Microparticles in Focus

High-resolution measurements of particles are of great interest in many fields of application. With ParticleScout, WITec has developed a tool that makes it possible to find, classify, and identify particles automatically.

We encounter microparticles in many everyday products and in the environment. The analysis of fragments between 0.1 µm and 1 mm is challenging. Large areas have to be scanned, and even the most miniscule components must be recognized. The particles of interest need to be determined, classified according to selected properties such as shape or size, and finally their chemical composition has to be identified. The easiest and quickest way to perform this task is to use an automated and standarized microscopic inspection and chemical analysis. WITec ParticleScout, an advanced microparticle analysis tool, in combination with Raman microscopy, now offers this capability.

Experimental conditions

Two experiments were carried out with ParticleScout coupled to an alpha300 R confocal Raman microscope. Raman spectra were analyzed with the TrueMatch Raman database management system (all WITec). The excitation wavelength was 532 nm.

Sludge from a wastewater treatment plant was analyzed for the presence of microplastic particles (sample courtesy of Dieter Fischer, Leibniz Institute of Polymer Research, Dresden, Germany). Fifty grams of the sludge was pretreated and purified, then filtered in a two-stage process through silicon filters with 50- and 10-µm pore sizes, respectively. Raman spectra of a subset of found particles were acquired. In a second experiment tungsten disulfide (WS2) nanoparticles several micrometers long and a few hundred nanometers thick were examined (sample courtesy of Reshef Tenne, Weizmann Institute, Israel, provided through the Institute of Physical Engineering at Brno University of Technology [CEITEC], Czech Republic). Fragments shorter than 5 µm were located, then nanowires were classified by their aspect ratio, which was greater than 2.5.

Results

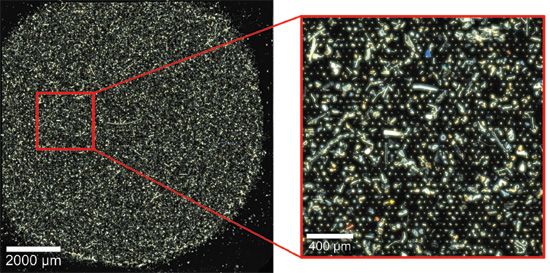

Microparticles were sucessfully discovered and classified using confocal white-light microscopy with the ParticleScout software. In the sludge sample, Raman spectra were acquired from 18,000 of the tens of thousands of microparticles that could be seen in the dark-field microscopic image (Figure 1). Forty six were plastic fragments: Polyethylene (25 pieces) and polypropylene (12 pieces) were the most abundant types of microplastic. Their sizes varied from 5 to more than 50 µm (circular equivalent diameter). Additionally, many different pigments and titanium dioxide particles were found.

Figure 1: A 10 × 10 mm2 dark-field overview of a filter with microparticles from sludge was stitched together from 1089 images (left). From the selected area (right), Raman spectra were acquired from 18,000 fragments. The particles were automatically located and measured using the ParticleScout software.

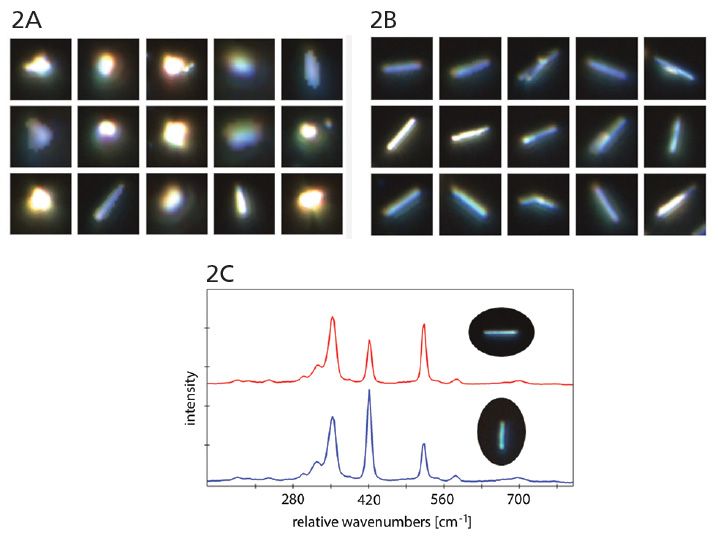

In the WS2 sample 3,135 nanoparticles were detected and imaged (Figure 2). From these, 218 were classified as nanowires according to their aspect ratios. The Raman peak at 420 relative wavenumbers (cm-1) indicates the orientation of the nanowires with respect to the polarization of the laser light.

Figure 2: Under the microscope, WS2 nanoparticles were imaged automatically with ParticleScout. A subset of 3135 detected fragments is shown (A). Of these, 218 granules had an aspect ratio of greater than 2.5 and were therefore classified as nanowires (B). (C) shows Raman spectra for two nanowires with different orientations. The intensity at 420 relative wavenumbers depends on the angle between the nanowire and the polarization of the laser.

Conclusions

Using a confocal Raman microscope equipped with ParticleScout, large numbers of particles were easily located and classified into categories, as demonstrated using two samples from the fields of microplastic pollution and materials science. Raman spectra were measured automatically for all particles of interest. The seamlessly integrated TrueMatch database management software enabled quick identification of the particles. Reports summarize the results and describe the materials in terms of physical properties.

WITec GmbH

Lise-Meitner-Str. 6, 89081 Ulm (Germany)

tel +49 (0)731 140700

Website: www.witec.de