Application Note: Raman Spectroscopy for Reaction Monitoring

Sponsored Content

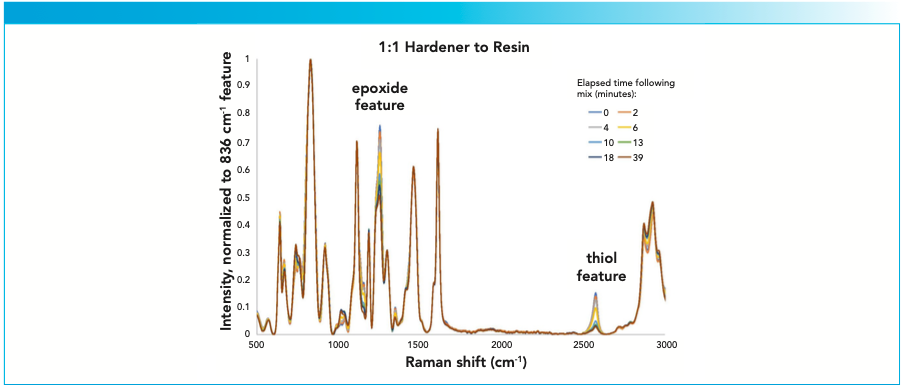

Raman spectroscopy monitors the kinetics and reaction completion of adhesive curing.

Epoxy resins are distinguished by durability, strong adhesion, chemical resistance, and other specialized properties, which are contingent upon proper mixing. In this application note, we monitor the curing process for a consumer-grade, two-part epoxy.

Experimental Setup

Devcon® 15 Minute Epoxy is comprised of bisphenol A diglycidyl ether resin and a polymercaptan/polyamine mixture. To monitor the curing process, we used an Ocean Insight QE Pro-Raman+ spectrometer with a 300 mW, 785 nm laser, and a Raman probe suspended at a fixed distance over the epoxy. Signals were acquired immediately upon mixing and in 2–3 min intervals thereafter.

Two samples of different proportions of resin and hardener were mixed, at the recommended ratio of 1:1 and at a 2:1 hardener-to-resin mixture, then monitored. The analytical focus was on the mixture’s epoxide and thiol features, which diminish upon curing.

Results

Raman bands corresponding to epoxide vibrational frequencies have been reported (1), with 1254 cm-1 assigned to be the breathing mode of the epoxide ring (Figure 1). The intensity of this peak is linearly dependent on the concentration of epoxide groups in the resin mixture; its change over time is interpreted as consumption of the free epoxide groups during epoxy vitrification.

Figure 1: Raman analysis of Devcon® 15 Minute Epoxy mixture, as a function of cure times (min).

Summary

Raman spectroscopy is useful in monitoring epoxy curing processes in real time and can be extended to other types of reactive processes.

Reference

(1) V. Křesálek, and H. Vašková, “Raman spectroscopy of epoxy resin crosslinking,” Recent Researches in Automatic Control, Conference Paper, May 2011.

Ocean Insight

3500 Quadrangle Blvd., Orlando, FL 32817

Tel. +1 (727) 733-2447

Website: OceanInsight.com