Fiber-Optic Bundles Create a World of Pure Imagination

Fiber optics have undoubtedly changed the world of spectroscopy and communications, existing as a foundation for countless platforms we encounter and work with each day. The use of multiple fibers in a bundle further expands these capabilities in several ways, some of which are obvious, and others that are more concealed and clever. Starting as a Central Intelligence Agency (CIA) encoding project under the guise of “gastroscope development,” fiber-optic bundles have evolved into many uses across industries. In this column, we explore this intriguing history and where it has led to, including the use of modern processing techniques that allow three-dimensional (3D) interpretations of traditionally two-dimensional (2D) readings.

When it comes to candy, would you rather have a single big chocolate bar, or a pack of M&M’s? Perhaps you may prefer a box of assorted chocolates, or you are really eccentric and prefer Skittles or some fruit-flavored sweet. Whatever your preference, any industry that exists long enough develops various form-factor and flavor options, and the world of fiber optics is no different. Over time, folks have moved away from the traditional chocolate bars and into more diverse offerings, and this article aims to touch on one such genre of fiber optics known as bundles.

Those without much direct experience with bundles may wonder how much there is to say about putting fibers next to each other, and those who work closely with bundle systems may wonder how a single article could capture any meaningful and complete point on the topic. Indeed, it is an area with a deep and intriguing history that has led it down multiple paths serving countless applications. In this column, we take a glance at some key highlights of the past, and some of the coolest implementations in the present and near future.

But first, back to the chocolate—who doesn’t love a classic chocolate bar? It has everything you love in a single, homogeneous, bulk form factor, and it satisfies chocoholic cravings at the most basic level. Standard fiber is very similar, giving you the ability to route light in a single, homogeneous, bulk form factor in a way that satisfies many applications just fine. Also, folks have been working with glass for a while, or at least since 2500 BC in Egypt and Mesopotamia, with Egyptians already carving glass heads by 1500 BC (1). Although proper fiber optics would come much later, even glass blowers back in the time of Jesus must have seen their glass rods guide light when putting them into a glowing furnace and looking at the ends.

But two things had to happen before glass fiber could become a common reality: One was a demonstration by British physicist John Tyndall in 1854 showing that light could travel through a curved stream of water (2), and the other was the Industrial Revolution, which made glass commonplace for windows and bottles (1). With the concept of single-core glass fiber established in the 1800s, but with no spectrometer to connect to, these fibers existed largely as a novelty during the Victorian Era, providing elegant decorations and demonstrations. But the eggheads were still tinkering, as they do, and they could see the flickers of potential these new “light pipes” had to offer.

