High-Definition Infrared Imaging

Thermo Electron Corp.

There are several methods for improving spatial resolution in infrared hyperspectral imaging. These methods and their associated benefits and disadvantages are described in this note.

The early 21st century is the age of digital imaging. From multimegapixel digital cameras to high-definition television monitors, the race is on to provide ever higher resolution imaging devices. In these products, the resolution is defined by the number of pixels, or individual picture elements, in a given image. For example, a computer display of 1280 × 1024 pixels is considered high resolution when compared to one containing a mere 800 x 600.

In infrared hyperspectral imaging, the same basic rules apply. The more pixels that an image of a given sample area contains, the greater the image fidelity. However, the resolution of an image is ultimately limited by the imaging optics and the wavelengths of light that comprise the image. As infrared light has much longer wavelengths than visible, an infrared image can never have the resolution of a good video micrograph. Then again, a video micrograph can never have the resolution of an electron micrograph obtained with far shorter wavelengths still. To a first approximation, the resolution of an image can continue to be improved until the pixel size approaches the shortest wavelength of the light that generated that image, provided that suitable optics are employed. In the case of infrared imaging, this equates to a few microns. However, high resolution images come at a price. For example, as the number of pixels in an image increases, so does the file size associated with it. Anyone who has received a high resolution picture from a five megapixel digital camera as an e-mail attachment over a 56k modem will be familiar with this. In infrared hyperspectral imaging, the problems associated with high-resolution imaging are somewhat more serious and include, but are not limited to, large file sizes.

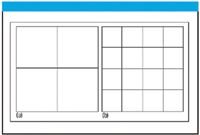

In order to understand the issues surrounding high-definition infrared imaging, consider the following example. A low-resolution image of a sample area of 40 × 40 microns is described by four pixels of 20 microns a side, as shown in Figure 1a.

Figure 1. 40 Ã 40 sample area represented by (a) four 20 x 20 pixels and (b) sixteen 10 Ã 10 pixels.

A high-resolution image of the same area is described by 16 pixels of 10 microns square, as shown in Figure 1b. There are three possible hardware solutions to get from the low- to the high-resolution image.

1. A matched objective and condenser set is used that has twice the magnification of the low-resolution set. The detector views a smaller area of the sample and so, to obtain an image of the 40 × 40 micron sample area, four frames are acquired and stitched together. The advantage of this approach is that the condenser, as its name implies, condenses the light from the source onto the sample. As such, the higher magnification condenser focuses the light onto a smaller sample area. Therefore, each detector element 'sees' about the same amount of light in both cases.

2. Only one condenser/objective set is used but a 2× magnifying optic is placed between the objective and the detector. As in Figure 1, four frames are acquired to represent the entire sample area. The advantage of this technique is that it is relatively inexpensive and simple to operate. However, the disadvantage is that the magnification happens after the condenser. Therefore the light intensity striking each detector pixel is much lower in the high-resolution case, reducing signal-to-noise and thereby increasing collection times beyond those suggested by simple geometry.

3. Use one set of optics, but use a camera with as many 4× the number of pixels per unit area. This has the advantage that only one frame is required to image the sample area. However, as in Figure 2, the light striking each pixel is much reduced compared to the low-resolution case. High pixel count, or 'large format', cameras for infrared use have lower read-out speeds than their smaller counterparts. Therefore, the apparent speed advantage of large cameras over smaller ones is not as great as may first be perceived.

Figure 2. Area of photoresist target shown as (a) a video micrograph, (b) an infrared image at standard resolution and (c) an oversampled high-definition infrared image.

In all three cases, file sizes increase and acquisition times get longer as resolution increases. As there is a significant trade-off between resolution and data collection time, many imaging systems include options for altering resolution.

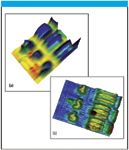

A fourth technique for resolution enhancement in infrared imaging does not involve either additional optics or large format cameras. Introduced in OMNIC™ Atlμs™ 7.2 software, oversampled high-definition infrared imaging offers the ability to vary image fidelity via software-controlled data acquisition. As with most image acquisition schemes, the system builds an image by collecting a number of contiguous frames from a sample that is moved step-wise relative to the camera and stitches them together to produce a single large image. In oversampled mode, the software moves the sample a fraction of the apparent pixel size. In the example above, in order to obtain the high resolution image, the first frame would be acquired and then two subsequent frames would be collected with an off-set of 1/4 frame (or 1/2 pixel) in the X and Y direction respectively. Each pixel is then registered to its correct spatial coordinates in order to build the final image. Images collected with and without oversampling are shown in Figure 2. The data is presented in 3-D in Figure 3.

Figure 3. Three-dimensional renderings of (a) standard image and (b) oversampled hgh-definition image.

Both infrared images were collected with the same optics on the Nicolet™ Continuμm™ XL FT-IR imaging microscope. This software-based approach to high-definition imaging provides two significant advantages over the optical techniques described above.

1. As the dimensions of the sample observed by each detector element are constant, the light striking the detector, and therefore the signal-to-noise is largely independent of resolution.

2. As the resolution is software controlled, a range of resolutions may be provided that are not limited by the availability of optics or cameras.

Conclusions

As image resolution increases so does acquisition time with any infrared imaging system. Therefore, it is beneficial to have the ability to acquire a low-resolution image for survey work and then to obtain high-resolution images for more detailed investigations. Oversampled, high-definition infrared image acquisition provides a range of resolutions without the need for additional optics or cameras and does not sacrifice signal-to-noise for resolution.

Thermo Electron Corporation

5225 Verona Road, Madison, WI 53711

Tel. (800) 532-4752, Fax (608) 273-5046

Thermo Fisher Scientists Highlight the Latest Advances in Process Monitoring with Raman Spectroscopy

April 1st 2025In this exclusive Spectroscopy interview, John Richmond and Tom Dearing of Thermo Fisher Scientific discuss the company’s Raman technology and the latest trends for process monitoring across various applications.

A Seamless Trace Elemental Analysis Prescription for Quality Pharmaceuticals

March 31st 2025Quality assurance and quality control (QA/QC) are essential in pharmaceutical manufacturing to ensure compliance with standards like United States Pharmacopoeia <232> and ICH Q3D, as well as FDA regulations. Reliable and user-friendly testing solutions help QA/QC labs deliver precise trace elemental analyses while meeting throughput demands and data security requirements.