High-Resolution NIR Analysis

Spectroscopy

New detector and optical bench options make it possible to configure near-infrared spectrometer setups for high-resolution applications such as laser and optical fiber characterization.

Near-infrared spectroscopy is a common analytical technique for chemistry and process control, where typical applications include identification of species and determination of water and fat content. In applications like those, absorbance peaks are often broad and optical resolution requirements of lesser concern than performance parameters such as low noise and high sensitivity.

Yet there also are number of NIR applications where optical resolution of <5.0 nm (FWHM) or better is critical. Characterization of laser lines — examples include solid state lasers at 1064 nm and at wavelengths from 1020–1050 nm, as well as semiconductor lasers with response in the 900–1800 nm range — often require even better optical resolution. Optical fiber characterization and determination of atomic emission lines are other high-resolution NIR applications.

Experimental Conditions

To test the optical resolution performance of our NIRQuest512-2.2 spectrometer, which has a Hamamatsu G9206-512W InGaAs-array detector and is responsive from 900–2200 nm, we measured the spectrum of a xenon source used for spectrometer wavelength calibration. The low-pressure gas-discharge source has a number of closely aligned emission lines in the region from ~820–2000 nm, making it a good choice for our experiment.

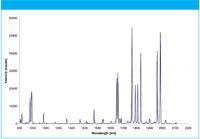

Figure 1: The closely aligned peaks of a xenon source used for spectrometer wavelength calibration can be distinguished with the high-resolution NIRQuest NIR spectrometer.

The NIRQuest512-2.2 was configured with a 100 lines/mm grating set to 900–2050 nm, with a 25 µm slit and gold-coated collimating and focusing mirrors for enhanced reflectivity. This is the standard configuration for the NIRQuest product line, which includes models for 900–1700 nm, 900–2050 nm, 900–2200 nm, and 900–2500 nm. Additional grating options and slit sizes are available for custom setups.

We used a 50 µm VIS-NIR optical fiber to collect signal from the xenon source. (For optimum results, we recommend the use of a 50 µm diameter or smaller optical fiber with all of our spectrometer wavelength calibration sources.) NIRQuest512-2.2 integration time was set to 350 ms and spectral averaging set to 5.

Results

The spectrum from the xenon calibration source illustrates that optical resolution of ~4.6 nm (FWHM) is possible with the NIRQuest512-2.2 in its standard configuration (Figure 1). What's more, even better optical resolution is possible in a NIRQuest512-2.2 configured with a grating that has a narrower spectral bandwidth. For example, a NIRQuest512-2.2 with a 600 l/mm grating set over a 100-nanometer bandwidth and configured with a 25 µm slit would yield optical resolution of <0.5 nm (FWHM). Resolution would improve even more with a 10 µm slit, but at the expense of throughput. For most laser applications, that's likely to be an acceptable trade-off.

Conclusions

New NIR detectors and optical bench options allow researchers to experience high optical resolution performance in the region from 900–2500 nm. This elevates the versatility of smaller footprint, more modular NIR spectrometers for applications previously thought to be out of reach.

Ocean Optics, Inc.

830 Douglas Ave., Dunedin, FL 34698

tel. (727) 733-2447; Fax (727) 733-3962

Website: www.oceanoptics.com;

Email: info@oceanoptics.com

Thermo Fisher Scientists Highlight the Latest Advances in Process Monitoring with Raman Spectroscopy

April 1st 2025In this exclusive Spectroscopy interview, John Richmond and Tom Dearing of Thermo Fisher Scientific discuss the company’s Raman technology and the latest trends for process monitoring across various applications.

A Seamless Trace Elemental Analysis Prescription for Quality Pharmaceuticals

March 31st 2025Quality assurance and quality control (QA/QC) are essential in pharmaceutical manufacturing to ensure compliance with standards like United States Pharmacopoeia <232> and ICH Q3D, as well as FDA regulations. Reliable and user-friendly testing solutions help QA/QC labs deliver precise trace elemental analyses while meeting throughput demands and data security requirements.