Is Your Spectrophotometer Still “Pharma Compliant”? A Review of the Latest USP Chapter

Spectroscopy

The U.S. and European Pharmacopeia chapters covering ultraviolet and visible spectroscopy have recently undergone significant revision, leading to important differences between them. We explain how those changes affect the steps you need to take to qualify your instruments.

This article looks at USP Chapter <857>, with new quality control procedures for ultraviolet and visible spectroscopy.

The need to qualify analytical instrumentation, especially in regulated environments such as the pharmaceutical industry, is now so well established that a detailed discussion is unnecessary here.

In the pharmaceutical industry, the analytical quality standards to be observed are published by national and international pharmacopeias, and for instrumental analysis, such as spectrophotometry, an integral part of the standards is that users are able to demonstrate “evidence of control,” such as showing that the instrument used has the performance needed to perform the analysis to the required accuracy and precision. US Pharmacopeia (USP) Chapter <857> and European Pharmacopeia (EP) Chapter 2.2.25 describe quality control procedures for ultraviolet (UV) and visible spectroscopy, and both have recently undergone extensive revision. The revised USP <857> (1) was published on June 1, 2019, and became mandatory on December 1, 2019.

Although the thrust of both standards is in the same direction, the revisions have led to significant differences between them. Before describing the USP changes in detail, it may be useful to outline their major similarities

and differences.

USP and EP: Convergence or Divergence?

Earlier editions of the EP and USP had enough common ground for instrument users to relatively easily devise quality protocols that would demonstrate compliance with both standards. While the updates to USP <857> are essentially an expansion of what went on before, the latest edition of EP 2.2.25 (2) includes changes in scope and detail that may make a common approach to compliance more difficult.

The fundamental change common to both is a new emphasis on demonstrating “fitness for purpose,” that is, that the instrument not only meets its published specification, but that it is suitable for the actual analysis to be performed. In the preceding and previous versions, there was a definitive set of tests, and if your UV-visible system “passed,” you were deemed to be in compliance. Now, the qualification requirement is that the user of the system define the operating range over which the system will be used, and prove compliance within these control limits.

This means that instrument qualification measurements must be representative of the operating conditions to be used for analysis, and where these vary widely between different analyses, implies the use of a wider range of

test materials.

The major difference between the two new standards is their scope. Whereas USP <857> is concerned only with UV-visible spectroscopy, EP 2.2.25 has now been extended to cover other applications of the technology like high performance liquid chromatography (HPLC) detection, diffuse reflectance, and process analytical technology (PAT). There are many other detail differences, and it remains to be seen how instrument users will adjust to the new requirements.

Analytical Quality Control and Instrument Qualification: The USP Approach

The spectroscopic General Chapters in the USP are structured so that each technique-UV-visible (UV-vis) spectroscopy, atomic absorption, infrared, and so forth-is covered by a pair of chapters; one on theory and best practice, and the other on actual procedures, instrument qualification, validation, and verification. The former chapter is informative, and has a chapter number above 1000. The other is mandatory, and, by convention, has a chapter number below 1000. For UV-vis spectroscopy the chapters are <857> and <1857> (3), and they should be read together.

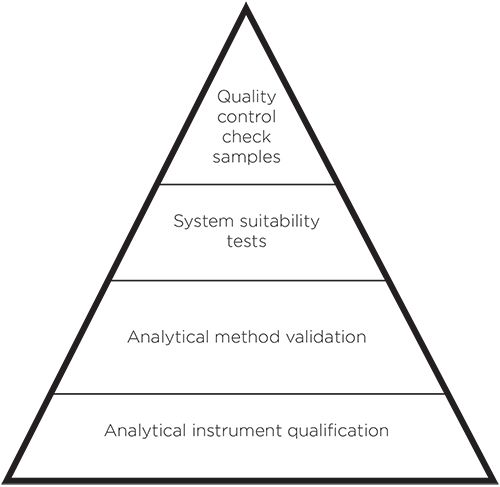

Another General Chapter, USP <1058> (4), describes the overall “best practice” for analytical quality control as a four-level process, where analytical instrument qualification (AIQ) forms the foundation level to the other related pyramidal processes (Figure 1).

Figure 1: USP <1058> components of data quality.