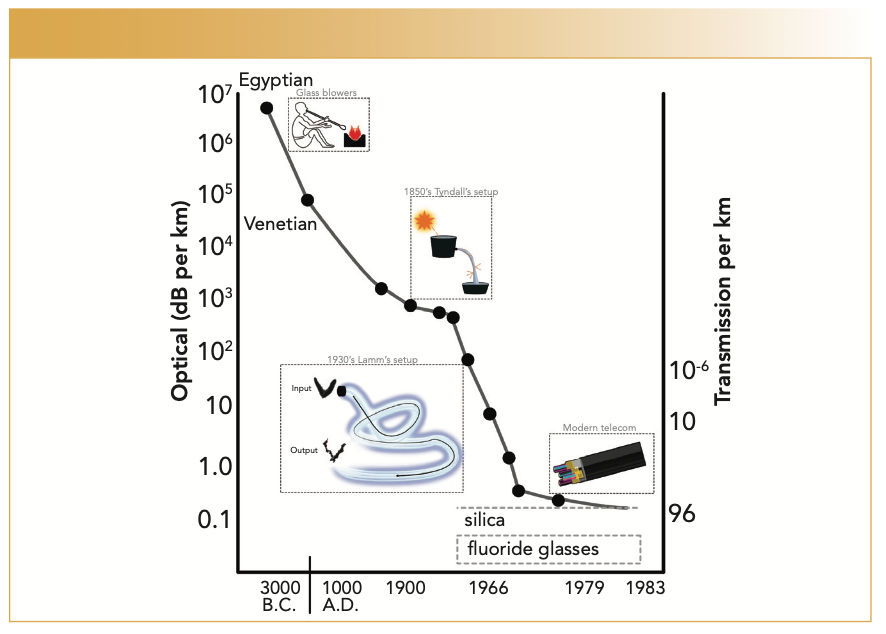

Fast forward to the 1900s, specifically Nazi Germany, and we find a fellow named Heinrich Lamm, who assembled an awkward and primitive bundle of glass fiber, and he used this to show how the ‘V’ image of a light bulb filament could be carried around a bend (1). Not terribly exciting today, but extremely revolutionary at the time! Unfortunately, Lamm’s Jewish background forced him to flee Germany and his work, which then sat idle for over a decade. A general timeline of some of these key events is shown in Figure 1, along with the gradual improvement of glass fiber transmission as the years went on.

FIGURE 1: Timeline of glass fiber quality development.

The end of World War II brought the beginning of the Cold War, and now information technologies were just as attractive as projectiles and explosives. Brian O’Brien had a clever idea for a fiber-bundle scrambler, which was immediately valuable to the CIA because the spy agency could use one half of the bundle to make ciphers that only the spy with the matching half could decode; the spy, in turn, could send messages back that only the spy masters could decode. Each pair of encoders would have a unique pattern, so loss of one scrambler would not break security for those using others. The CIA pushed this project forward under the guise of “gastroscopes,” which, indeed, had their own value for non-espionage purposes, but also had dramatically differ- ent requirements. Fibers in a gastroscope to be inserted down the esophagus need to be long, thin, and flexible, while fibers in a spy-device should be short, fat, and monolithic. Realizing this, a hungry MIT professor named Frederick Norton stole a clever idea from a Swiss roll cake. To be honest, there’s actually no proof of his relying on cake for the idea, but there’s also no proof against it, and the concept is quite similar. He would stack glass rods together, and then heat them to fuse and be twisted and stretched as desired; these could then be cut like a roll cake to create unique optical ciphers. Rather than cake, the technique he was more likely leaning on was the ancient craft of “millefiori” or “thousand flowers,” which is still used today in art and small objects like paperweights (1). Look up some examples, they are quite beautiful!

But as math usually ruins everyone’s day, it was determined that a mere 18-or-so intercepted images would be enough to crack the scrambling code, and the CIA eventually killed the cipher project to refocus (in honesty this time) on the gastroscopes they had said they were working on. The medical application evolved down its own path, but optical fiber bundles arguably had their first “real job” back in the 1960s reading the punchcards used in computers at the time. Early card readers used an array of 12 small and short-lived bulbs, with one to illuminate each row in a moving card. A fellow named Bob Potter at American Optical replaced this setup with a fiber bundle that collected light from one long-lived bulb and split the light into 12 smaller bundles, one for each hole. American Optical also developed 9–15-in bundles for NASA testing of the Saturn rocket boosters during the Apollo program, so these were finding some real-world usage (1).

We’ve gotten to the point in time where fiber bundles are a real thing, and people are figuring out they can be used to solve a wide range of problems. But let’s take a break from the history lesson, at least for the moment, and let’s talk about some of the key benefits fiber bundles offer us today in the world of spectroscopy and photonics:

- CoherenceOptions:

- “Mapped” bundles can be aligned to carry a coherent image.

- Patterned bundles can sync with some type of complex receiver.

- Randomized bundles do more than scramble images for the CIA, and can be useful to uniformly distribute multiple sources or perform some other type of photonic averaging or amplification.

- Fiber Flavor Options:

- Bundles allow you to mix and match various fiber types to create a diverse “box of chocolates.”

