Advances in Infrared Microspectroscopy and Mapping Molecular Chemical Composition at Submicrometer Spatial Resolution

Spectroscopy

Infrared microspectroscopy has led to important advances in a wide range of fields, as biologists, chemists, geologists, materials scientists, microscopists, and spectroscopists around the world have awakened to the values of nanotechnology. The small world is getting larger.

Although 69 years have passed since infrared spectroscopy and microscopy were first united, these technologies continue to advance. Since 1983, the catalysts for rapid commercial growth and broad applications were Fourier transform infrared (FT-IR) spectrometers, resulting in advances in all reflecting microscope optics and high sensitivity detectors. Today, quantum cascade lasers and scanning microscopy are emerging technologies that are demonstrating the ability that drastically improves resolving power and quality of spectral data collected from submicrometer-sized samples. This installment of "Molecular Spectroscopy Workbench" is a brief history and reports on the status of infrared microspectroscopy and its future promise.

Art conservationists, biologists, chemists, environmentalists, forensic scientists, geologists and materials scientists need the combination of chemical composition and morphological structure to analyze complex matter, solve problems, or identify small particulates. Scanning electron microscopy (SEM) provides imaging of morphological structure, and can be combined with X-ray spectroscopy for elemental analysis. However, molecular composition may only be inferred from X-ray spectra by quantitative elemental analysis. Infrared microspectroscopy provides both molecular chemical information and imaging of morphological structure, but is limited for elemental analysis. The success of both of these techniques is dependent on their ability to provide high quality spectral data at the highest possible spatial resolution. Recent discoveries in infrared microspectroscopy are advancing this approach to new levels of spectral quality and resolving power.

First, a brief history of infrared microspectroscopy. In 1949, two publications (1,2) heralded the practicality of infrared spectroscopy. Perkin-Elmer Corp. introduced the first commercial infrared microspectrometer in 1953, the Model 85 (3). A single-beam, sodium chloride prism, dispersive infrared spectrometer was coupled to an all-reflective light microscope. A four-bladed variable aperture located in the primary image plane defined the area of the sample that produced the transmission spectrum. The detector was a bolometer and the intensity of transmitted infrared radiation at each wavelength was plotted by a strip chart recorder. A string connected to the variable slit in the spectrometer was attached to a cardioid cam, increasing the slit width to maintain a level of incident intensity as the wavelength was increased. However, the spectral resolution varied across the spectrum. Obtaining a transmittance spectrum required recording an Io and Isample single beam spectra, tabulating the intensity of each at periodic wavelengths, calculating the Isample/Io ratio, and replotting the data. Although this system was a novel research tool, it was not a commercial success.

Infrared microspectroscopy was essentially dormant until 1978, when V. Coats introduced the Nanospec IR20 microspectrometer. By combining a microprocessor computer, a liquid nitrogen–cooled solid-state detector, a variable-wavelength interference filter monochromator, and an all-reflecting optical microscope, Coats resurrected interest in IR microspectroscopy. His revolutionary contribution was overshadowed when Fourier transform infrared (FT-IR) spectrometers became commercially available. Attaching all reflecting microscopes to FT-IR spectrometers let the genie out of the bottle. Three decades of improvement to FT-IR microspectrometers, and sustained growth applications, established infrared microspectroscopy as a vital analytical technique.

The motto "good enough is never good enough" is a driving force for advancement. In microspectroscopy, improving spectral quality, detection limits, and resolving power are challenges. The quality of an infrared spectrum is limited by the intensity of incident radiation, wavelength resolution, sample size, and detector sensitivity. Detection limits are dependent on the sample's area, thickness, and composition. Resolving power-the minimal distance of separation of two objects-using visible or infrared radiation is limited by wavelength, numerical aperture, optics and contrast. The resolving power of spectral maps created using an FT-IR microspectrometer is limited by the wavelength and spectral contrast. The spectral quality and contrast of maps are reduced as the dimensions of the sample are reduced. When spectra are collected from a diffraction-limited point using an FT-IR spectrometer with a 1200 K ceramic source, spectral quality and contrast are reduced. Higher intensity sources, such as the synchrotron or quantum cascade (QC) lasers, have demonstrated improved spectral quality and mapping speed of performance at the wavelength diffraction limit.