AIQ is itself a four-stage process, known by the well-known acronyms DQ,IQ,OQ, and PQ, standing for design qualification (DQ), installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ). In practical terms, DQ is usually a matter for the instrument supplier, but the user still needs to show that the chosen instrument design (for example, its functional specification) is suitable for the proposed analysis. IQ establishes that an instrument has been properly installed, again often performed by the supplier. OQ is a demonstration of “fitness for purpose,” and as such was often regarded as simply showing that an instrument met its published performance specification. The revised USP <857>, however, now makes it clear that OQ should also show that the performance is adequate for the intended application. PQ verifies that fitness for purpose under actual conditions of use, and demonstrates that it continues to be the case over time.

Normally, a spectrophotometer must be qualified for wavelength, absorbance, stray light, and, where required by the monograph, resolution (spectral bandwidth). In the past, OQ testing of these parameters using a limited number of well-established reference materials could be enough for users (and instrument manufacturers) to claim that an instrument was “pharmacopeia compliant.” The difficulty with this, however, is that a qualification carried out under one set of operating conditions, for example, the UV, might not be valid if the actual analysis is to be carried out at a visible wavelength, where, for example, a different light source might be used. The USP will therefore now require that instruments be shown to meet the performance requirements of the actual analytical monograph or method, and this means that, ideally, OQ should be carried out at or as near as possible to the parameter values to be used for analysis. PQ verifies the fitness for purpose of the instrument under the actual conditions of use over time, and, as such, often involves the preparation and measurement of a standard sample of the actual analyte, thus replicating the analytical measurement. Provided suitable reference materials matching the conditions of use can be found, however, their measurement can form part of PQ as well, particularly for routine performance checks.

USP <1058> also states:

System suitability tests verify that the system will perform in accordance with the criteria set forth in the procedure. These tests are performed along with the sample analyses to ensure that the system’s performance is acceptable at the time of the test.

This implies that instrument performance tests should ideally be performed at the time of each analysis, and that checks carried out at other times may not be acceptable as evidence of control.

One consequence of this more holistic approach is that for some measurements the reference materials traditionally used for instrument qualification may no longer give enough evidence of control. A wider range of reference materials will therefore be required-the latest USP<857> lists several new recommendations-and users will have to choose those most appropriate to their analysis.

Reference Materials for Performance Testing

Until the 1970s, most laboratories used homemade test solutions or proprietary test materials to check the performance of their instrumentation, or relied on the manufacturer to calibrate their instruments as part of routine maintenance. This all changed in 1976 with the publication and subsequent entry into U.S. law of Good Laboratory Practice (GLP) (5), a code that included the requirement for laboratories to qualify their instrumentation using properly characterized test and control materials. At that time, the only available references with internationally recognized and certified calibration values were those from national metrology institutes (NMIs) such as the National Institute of Standards and Technology (NIST) in the United States, whose products were trademarked as Standard Reference

Materials (SRMs).

The advent of GLP, along with other quality standards such as Good Manufacturing Practice (GMP), led to a surge in demand for SRMs that exceeded the production capacity of the NMIs. Commercially produced reference materials were available, but not necessarily accepted by regulatory authorities as being equivalent to SRMs. NIST therefore developed the NTRM (NIST Traceable Reference Material) program (6) to provide a mechanism whereby the measurement values provided with commercially produced materials would be traceable to NIST primary standards. Such materials would be known as Certified Reference Materials (CRMs), and would be recognized by national and international regulators or accreditation bodies such as the American Association for Laboratory Accreditation (A2LA) or the National Voluntary Laboratory Accreditation Program (NVLAP). Another goal of the NTRM program was for commercially produced references to fill gaps in the coverage afforded by SRMs. The success of the program is evidenced by the wide and growing range of CRMs available commercially today. These have largely replaced SRMs for routine instrument qualification use; indeed, some of the original NIST SRMs have been discontinued to be replaced by commercially produced equivalents.

USP <857> states:

“Wherever possible…CRMs are to be used in preference to laboratory-prepared solutions. These CRMs should be obtained from a recognized accredited source and include independently verified, traceable value assignments with associated calculated uncertainty.”

Traceability is defined in the International Organization for Standardization/International Electrotechnical Commission (ISO/IEC) Guide 99:2007 (7) as the

“(P)roperty of a measurement result whereby the result can be related to a reference through a documented unbroken chain of calibrations, each contributing to the measurement uncertainty.”