- Assemblies may include single- or multi-mode fiber, different numerical apertures, diameters, claddings, tapering, and any other aspect you would want to optimize. For example, a bundle may be created with a 50:50 randomized mix of UV-visible (UV-vis) and visible-near-infrared (vis-NIR) grade fiber, creating an extended broadband range with the durability and flexibility benefits described below.

- Durability and Flexibility:

- This is arguably the greatest benefit, as you can deploy bundle assemblies in very harsh and rugged environments with minimal risk of breakage or optical distortion. We will talk about this in greater detail since it can be such a blessing.

We’ve briefly touched on the concept of coherent bundles when looking at the history of Lamm’s work, and there is more to say about that shortly. But patterned bundles, which are meant more for data-based connectivity rather than image transmission, are a fulcrum in the world of communications. Like candy buttons where the right color is placed in the proper spot with its others, patterned bundles ensure signals are grouped as they should be. While Dorset, England is probably best known for its Jurassic Coast, its police force in 1975 was the first non-experimental entity to use a fiber-optic telecommunication link, and by the mid-1980s, Sprint had established the world’s first 100% fiber optic network (2). These fiber links require assemblies with consistent patterns and layouts, and the first telecommunications ribbon cables used 240 μm fiber in linear arrays of 6–12 held by mylar tape. A typical telephone line would have 12 ribbons of 12 fibers each, stacked on top of each other and surrounding a sheath embedded with strength supports in the center; a submarine version of this would essentially be the same thing with two layers of outer armor added (3). Today’s data servers use bespoke fiber-bundle patterns and connectors to relay the right information to the right place.

We all love and live for our communication technologies, but most readers are here for the real treat—that is, the theory behind it all. Thinking about the most basic multifiber assembly presents us with just two fibers side by side, and such multicore fibers can be split into two groups: Assemblies where fibers are designed for a controlled coupling of the guided modes between the cores, and assemblies where modes in the different cores are practically decoupled (4). Coupled assemblies may be similar to a KitKat bar, where the wafers are independent, yet connected, versus a Twix bar where each side is entirely decoupled; we will leave the mathematical proof behind the superiority of the left-side Twix for another article.

You can do some pretty cool things by arranging cores the right way. In a common twin-core fiber with two identical single-mode cores within the cladding, illuminating one core will equally excite two transversal modes in the fiber, one symmetrical and one asymmetrical. Energy is periodically transferred back and forth between cores, where the first core will be totally depleted of energy after some length, but this is now guided by the second core and will start to transfer back to the original core; this continues ad infinitum as light travels down the fiber. You can imagine how this would be useful in amplifiers and lasers, and the beat length, which is the fiber length necessary to complete one cycle of this, can be adjusted with core separation, geometry, refractive index, and wavelength (4).

