fat was directly analyzed in this study with Bruker's FT-NIR system for iodine value (IV) with an accuracy expressed in RMSEP of 1.1 IV.

Hui Li, Robert Cocciarrdi and John Richmond, Bruker Optics, Inc.

Pork fat was directly analyzed in this study with Bruker's FT-NIR system for iodine value (IV) with an accuracy expressed in RMSEP of 1.1 IV.

Dietary intake of pigs plays a major role in determining the composition of pork fat, which is a major component of processed pork meat products. Dried distiller's grains with solubles (DDGS) is a by-product of fuel ethanol industry and it has fat content that is high in unsaturated fatty acids. Recently, the increased uptaking of DDGS by pigs has resulted in pork fat with higher levels of unsaturated fatty acids, which is undesirable because it causes the pork fat to become much softer, which makes it more difficult to slice during meat processing. It also reduces the quality of pork meat products since it decreases the firmness of pork loin and increases the rate of oxidation of pork fat, reducing the shelf life of these products. Therefore, pork meat processors need a method to monitor the pork fat firmness. One way to monitor pork fat firmness is to measure IV, which is directly related to the amount of unsaturated fatty acids in pork fat. Conventional methods such as the Wijs or GC-MS are time consuming and require solvents and reagents. Fourier transform–near infrared (FT-NIR) has been used to measure IV in edible oils and extracted fats (1). In this study, pork fat samples were place in petri dish and scanned directly through the bottom of the dish in diffuse reflectance using a Bruker Tango FT-NIR spectrometer. High quality NIR spectra of pork fat can be obtained on-site in under a minute (Figure 1), which can give meat processors a quick feedback about the pork fat firmness.

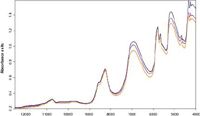

Figure 1: NIR spectra of pork fat samples (blue 84 IV, magenta 74 IV, and orange 63 IV), measured in diffuse reflectance.

Experimental Conditions

Pork fat samples were cut into large pieces and placed on a glass petri dish located directly above the quartz window of the integrating sphere channel of the Tango. Samples were scanned across the NIR spectral range (12,500 to 4000 cm-1) and for each measurement 32 scans were collected at a resolution of 8 cm-1. Over 300 samples of pork fat obtained from the belly and jowl of pigs fed with diets containing DDGS and other feeds were used to develop a calibration with iodine values ranging from 60.4 to 87.4. The calibration was developed using PLS regression by correlating FT-NIR spectra of pork fat samples to their respective GC-MS reference data using the OPUS/QUANT2 software package.

Results

The PLS calibration was optimized using a leave-one-out cross validation and by using the unique optimization routine in OPUS/QUANT2 which can help the end user to select regions, data preprocessing methods, and rank that gives the best PLS model. The PLS calibration model ultimately selected generated a R2 value of 95.5 and root mean square error of cross validation (RMSECV) of 1.1 IV. The model was then validated with a set of independent samples using the test set validation option in OPUS/QUANT2 and similar results compared to the cross validation was obtained with a R2 value of 95.2 and a root mean square error of prediction (RMSEP) of 1.1 IV.

Conclusions

This method can be used by meat processing plants and pork producers to provide a rapid feedback on pork fat quality for adjusting pig dietary intake in order for pork producers to deliver meat of desirable quality.

Reference

(1) American Oil Chemist Society standard procedure Cd 1e-01.

Bruker Optics, Inc.

19 Fortune Drive, Billerica, MA 01821

tel. (978) 439-9899, Fax: (978) 663-9177

Website: www.brukeroptics.com

Thermo Fisher Scientists Highlight the Latest Advances in Process Monitoring with Raman Spectroscopy

April 1st 2025In this exclusive Spectroscopy interview, John Richmond and Tom Dearing of Thermo Fisher Scientific discuss the company’s Raman technology and the latest trends for process monitoring across various applications.

A Seamless Trace Elemental Analysis Prescription for Quality Pharmaceuticals

March 31st 2025Quality assurance and quality control (QA/QC) are essential in pharmaceutical manufacturing to ensure compliance with standards like United States Pharmacopoeia <232> and ICH Q3D, as well as FDA regulations. Reliable and user-friendly testing solutions help QA/QC labs deliver precise trace elemental analyses while meeting throughput demands and data security requirements.