Measurement uncertainty is a quantitative indication of the quality of a measured result. In instrument qualification, it is necessary to compare the measured value of a given parameter with the expected value of that parameter for the test sample. Clearly, this will be of limited value unless the accuracy of the expected value is known. Laboratory preparation of a reference material can be subject to many variables, and establishing the uncertainty of the final value can be complicated (8). Certified reference materials from an accredited reference material producer, on the other hand, will have been calibrated using reference spectrophotometers that have themselves been qualified against primary standards from NMIs such as NIST, or against primary physical references, thus providing the required traceability. The certificate accompanying the CRM should identify the standards used and state the uncertainty. The usual convention is to state an “uncertainty budget” with a confidence level of 95%. This uncertainty budget will be the cumulative uncertainty of the series of calibrations that have taken place to generate the certified value.

USP <857> also states:

“Recertification should be performed periodically to maintain the validity of the certification.”

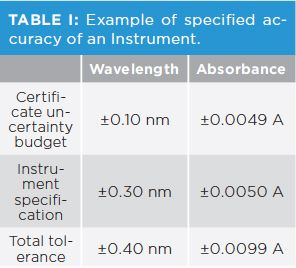

When a CRM is used to qualify an instrument, the total allowed tolerance is the sum of the certificate uncertainty and the instrument manufacturer’s specified accuracy of the instrument, such as the example shown in Table I

If the difference between the measured value and the certified value is less than the total tolerance, the instrument can be judged to be compliant. The difference should also be less than the error permitted by the pharmacopeia or the requirement of the analytical method in use.

CRM suppliers should be properly accredited; the minimum requirement is described in ISO 17034:2016 “General requirements for the competence of reference material producers (9).” This standard, formerly ISO Guide 34, covers quality and administration systems and technical and manufacturing operations. Calibration is a fundamental component of CRM production, and ISO 17034 includes normative references to another standard: ISO/IEC 17025:2017 “General requirements for the competence of testing and calibration laboratories” (10). ISO 17025 specifies the procedures for reporting and evaluating measurement uncertainty, and any competent producer should be accredited to this

standard also.

ISO 17025 accreditation includes a statement of its scope, listing not only the reference materials the laboratory is competent to calibrate but also which measurement techniques it may use for calibration purposes. Purchasers should check that the material to be purchased and the measuring technique are included in the scope of the supplier’s accreditation; accreditation to ISO 17025 could be claimed on the strength of just one material or process, which might not cover the item to be purchased.

While the new edition of USP <857> has widened the range of CRMs available for instrument qualification, situations could still be encountered where no suitable CRM is available commercially. In such cases, if a material with suitable spectral properties can be found, then provided it has the homogeneity and stability required for a reference material, a fully accredited laboratory should be able to certify it for use in

qualification measurements.

There are two basic questions an instrument user should now ask when purchasing commercially produced CRMs:

1. Are they appropriate to the analysis I need to do?

2. Are they suitable for use in my instrument?

Matching the Analytical Requirement

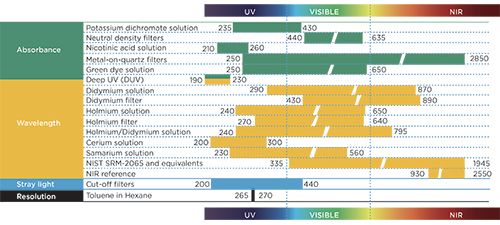

Unless specific instructions are given in the analytical monograph, in general the measurements used for OQ and PQ should bracket the values to be used in the analytical procedure. This can usually be achieved in the UV region, for which a wide range of reference materials is commercially available but can be more challenging at other wavelengths. Figure 2 shows the usable wavelength ranges of materials from one commercial supplier.

Figure 2: Usable wavelength ranges of typical solutions used as CRMs.

Although the wider range of reference materials now listed in USP <857> will satisfy most requirements, it may still arise that the materials listed cannot provide qualification at the operating conditions required for a specific analysis. In such cases, the list need not be regarded as exclusive; users can employ any suitable CRM provided it meets the required criteria for stability, homogeneity, and traceability, and CRMs from a properly accredited supplier should meet those criteria. Indeed, such a supplier should be able to calibrate suitable materials to customer requirements.