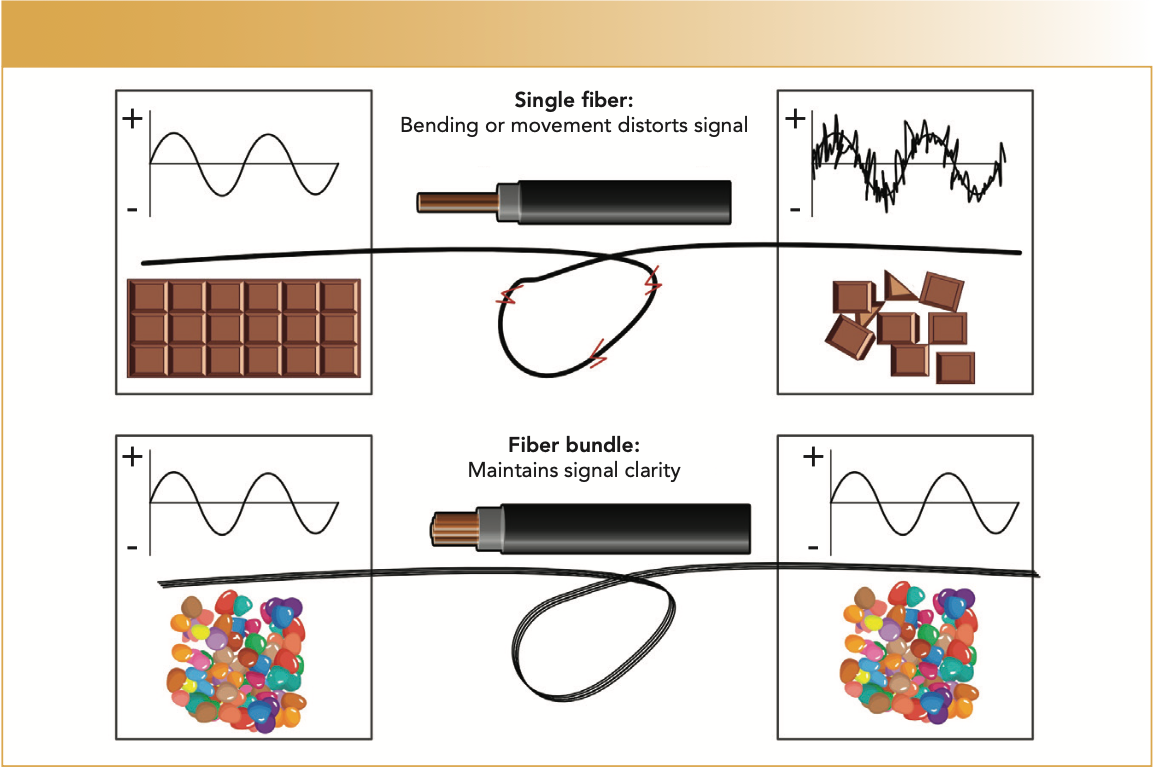

Perhaps the greatest benefit of fiber bundles comes from their inherent resistance to harsh environments and rough handling. There are actually two areas to touch on here: mechanical durability and optical stability. Starting with the former, have you ever had a chocolate bar in a backpack or other tight space, only to take it out and find it broken into several pieces? Note this does not happen with a pack of M&M’s due to the small size of the individual components. Similarly, fiber assemblies using single, large fibers are prone to breakage from overbending or mechanical shock, whereas fiber bundles using many small-diameter fibers can undergo extreme bends and hits without compromising the internal fibers...or at least saving the vast majority of the signal. Theory states that fiber bending will cause some high-order modes to hit the core-cladding interface at less than the critical angle and become lossy, while low-order modes should be unaffected (5). More complete predictions, however, state all modes will lose power at a bend—the wavefront propagation in a fiber will be compelled to move faster at the outer periphery of the bend than at the center of the fiber, and since it would be necessary to exceed the speed of light in the material to accomplish this feat, some loss must occur. Because all modes are represented in the wavefront, all lose power at a bend (5). Therefore, it is difficult to achieve requirements of high bandwidth and low sensitivity to bending with single large fiber, but bundles using small core diameters solve this because the bend ratio to the fiber radius is larger for the same absolute bending radius (4). Keep this in mind because it will come up shortly when we loop back to gastroscopes. Figure 2 provides a sketch of this metaphor between the form factors of chocolate and optical fiber.

FIGURE 2: Mechanical and signal stability benefits of fiber bundles.

Techniques such as two-step cladding can further improve bandwidth and bend immunity, and graded-index profiles, where fibers have a continually diminishing refractive index from the fiber axis to the cladding, can increase bandwidth by two to three orders of magnitude, when done right (4). The benefit to that technique is how it keeps the beams in the fiber center, but that’s another topic for another day.