United States Patent 457,709, filed April 4, 1994, lists the inventors F. Capasso, A.Y. Cho, J. Faist, A.I. Hutchinson, S. Luryi, C. Sirtori, and D.L. Sivco (4). The abstract of this patent states: "This application discloses, to the best of our knowledge, the first unipolar laser. An exemplary embodiment of the laser was implemented in the GaInAs/AlInAs system and emits radiation of about 4.2 µm wavelength. Embodiments in other material systems are possible, and the lasers can be readily designed to emit at a predetermined wavelength in a wide spectral region. We have designated the laser the 'Quantum Cascade' (QC) laser."

The foundation for the QC laser is the use of intersubband transitions for amplification of radiation (5). Over the past two decades, an abundance of QC laser research and development has been taking place (6). Today, QC lasers are commercially available from several sources. The power output has increased, and the operating temperature can be above room temperature. They can operate in either a continuous or pulsed mode. They are capable of emitting mid-infrared radiation in the 2857–400 cm-1 range. The successful application of QC lasers in medical, biological, environmental, communication, and chemical research has driven their expanding growth.

QC laser technology provides a new direction for advancing infrared microspectroscopy. The major avantages of QC lasers for infrared microspectroscopy are broad tunablity over the mid-infrared wavelength range, intensity, low divergence, and high frequency rate. Three approaches have been advanced for improving spatial resolution and quality of spectral data using QC lasers. The first approach was to replace the infrared radiation source with a broadly tunable QC laser for an all-reflecting microscope. The second approach was to couple the broadly tunable QC laser with scanning probe microscope to detect the photothermal expansion created by a modulated QC laser beam. The third approach was to use a visible light probe to detect the photothermal expansion created by a modulated QC laser beam. These three approaches are addressed chronologically.

Replacing the thermal source with QC lasers was first demonstrated by the R. Bhargava research group at University of Illinois in Urbana, Illinois, in 2012. An in-house infrared microspectrometer was developed that used an array of tunable QC lasers supplied by DRS Daylight Solutions, tunable over the range of 1738 –1570 cm-1 as a transmitted radiation source (7). This microspectrometer system demonstrated that major advantage of using the QC laser over FT-IR was the speed of collection spectral maps using a single wavelength. In 2014, DSR Daylight Solutions introduced the first commercially available QC laser–powered chemical imaging microscope for IR spectroscopy. The Spero system (DSR Daylight Solutions) proclaimed real time, high-throughput spectral imaging enabled by ultrahigh-brightness QC laser technology. The spectral range of the Spero imaging system was expanded to 1800–900 cm-1. This expanded range was a significant development. The initial applications these advances were in label-free histochemical imaging, and classification in tissues (8–11).

Combining QC laser technology with scanning probe microscopy (SPM) is the invention of C. Prater and K. Kjoller in 2011 (12–14). This invention makes possible a novel method for obtaining nanometer resolving power and high-resolution infrared spectra. The method includes using infrared radiation from a quantum cascade laser directed onto a small area of a sample. The QC laser array is tuned over a broad range of infrared wavelengths. When the sample adsorbs radiation of a certain wavelength, the energy of the adsorbed photon is transformed into heat, causing a thermal expansion of the sample. This photothermal event is monitored using a scanning probe microscope. The probe of the microscope is mounted on a cantilever. The QC laser is operated in a pulsed mode, creating a periodic motion of the cantilever. The amplitude of this osculation is a measure of the magnitude of the photothermal event. The magnitude of the thermal event plotted against the wavelength infrared radiation to produce a photothermal IR (PTIR) spectrum. This unique combination of QC laser and scanning probe technologies produces infrared spectra that are consistent with spectra collected by FT-IR. Photothermal IR is also known as atomic force infrared spectroscopy (AFM-IR).