References for Wavelength Qualification

The standard requires that at the instrument is qualified in each operational range where it is intended for use. Ideally, wavelength should be qualified at values that bracket the analytical wavelength. Holmium oxide solution was the traditional choice for wavelength qualification, but its lack of peaks below 240 nm has led to the recommendation of cerium oxide solution for lower wavelengths, with peaks down to 201 nm. For those needing qualification at even lower wavelengths, CRMs are commercially available that provide certified peaks down to 191 nm. The spectra of many rare earth elements exhibit sharp peaks, so that instrument bandwidth will influence the measured wavelength value. Good CRMs will have wavelengths certified at different bandwidth values, and the user should choose the bandwidth specified in the analytical monograph. At the other end of the bandwidth scale, some simple instruments may be unable to resolve these sharp bands, and for these cases a specially formulated “green dye solution,” offered by one reference material producer, is a CRM that can be used to qualify wavelength (and absorbance) at bandwidths up to 12 nm.

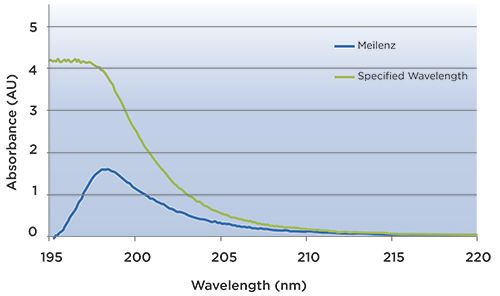

Figure 3: Potassium chloride solution spectra using both stray light procedures.

Several rare earth element references, such as holmium and didymium, are available incorporated into glass filters. These are perhaps more robust than cell-based liquid references, but wavelength values can vary from melt to melt so such filters should be individually certified.

Atomic spectral lines are a primary physical standard and the ultimate wavelength reference, with mercury vapor lamps the source most often cited. USP <857> however, cautions that:

“The arc of the atomic emission source, or its image, needs to be located on the same optical path as the image of the primary light source of the spectrometer; thus, it can be used only in spectrometers that can be operated in a single-beam intensity mode and practically should be implemented only on a system designed to accommodate these sources.”

Many instruments using deuterium lamps as UV light source have the possibility to use emission lines from this lamp as an indication of wavelength accuracy. There are, however, only two lines available, at 486.00 nm and 656.10 nm in the visible region, so while a useful routine check, they are unsuitable for UV qualification.

References for Absorbance Qualification

As for wavelength, absorbance qualification measurements should bracket the values expected in the method. The USP now requires that absorbance linearity is checked, with measurements at a minimum three absorbance levels spanning the expected range, and at the wavelengths to be used in the analysis. Absorbance precision can be determined from the same measurements, as the standard deviation from the mean of at least six replicate measurements made at the upper and lower limits of the operational range.

In the 2015 edition, USP <857> cited only two reference materials for absorbance qualification; potassium dichromate solutions for the UV, and neutral density glasses for the visible region. The new edition cites two more, nicotinic acid solutions and metal-on-fused-silica filters, to cover a wider wavelength range. The use of potassium dichromate (at 600 mg/L) is also extended to 430 nm in the visible region.

Nicotinic acid is now recommended for wavelengths below the usable range of potassium dichromate, down to 210 nm. Metal-on-fused-silica filters have the attraction of a wide usable range, with an essentially flat spectrum from 250 nm to 635 nm, and are available from some suppliers with traceable calibrations extending into the near-infrared, up to 2850 nm. There is, however, a potential issue that is not mentioned in <857>: As these filters attenuate the incident radiation partly by reflection, inter-reflections could be generated within the sample compartments of some spectrophotometers that could affect measurement accuracy. Potential purchasers should check with their instrument’s manufacturer that it is compatible with this type of filter.

References for Stray Light Qualification

The wavelength range of the reference materials available for stray light qualification is more limited. Fortunately, however, much pharmaceutical analysis is performed in the UV region, for which references do exist. Increasing stray light may indicate deterioration of optical surfaces or light sources, and, as such, USP <857> now recommends stray light checks as part of PQ.

