Revisiting IR Transmission Sampling of Polymers

Infrared (IR) sampling techniques of attenuated total reflectance (ATR) and transmission for polymer analysis are compared and contrasted. Using a real-world application, IR analysis of silane-grafted linear low density polyethylene (LLDPE) pellets is presented to illustrate the benefit of IR film transmission sampling.

Jenni L. Briggs, PIKE Technologies

Infrared (IR) sampling techniques of attenuated total reflectance (ATR) and transmission for polymer analysis are compared and contrasted. Using a real-world application, IR analysis of silane-grafted linear low density polyethylene (LLDPE) pellets is presented to illustrate the benefit of IR film transmission sampling.

For infrared analysis of polymers, ATR has displaced transmission sampling in many industrial applications. The primary reason is simplicity; ATR requires no sample preparation. Given the evolution of polymer sampling techniques in practice, one might question whether IR transmission of polymer films has gone the way of the KBr pellet, another "old school" technique. In many cases it has, justifiably. However, there are applications where transmission of polymer films remains a primary IR sampling technique. Examples include the investigation of polymer additives and analysis of small concentration components.

To illustrate this point, a real-world application is presented. In this case study, a polymer company is using IR spectroscopy to monitor the quality and chemical structure of silane-grafted LLDPE, a polymer used in electrical wire coatings, manufactured from a start-up production line.

Experimental Conditions

The IR spectra of silane-grafted LLDPE from two production lines were collected using transmission and ATR. Films were made using the PIKE Heated Platens Accessory (Figure 1) and the Auto-CrushIR hydraulic press. The spacers for the Heated Platens Accessory range from 15 to 500 microns. For this study, it was determined 100 micron thick films were optimal based on the spectral signature of the polymer. To create the film, 15 mg of polymer sample was placed on the heated platen held at 160 °C. The accessory was placed into the hydraulic press where it was held for 90 s under 2 tons of force. The heated platens were cooled to 50 °C using the cooling chamber prior to removing the polymer film from the platen. ATR spectra were collected using the PIKE GladiATR single reflection diamond ATR. ATR correction was performed.

Figure 1: PIKE heated platens accessory.

Results

The CH-stretching, -bending, and -rocking vibrations from LLDPE are easily identified from a spectrum collected using ATR sampling, because these absorbance bands are inherently strong. However, spectral bands resulting from the grafting reaction are more difficult to discern. IR transmission analysis offers an alternative sampling method, allowing band strength optimization by easily making films of various thicknesses using heated platens and a hydraulic press.

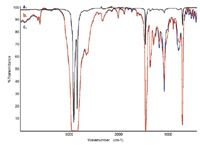

Figure 2 shows the IR spectra of silane-grafted LLDPE samples, the target formulation and the formulation from the start-up production line. By analyzing thin films by transmission the chemical structure of Si—OCH3 is easily identified at 1192 cm-1. Shieh and Tsai (1) found a linear relationship between the degree of grafting and the ratio of the 1192 cm-1 absorbance band to the absorbance band caused by CH3 bending vibration of the polyethylene base located at 1378 cm-1 (1). For this application where formula matching is the objective, IR film analysis allows for the comparisons of weak spectral bands found in the fingerprint region more effectively than comparing ATR spectra.

Figure 2: Spectra of target formulation collected via ATR (a), target formulation via transmission (c), and production formulation via transmission (b) of silane-grafted LLDPE.

Conclusion

IR transmission analysis remains a viable technique for the evaluation of additives and other small concentration components in polymers. Films are easily made by using heated platens and a hydraulic press.

Reference

(1) Y. Shieh and T. Tsai, J. Appl. Polymer Sci. 69, 255–261 (1998).

PIKE Technologies

6125 Cottonwood Drive, Madison, WI 53719

tel. (608) 274-2721

Website: www.PIKETech.com

Thermo Fisher Scientists Highlight the Latest Advances in Process Monitoring with Raman Spectroscopy

April 1st 2025In this exclusive Spectroscopy interview, John Richmond and Tom Dearing of Thermo Fisher Scientific discuss the company’s Raman technology and the latest trends for process monitoring across various applications.

A Seamless Trace Elemental Analysis Prescription for Quality Pharmaceuticals

March 31st 2025Quality assurance and quality control (QA/QC) are essential in pharmaceutical manufacturing to ensure compliance with standards like United States Pharmacopoeia <232> and ICH Q3D, as well as FDA regulations. Reliable and user-friendly testing solutions help QA/QC labs deliver precise trace elemental analyses while meeting throughput demands and data security requirements.