AFM-IR advanced infrared spectroscopy from a resolving power limited by the wavelength of the infrared radiation to a limit defined by the tip size of the scanning probe, a change of scale from ~10 µm to ~10 nm. QC lasers provide the intensity to produce photothermal events that the scanning probe microscope detects to produce infrared spectra at subnanometer spatial resolution. The rapid scanning of the sample, while the it is exposed to a single wavelength of infrared radiation, produces molecular composition maps with unprecedented resolution.

AFM-IR spectroscopy was the basis for the development by Anasys Instruments of the first commercial instrument, the nanoIR system (Anasys Instruments). The nanoIR instrument became available in 2012. In the past six years, AFM-IR technology has become a prominent tool in nano research in the biological, medical, chemical and materials sciences (14-16). The best evidence for the success of AFM–IR is the recent acquisition of Anasys Instruments by Bruker.

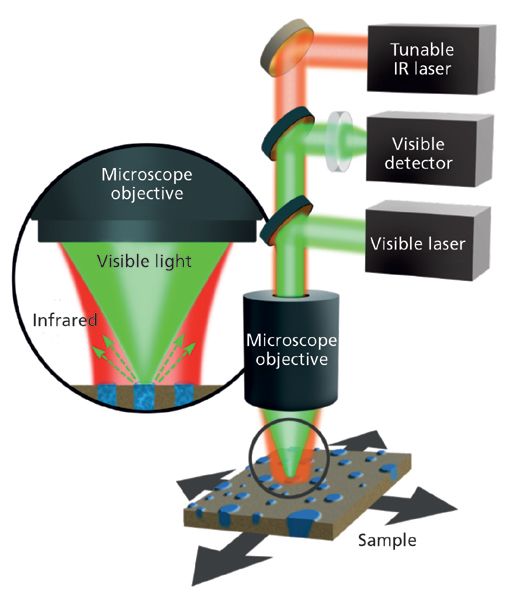

Figure 1: A schematic diagram illustrating the optical components of the mIRage photothermal infrared microspectrometer.

