Identification of Graphite Mechanical Behavior and Dislocations by Micro-Raman Microscopy

Spectroscopy

In this study, micro-Raman microscopy was used to examine graphite mechanical behavior through the evolution of dislocation defect density and the resultant deformation (strain) in graphite components. The increasing strength of the Raman optical phonon modes linked with a generous number of dislocations indicates the potential capability of Raman spectroscopy to help develop a mechanistic understanding of the complex mechanical behavior of graphite for use in many industries and applications.

Using micro-Raman microscopy, we examine graphite mechanical behavior through the evolution of dislocation defect density and the resultant deformation (strain) in graphite components. The strengthening of the Raman-active G and D phonon modes observed in the Raman spectrum under loading condition is attributed to an increase in the number of dislocations in the graphite structure. The increasing strength of the Raman optical phonon modes linked with a generous number of dislocations indicates the potential capability of the Raman spectroscopy technique to help develop a mechanistic understanding of the complex mechanical behavior of graphite for use in many industries and applications. The identification of deformation behavior and a dislocation-mediated deformation process in graphite is the ultimate aim of our research as well as to develop a better understanding of the graphite mechanical behavior, which is important to clean nuclear fission energy technologies.

Graphite is a potential material for the development of next-generation nuclear energy systems (1). The physical processes characterizing the failure of graphite structures require experimental insights to describe nucleation and propagation of dislocations and their interaction. There is little data describing the physical mechanisms responsible for initiating failure in graphite. The aim of this research is to explore the Raman spectroscopy and microscopy techniques to better understand how dislocations deform the bulk crystals associating to the graphite mechanical behavior and the way graphite structure accommodates the strain before failure. The developed technique is used for graphite materials to quantify dislocation density in the structure derived from the strengthening and shifting of Raman peaks dependent on the loading conditions. The applied external stress involves the start of movement of the existing dislocations, the generation of new dislocations, and the subsequent interaction among them through the Frank-Read mechanism (2). The motion and interaction of dislocations tend to happen on available slip planes along various directions in a hexagonal crystal system for components failure (3).

The progressive evolution of dislocations in graphite bulk crystals leads to little gross plastic deformation before failure under externally applied stresses. At a microscopic level, deformation resulting from cumulative movement of dislocations involves cracking and reformation of interatomic carbon bonds, contributing to the Raman D-peak. The characteristic nature of dislocation motion in specific directions and planes provides deformation of components. The existing dislocations and defects, crystal boundaries, cracks, and pores in the structure are important in initiating and propagating deformation and a potential reason for a dramatic increase in the number of dislocations and growth of preexisting cracks.

Experimental

Materials and Compression Test

A distinct laminar structure of graphite composed of a two-dimensional (2D) material known as graphene. The layered structure is constituted of basal planes where strong sp2-hybridized carbon atoms form hexagons in a honeycomb structure. The basal layers are held together through weak interlayer dispersion forces. The weak interlayer forces allow the crystallographic graphitic planes to adiabatic shear over each other, promoting the crystallographic defects in the bulk of crystals while maintaining the sp2 connectivity. Samples of graphite grade that are suitable for nuclear energy applications were used for the present study.

Quasistatic compression tests were conducted using a 5KN Deben Micro tester (Deben UK Ltd.). A miniature compression stage specifically designed to test microcomponents and a real-time observation of compressed region of a test sample were used under micro-Raman microscopy's enclosure. Compression tests were performed at ambient temperature inside the Raman spectrometer enclosure using a controlled load cell by an external controlling unit through electronic cabling.

Raman Microscopy

Raman spectroscopy has been considered as an effective technique to nondestructively evaluate local internal stresses (4) and material structural changes in graphite (5). Moreover, any disorder in the spatial arrangement of sp2-hybridized carbons in hexagonal rings and the optical phonon dispersion of graphite provide information in the Raman spectra that could be used to derive failure property of a component (6).

Raman spectra of carbon and its derivatives are well documented in the literature. The sp2-bonded carbons exhibit symmetry allowed by the E2g first-order graphite (G) band at a wavenumber of 1580 cm-1 and a disorder-induced (D) A1g band at a wavenumber of 1350 cm-1. First-order Raman spectra are commonly used to characterize defect and disorder in graphite microstructure (7).

Micro-Raman spectroscopy was conducted using a Senterra Raman microscope (Bruker Optics, Inc.), with a 532-nm wavelength excitation laser in a confocal mode of operation at a spatial resolution of 0.8 µm.

