Gulf Coast Conference: FTIR Spectroscopy for In-Service Lubricant Analysis

Andrew Schmitz, an application scientist at ThermoFisher Scientific, held a workshop at the Gulf Coast Conference in Galveston, Texas, focused on real-time lubricant analysis.

On October 10, Andrew Schmitz, an application scientist at ThermoFisher Scientific, held a workshop at the Gulf Coast Conference in Galveston, Texas, titled “Fourier Transform Infrared Spectroscopy (FTIR) spectroscopy for in-service lubricant analysis.”

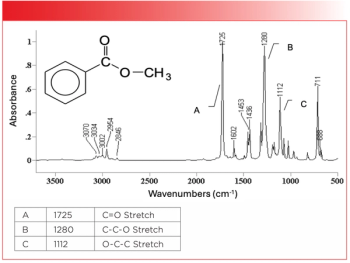

In-service lubricant analysis can act as predictive maintenance by helping machinery owners detect potential failures such as additive depletion, breakdown, and contamination. This prevents costly damages and requires fewer frequent lubricant changes. Infrared spectroscopy is used alongside this practice for its rapid nature, revealing detailed chemical information about lubricants and enabling users to identify the sources of potential mechanical failures.

Schmitz explained that infrared spectroscopy works best with oxidation, contaminants, and additives. Further, he added that FTIR is a standard ASTM International technique for monitoring molecular breakdown and lubricant contamination. There are also two different data handling approaches: direct spectral analysis and new oil reference subtraction.

Schmitz also provided multiple examples of different components analyzed with the system, such as soot, carbon oxidation products, and diesel fuel, and their infrared regions of interest, which varied in value and peak location. He also showed data of the company’s Affirma software working with different submethods, such as direct and differential trend analysis, which can vary in difficulty and accuracy.

Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.