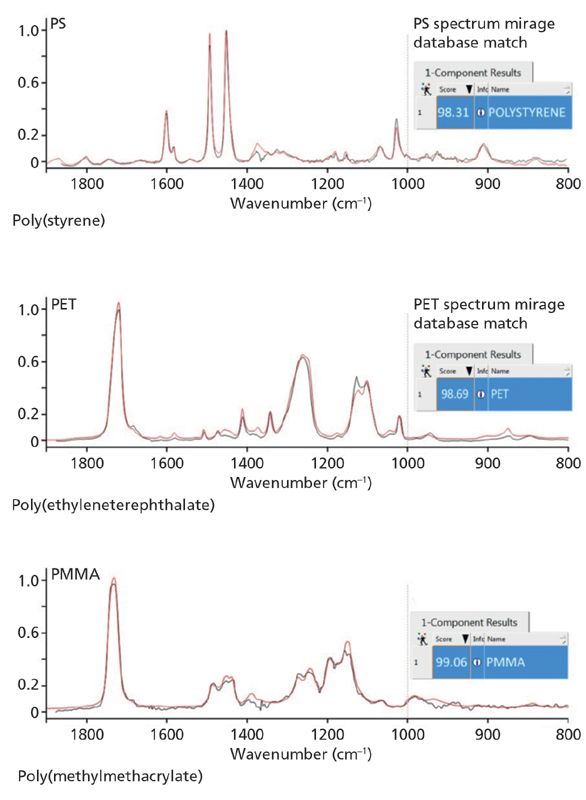

Replacing the mechanical probe of a SPM with a focused monochromatic visible light probe to detect the photothermal event created by the incident infrared radiation provides a new instrumental approach to infrared microspectroscopy. The Anasys group developed this approach and created a new company, the Photothermal Spectroscopy Corp. The company's new mIRage instrument fills the resolving power gap between FT-IR and AFM-IR. At the heart of this approach, the photon probe is focused on the sample's surface, and is coaxial and confocal with the mid-infrared radiation. This relationship is illustrated in Figure 1. The infrared source is a broadly tunable pulsed QC laser. The photothermal event, produced when the sample absorbs the infrared radiation, creates a change in the reflected or scattered light's intensity. This change in the visible light intensity is proportional to the absorption of infrared radiation used to create a photothermal infrared (O-PTIR) spectrum. The O-PTIR spectra, collected using the mIRage micro, are comparable to spectra in the KnowItAll Spectra FT-IR database (Bio-Rad). Illustrated in Figure 3, the O-PTIR spectra are well matched to the database spectra, all with a correlation factor above 98%.

Figure 2: Infrared absorption spectra of poly(styrene) (PS), poly(ethyleneterephthalate) (PET), and poly(methylmethacrylate) (PMMA), collected using the mIRage photothermal infrared microspectrometer compared against the KnowItAll FT-IR spectral database (Bio-Rad) (in red).

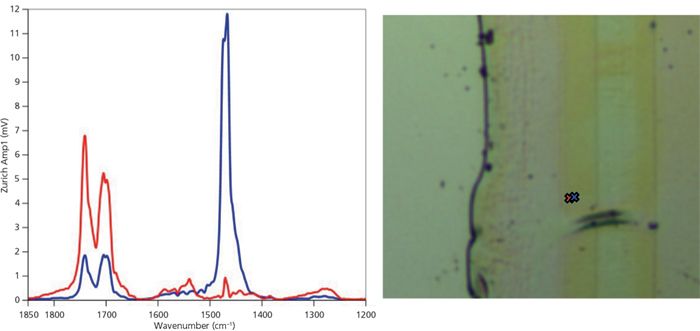

With the optical probe system of the mIRage system, the resolving power in spectral imaging is improved to ~0.45 nm. Importantly, the resolving power in spectral images is limited by the wavelength of the visible-light laser and is constant across the infrared spectral range. In spectral images collected using FT-IR or QC laser micro spectrometers, the resolving power is a function of the infrared radiation, and therefore varies across the spectrum.

Figure 3: (Left) Photothermal infrared spectra collected using the mIRage system. (Right) Micrograph showing a digital image record of the cross-section of multilayered laminated sample. Two points, 500 nm apart, are marked with red and blue X's. The infrared spectra were collected at the indicated locations.

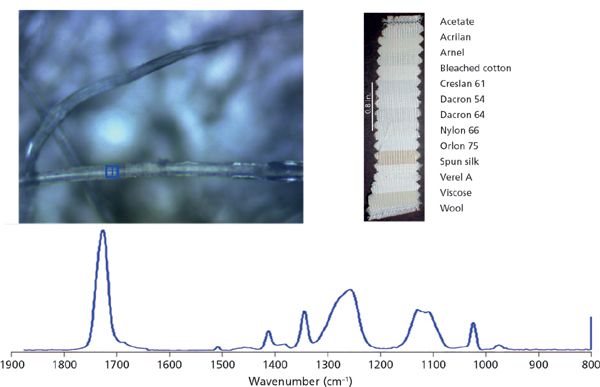

Operating in the noncontact reflection mode simplifies sample preparation. For example, Figure 4 shows the spectrum an individual fiber in a fabric acquired directly with no special sample preparation. Thick samples can be analyzed in the single point mode. Mapping of large areas require flat surfaces normal to incident radiation. The variety of samples, improved resolving power, quality of O-PTIR spectra and ease of sample preparation, dramatically advance microspectroscopy.

Figure 4: Optical image and O-PTIR spectrum of test fabric consisting of 13 different textile materials all woven together into a single sample. Data collected using the mIRage instrumentThe blue cross indicates the location where the O-PTIR spectrum was collected.

Summary

There are numerous examples of applications of infrared microspectroscopy in all academia, national laboratories, government agencies, hospitals, industries; all of them benefiting from the advances in the field (17–19). It is stimulating to see the advances of infrared microspectroscopy. The history of progress of this powerful and diverse technology is very impressive. It is great to be part of the evolution from its humble beginnings to major factor in our growing technology. Biologists, chemists, geologists, materials scientists, microscopists, and spectroscopists around the world are awakening to the values of nanotechnology. The small world is getting larger.