Results and Discussion

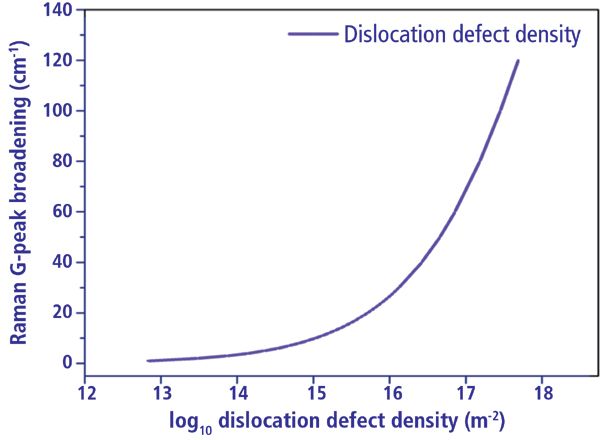

The strengthening of the Raman G-peak in stressed graphite is linked to the dislocation population in the structure over the scanned volume, which resulted in a strained crystallite region. To quantify the number of dislocations introduced in the structure, a physical model is developed and detailed methodology is provided in the literature (3). Figure 1 shows the calibration of Raman G-peak broadening as a function of dislocation population in graphite predicted using the model based on graphite physical properties (3,4).

Figure 1: Calibration of the Raman G-peak broadening as a function of dislocation density in graphite predicted from a physical model based on graphite material properties. Adapted with permission from reference 3.

The deformation strains concomitant with Raman G-peak shift (4) and their quantification is relatively straightforward for a known grain orientation, although the process is cumbersome for an arbitrary grain orientation. It may provide a wrong interpretation if grain orientation information is neglected. Therefore, it is essential before the measurement to know what the grain orientation in the component is. In the present work, we used a known grain orientation of polycrystalline graphite developed during the manufacturing process, marked as axial, radial, and azimuthal directions.

The graphite deformation behavior information derived from the Raman data is shown in Table I. The full width half maximum (FWHM) of the G-peak strengthened during loading conditions, and the Raman spectra have been analyzed to quantify the crystallite lateral size and dislocation density for each loading condition. The derived dislocation data at different stress values (Table I) show a nonlinear trend. Dislocations in the graphite microstructure in preexisting conditions (before the application of loading) was 7.5 x 1014 m-2. It is important to note that continuous increases in the dislocation population in the elastic region and further increases of dislocations and microcrack formation in the plastic deformation region are connected to stress increments (8).

Table I: Raman spectral analysis for graphite deformation behavior

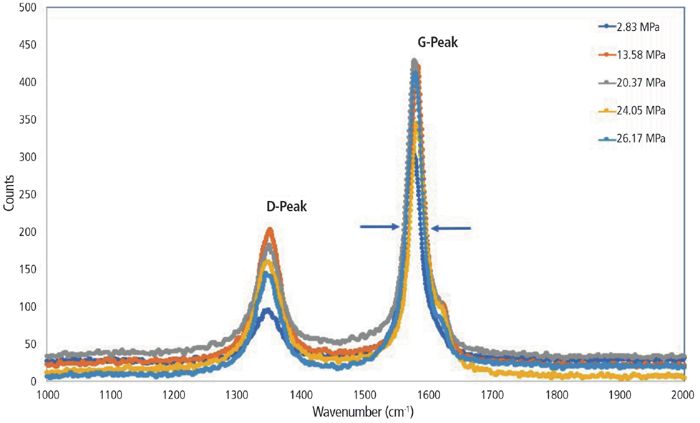

Figure 2 shows Raman spectra indicating D and G peaks with an increase in applied external stresses. The applied external stresses develop a strained crystallite region and are characterized by the changes in the Raman phonon frequencies as the carbon–carbon bonding lengths and angles alter as a material response to the straining effect.

Figure 2: Evolution of Raman spectrum under applied external stresses. Applied external stress increases the FWHMs of the Raman peaks (D and G) (shown by arrows), which are linked to dislocation density accumulation and generation of micro-cracking in the structure.

Quantification of dislocation density reveals that stresses imposed on the structure increases dislocation interaction and reach a sufficiently high value before failure (Table I). The calibration data shows that dislocations do not appear to saturate at high G-peak broadening (Figure 1), which indicates that during deformation a relative shearing of basal layers in an organized manner is a prominent process for generating dislocations. An increase in applied stress results in cumulative movement of dislocations, subsequently developing a plastic deformation in the structure. It is well known that slip directions and slip planes are important to know for a crystal system because edge dislocations move by slip and climb while screw dislocations can be moved by slip or cross-slip. The onset of deformation involves the motion of dislocations where they interact among themselves. Dislocation interaction is very complex depending on the number of slip planes available and for a hexagonal system only a limited number of slip planes exists. For example, in a hexagonal crystal system, the basal plane is the most common slip plane and prismatic or pyramidal planes are less common slip occurrence planes. In both slip planes, close packed directions are the slip directions.