A popular configuration for fiber used in common optical oxygen sensor systems is randomized multimode bundles, and an old demonstration we often showed in prepandemic trade show days was literally tying the fiber between the probe and electronics into a knot and then hitting the knot with a large rubber mallet. The demonstration showed how stable the optical signal remained despite dramatic bending and physical impact. Such resilience makes bundles instantly attractive for handheld probes, vehicle systems, industrial sensors, and other applications with high vibration and movement. If you’ve ever had a fiber-based absorbance setup such as using a standard 1-cm cuvette, you may have noticed your broadband spectrum became “wobbly” or “wavy” any time you touched the connecting patch fiber or even bumped the table. This is due to the mode-mixing effect seen in typical single-core, multimode fiber. By moving to a bundle, you will see this effect becomes muted or even disappears entirely because all of the mode-mixing “noise” from the individual fibers is now averaged across potentially hundreds of fibers in the bundle. Handheld dip probes, for example, see great improvement in optical stability and repeatability when using bundles to transmit light, at least in the UV-vis range. Going back to the chocolate bar versus M&M analogy, fiber bundles let the chocolate melt in your mouth and not in your hand...or rather, they let the optical signal make it to its intended destination, rather than degrade along the way. So, in terms of both external durability and internal photonic quality, bundles are essentially “the M&Ms of fiber optics.”

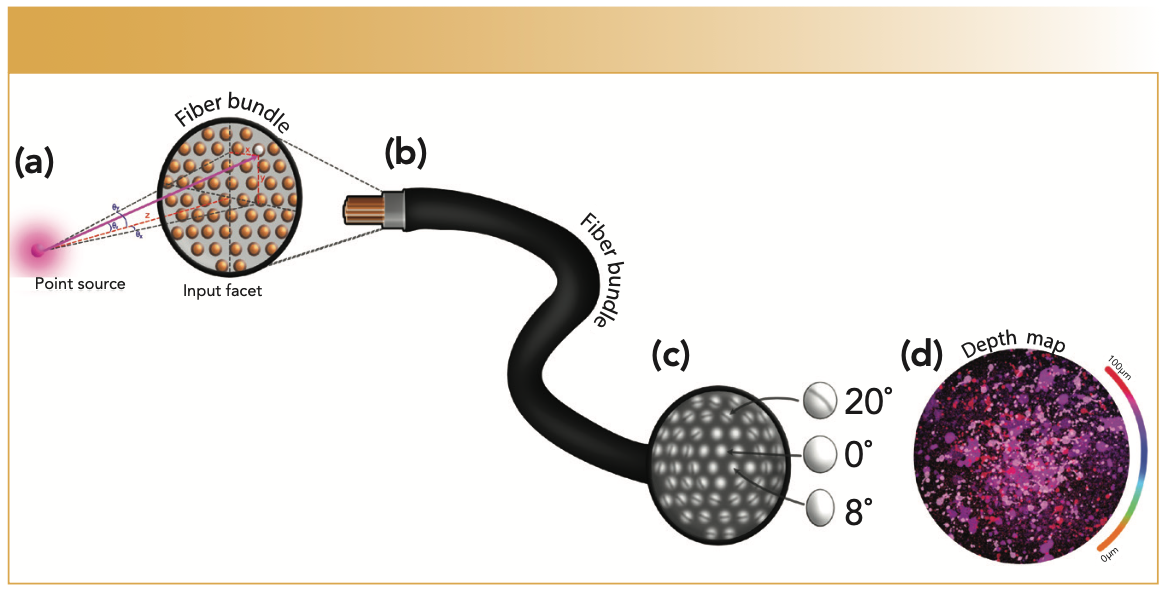

Let’s loop back to Lamm’s work on coherent image transfer back in the 1930s, but this time with a modern twist. The most important use of coherent bundles is the endoscope, which saves thousands of lives each year by seeing problems that would otherwise remain undetected. A standard endoscope can have over 10,000 fibers, which creates a 1-mm spot capable of 70 μm resolution (6). This is great for seeing and transmitting 2D images, but a group at the ARC Centre of Excellence for Nanoscale BioPhotonics at RMIT University in Melbourne has developed a clever method to extract 3D information from such images.