References

(1) R.C. Gore, Science 110, 710–711 (1949).

(2) D.D. Barer, Nature 163, 198–201 (1949).

(3) V.J. Coats, A. Offner, and E.H. Siegler, J. Optical Soc. of America 43(11) 984–966 (1953).

(4) F. Capasso et al., US Patent, 5,457,709, Unipolar Semiconductor Laser, 1994.

(5) F. Capasso et al., US Patent, 5,936,989, Quantum, 1997.

(6) M.S. Vitiello, Optics Express23(4), 5167–5182 (2015).

(7) K. Yeh, M. Schulmerich, and R. Bhargava, "Mid-infrared Microspectorscopic Imaging with a Quantum Cascade Laser," in Next Generation Spectroscopic Technologies VI, edited by M.A. Druy and R.A. Crocombe, Proc. of SPIE vol. 8726 8720E-1(2013).

(8) K. Yeh, S. Kenkel, J-N. Liu, and R. Bhargava, Anal. Chem. 87(1), 485–493, (2015).

(9) H. Sreedhar, V.K. Varma, F.V. Gambacorta, G. Guzman, and M.J. Walsh, Biomed.Opt. Express7(6), 2419–2424 (2016).

(10) J.B. Bird and J. Rowlett, "A Protocol for Rapid, Label-free Histochemical Imaging of Fibrotic Liver," Analyst DOI:10.1039/c6an02020a (2016).

(11) C. Kuepper et al., "Quantum Cascade Laser-Based Infrared Microscopy for Label-Free and Automated Cancer Classification in Tissue Sections," Scientific Reports, DOI:10.1038/s41598-018-26098-w (2018).

(12) C. Prater and K. Kjoller, US Patent 8,680,467 (2013).

(13) L. Brown, M. Davanco, Z. Sun, A. Kretinin, Y. Chen, J.R. Matson, I. Vurgaftman, N. Sharac, A.J. Giles, M.M. Fogler, T. Taniguchi, K. Watanabe, K.S. Novoselov, S.A. Maier, A. Centrone, and J.D. Caldwell, Nano Lett. 18, 1628–1636 (2018).

(14) F. Lu and M.A. Belkin, Optics Express 19(21),19942–19947 (2011).

(15) M. Belkin, F. Lu, V. Yakolev, C. Prater, K. Kjoller, and M. Raschke, US Patent US8869602B2, High frequency deflection measurement of IR absorption (2014).

(16) F Lu, M. Jin and M.A. Belkin, Nature Photonics 8, 307–312 (2014).

(17) F. Huth, Al. Govyadinov, S. Amarie, W. Nuansing, F. Keilmann, and R. Hillenbrand, Nano Lett. 12(8), 3973–3978 (2012).

(18) A. Dazzi and C.B. Prater, Chem. Rev. 117(7), 5146–5173 (2017).

(19) J. Chae, Qi. Dong , J. Huang, and A. Centrone, Nano Lett. 15(12), 8114–8121 (2015).

John A. Reffner is a professor at John Jay College of Criminal Justice in New York, New York. Direct correspondence to: jreffner@jjay.cuny.edu

A Proposal for the Origin of the Near-Ubiquitous Fluorescence in Raman Spectra

February 14th 2025In this column, I describe what I believe may be the origin of this fluorescence emission and support my conjecture with some measurements of polycyclic aromatic hydrocarbons (PAHs). Understanding the origin of these interfering backgrounds may enable you to design experiments with less interference, avoid the laser illuminations that make things worse, or both.

Raman Microscopy for Characterizing Defects in SiC

January 2nd 2025Because there is a different Raman signature for each of the polymorphs as well as the contaminants, Raman microscopy is an ideal tool for analyzing the structure of these materials as well as identifying possible contaminants that would also interfere with performance.