Dislocations either annihilate or repel depending on their nature and subsequently affect the strain energy of accommodating material. A large fraction of dislocations do not annihilate completely because they are situated on neighboring slip planes, resulting in the formation of a row of vacancies or interstitial atoms. The hindrances to dislocation motion include crystallite boundaries, pores, cracks and change in the structure because of crystallographic orientation or phase change (binder to filler or vice-versa). The consequence of these hindrances of dislocation motion is the movement of dislocations at higher stresses. Dislocation can generate from preexisting dislocations, defects, disorder, crystallite boundaries, and surface irregularities. Because of the presence of these imperfections in abundance in graphite, the dislocation population dramatically increases during the onset of plastic deformation. Because further motion of dislocations requires an increase in stress, crossing the yield stress of material and reaching an ultimate strength before failure occurs. Therefore, a nonlinear relationship between Raman peaks and graphite microstructural information was observed. Graphite is a polycrystalline material and plastic deformation corresponds to distortion of the individual crystallites by means of slip. Further, note that in polycrystalline material crystallites may or may not be favorable for slip and each crystallite provides a mutual geometrical constraint on one other. Therefore, plastic deformation does not exist at low applied stresses and to initiate plastic deformation, a higher stress is required depending upon the orientation of crystallites. According to von Mises criterion, a minimum of five independent slip systems must be operative to maintain crystal boundary integrity and exhibit ductile behavior, which is not the case for most hexagonal crystal systems and graphite material. Therefore, polycrystalline graphite never shows ductile behavior, although small plastic deformation may be noticeable because of twinning or a favorable preferred orientation (9).

Understanding the graphite deformation behavior through the capability of the Raman technique provides a better insight about the deformation physical processes characterizing crack initiation, propagation, and subsequent failure. Raman spectral analysis shows an increase in the concentration of dislocation with a reduction in graphite crystal size (see Table I). The orientations of crystallites are mostly misaligned and thus, it is difficult for a dislocation moving on a common slip plane in one crystallite to pass over to a similar slip plane in another crystallite. In addition, the crystallites are separated by a thin noncrystalline region, which is the characteristic of a crystal boundary. Such atomic disorder at the boundary causes discontinuity in the slip planes. The smaller the crystallite size, the more frequent the pile up of dislocations is. Hence, dislocations are stopped by a crystal boundary, pile up against it, and show a rise in the ultimate stress.

Concluding Remarks

Raman microscopy is a reliable, fast, and sensitive technique for monitoring graphite deformation behavior and in the present research a practical application of the deformation behavior was discussed. This material information is of great importance from a point of fracture and in terms of gaining knowledge of the characteristic property of materials. The development in modern optics including diode lasers, improved detector capabilities, and fiber-optic coupling have led to a rapid increase in the use of the Raman technique, and it is gradually becoming a mature technique.

References

(1) T.R. Allen, K. Sridharan, L. Tan, W.E. Windes, J.I. Cole, D.C. Crawford, and G.S. Was, Nucl. Technol. 162(3), 342–357 (2008).

(2) B. Kelly, Physics of Graphite (Applied Science Publishers, London, 1981).

(3) R. Krishna, J. Wade, A.N. Jones, M. Lasithiotakis, P.M. Mummery, and B.J. Marsden, Carbon 124(Supplement C), 314–333 (2017).

(4) R. Krishna, A.N. Jones, R. Edge, and B.J. Marsden, Radiat. Phys. Chem. 111, 14–23 (2015).

(5) R. Krishna, T.J. Unsworth, and R. Edge, Materials Science and Materials Engineering (Elsevier, 2016).

(6) M.A. Pimenta, G. Dresselhaus, M.S. Dresselhaus, L.G. Cancado, A. Jorio, and R. Saito, Phys. Chem. Chem. Phys. 9(11), 1276–1290 (2007).

(7) A.C. Ferrari, Solid State Commun. 143(1), 47–57 (2007).

(8) T. Oku, T. Usui, M. Eto, and Y. Fukuda, Carbon 15(1), 3–8 (1977).

(9) J.F. Nye, Physical Properties of Crystals: Their Representation by Tensors and Matrices (Oxford University Press, Great Britain, 1985).

Ram Krishna and Paul M. Mummery are with the Nuclear Graphite Research Group, School of Mechanical, Aerospace & Civil Engineering, at The University of Manchester in Manchester, UK. Direct correspondence to: ram.krishna-2@manchester.ac.uk

LIBS Illuminates the Hidden Health Risks of Indoor Welding and Soldering

April 23rd 2025A new dual-spectroscopy approach reveals real-time pollution threats in indoor workspaces. Chinese researchers have pioneered the use of laser-induced breakdown spectroscopy (LIBS) and aerosol mass spectrometry to uncover and monitor harmful heavy metal and dust emissions from soldering and welding in real-time. These complementary tools offer a fast, accurate means to evaluate air quality threats in industrial and indoor environments—where people spend most of their time.

NIR Spectroscopy Explored as Sustainable Approach to Detecting Bovine Mastitis

April 23rd 2025A new study published in Applied Food Research demonstrates that near-infrared spectroscopy (NIRS) can effectively detect subclinical bovine mastitis in milk, offering a fast, non-invasive method to guide targeted antibiotic treatment and support sustainable dairy practices.

Smarter Sensors, Cleaner Earth Using AI and IoT for Pollution Monitoring

April 22nd 2025A global research team has detailed how smart sensors, artificial intelligence (AI), machine learning, and Internet of Things (IoT) technologies are transforming the detection and management of environmental pollutants. Their comprehensive review highlights how spectroscopy and sensor networks are now key tools in real-time pollution tracking.