As you can imagine, the pixelation of an image coming out of a bundle is a function of how many fiber cores make up that image, and in normal operation this image is somewhat homogenized or “downsampled” to remove that pixelation effect, basically adding a slight blur to make it less choppy (7). This ends up eliminating any modal information that may be contained in the cores. What Orth and associates (7) have shown is that the intracore intensity structure of the output light carries information about the angular distribution of the input light, which can then be post-processed to map the original depth of the object; this is demonstrated in Figure 3 with a single fluorescent point source as the input, and also showing a mockup depth map of multiple point sources at various distances from the input facet.

FIGURE 3: Imaging a point source with an optical fiber bundle. (a) Schematic of point source placed at distance z from the input fiber. (b) A schematic of the fiber bundle showing input and output. (c) Example: raw image of output facet. (d) Processed depth map of multiple point sources in space.

Several paragraphs earlier, we were talking about high- and low-order modes experiencing loss at a bend, but how the small diameters used in bundles helps to minimize this. The technique proposed by Orth and colleagues is possible because the higher-order modes, which are preferentially excited at larger angles of incidence, carry more energy near the core-cladding interface than the low-order modes, such that light is effectively pushed to the edge of each core with increasing ray angle. They then use a process called digital aperture filtering to remove peripheral light for each core, creating a synthetically constricted numerical aperture. Using light field moment imaging (LMI), they can extract missing azimuthal information to calculate the average ray direction at a given point in the image. Orth’s paper obviously goes into much greater detail, and is a recommended read, but the key takeaway is that this now adds depth mapping to a traditional 2D image. This group used a bundle of 30,000 fibers with 2 μm diameter, and was able to achieve better than 10 μm depth accuracy with samples up to 80 μm away from the fiberface.

What would Heinrich Lamm think of this modern evolution of his inspiring first steps? What an amazing technological leap in less than a century to be roughly translating a large, distorted, 2D “V” shape into then generating 3D depth maps with 10 μm accuracy! We’ve tracked these human-led developments in the world of fiber bundles, and it’s time to bring our discussion to a close, but it’s also worth noting a fiber-bundle design developed by the world’s most prevalent inventor: nature. Remember the millefiori we talked about earlier, with the fused glass rods cut like a Swiss roll cake? There is a mineral called ulexite found mainly in Boron, California, that’s created through evaporation of mineral-rich lakes, and this naturally creates the same type of structure seen in the millefiori. These are sold in toy and rock shops as “TV stones,” because they translate the image from one face coherently to the other. Try to find one next time you’re in a novelty or rock shop, and maybe it will inspire your kids to have the next brilliant idea in fiber optic design and write the next chapter of the story.

References

(1) Hecht, J. City of Light; Oxford University Press, 1999.

(2) “History of Fiber Optics,” Timbercon. https://www.timbercon.com/resources/blog/history-of-fiber-optics/ (accessed 2023-1-13)

(3) Christian, N.; Passauer, L. “Fiber Optic Component Design, Fabrication, Testing, Operation, Reliability, and Maintainability,” Noyes Data Corporation, 1989.

(4) Mendez, A.; Morse, T. Specialty Optical Fibers Handbook; Academic Press, 2007.

(5) Briley, B. An Introduction to Fiber Optics System Design, North Holland, 1988.

(6) Ghatak, A.; Thyagarajan, K. Introduction to Fiber Optics; 1998.

(7) Orth, A.; Ploschner, M.; Wilson, E. R.; Maksymov, I. S.; Gibson, B. C. Optical Fiber Bundles: Ultra-Slim Light Field Imaging Probes. Sci. Adv. 2019, 5. DOI: 10.1126/sciadv.aav1555

Derek Guenther is a Senior Application Scientist at Ocean Insight. Direct correspondence to: derek.guenther@oceaninsight.com. ●

LIBS System Built on Microjoule High PRF Laser Identifies Aluminum Alloys for Recycling Potential

January 2nd 2024Differing grades of aluminum alloys have large differences in their composition, especially when it comes to trace elements, emphasizing the need for them to be evaluated for means of production, use, and recycling.