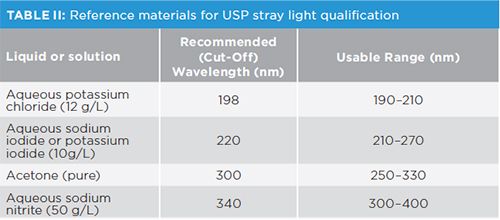

There are two USP methods for the detection of stray light. One is the traditional specified wavelength measurement of a filter solution that cuts off all light below a certain wavelength so any light detected below that wavelength must be stray light (Procedure B). This method was allowed by the 2015 version of USP <857>, but the cutoff wavelength was not stated in the standard; it is now included (see Table II), and is the wavelength at which the absorbance exceeds 2 AU. Used with high-performance instruments having very low stray light, however, these solutions will give very high, perhaps off-scale, absorbance readings below the cut-off wavelength when measured against the usual water blank. A quantitative result might then require a two-stage measurement, using back-off of some kind, that might itself introduce errors.

The alternative filter ratio, or Mielenz, method (Procedure A) was introduced in the 2015 edition of USP <857>, and is useful in such situations. In this method, a 10 mm path length cell of the reference liquid is measured against a 5 mm path length cell containing the same liquid, giving automatic back-off and an on-scale peak from which the stray light can be calculated. This differential absorbance measurement produces a peak in the spectrum and a value of 0.7 AU for this peak equates to the 2.0 AU limit of the specified wavelength method. The test liquids used in both methods are identical, and cover wavelengths from 190 to 400 nm. The USP does not require stray light to be qualified above 400 nm.

References for Resolution (Bandwidth) Qualification

USP <857 > states: “For most compendial quantitative purposes, an SBW of 2 nm or less is sufficient.” Only one test material is recommended for resolution, 0.02% toluene in hexane. Measured against a hexane blank, the spectrum of this solution has a maximum absorbance at about 269 nm and a minimum at about 266 nm. The ratio of these absorbance values is a measure of the resolution, and for a 2 nm bandwidth the ratio should be not less than 1.3.

Conclusions

The new edition of USP <857> requires a more holistic approach to the qualification of UV and visible spectrophotometers. OQ should be performed using operating conditions as close as possible to those that will be encountered in the proposed analyses. To assist users with compliance, the USP now lists an expanded range of commercially available certified reference materials for qualification measurements and continues to recommend their use in preference to laboratory-prepared references. These CRMs can also find a role in on-going PQ and System Suitability testing.

References

- <857> Ultraviolet-Visible Spectroscopy,USP 42-NF37 Second Supplement (2S), (United States Pharmacopeia (USP), Rockville, Maryland, 2019).

- 2.2.25 Absorption Spectrophotometry, Ultraviolet and Visible 42, 10th Edition (European Pharmacopoeia [Ph. Eur.], European Directorate for the Quality of Medicines & HealthCare [EDQM], Strasbourg, France, 2020).

- <1857> Ultraviolet-Visible Spectroscopy” USP 38-NF33 (United States Pharmacopeia (USP), Rockville, Maryland, 2015).

- <1058> Analytical Instrument Qualification, USP 41-NF36 ( (United States Pharmacopeia (USP), Rockville, Maryland, 2018).

- Good Laboratory Practices (GLP) for Non-Clinical Laboratory Studies (Code of Federal Regulations, 21 CFR Part 58, Silver Spring, Maryland).

- Technical Specifications for Certification of Spectrophotometric NTRMs Special Publication SP260-140 (National Institute of Standards and Technology, Gaithersburg, Maryland, 2000).

- ISO/IEC Guide 99:2007 International vocabulary of metrology -- Basic and general concepts and associated terms (VIM) (International Organization for Standardization [ISO], Geneva, Switzerland).

- C. Burgess, Pharm. Tech.40(2), 36–40 (2016).

- ISO 17034, General requirements for the competence of reference material producers (International Organization for Standardization [ISO] Geneva, Switzerland, 2016).

- ISO/IEC 17025 General requirements for the competence of testing and calibration laboratories (International Organization for Standardization [ISO], Geneva, Switzerland 2017).

Nathan Hulme is a director at Starna Scientific Ltd. in Hainault in the United Kingdom. Direct correspondence to: nathan@starna.com

Chinese Researchers Develop Dual-Channel Probe for Biothiol Detection

April 28th 2025Researchers at Qiqihar Medical University have developed a dual-channel fluorescent probe, PYL-NBD, that enables highly sensitive, rapid, and selective detection of biothiols in food, pharmaceuticals, and living organisms.