Failure Analysis of Packaging Materials

Application Notebook

Packaging materials function as a barrier to protect products from potential damage from premature aging that can occur from interacting with light, atmospheric water, oxygen, and so forth.

Packaging materials function as a barrier to protect products from potential damage from premature aging that can occur from interacting with light, atmospheric water, oxygen, and so forth. These packaging materials are often composed of several to many layers, where each layer that serves a specific purpose. Each layer is typically a polymeric film laminated to adjacent polymeric layers, but sometimes thin metal layers (foils) are also included. Other non-polymeric layers may also be included, such as adhesive seals or printed ink. Defects in such complex multilayered systems, like inclusions, can result in accelerated product degradation or even malfunction. Fourier transform infrared (FT-IR) microscopy is the best method for failure analysis and the reverse engineering of multilayer films. The IR spectra provide information about the chemical identity of not only the individual layers, but also any contaminants present.

Experimental Conditions

The LUMOS FT-IR microscope is an all-in-one solution with an integrated spectrometer, a high degree of automation, and a dedicated user interface. The innovative motorized attenuated total reflectance (ATR) crystal allows performing the complete measurement procedure fully automated including background and sample measurements. The dedicated OPUS software Wizard guides the user through the whole measurement procedure. For identification of unknown compounds, spectrum search and mixture analysis are applied using the functionality of the OPUS/SEARCH package. Chemical images of the spectral data are generated from univariate and multivariate analysis results.

Results

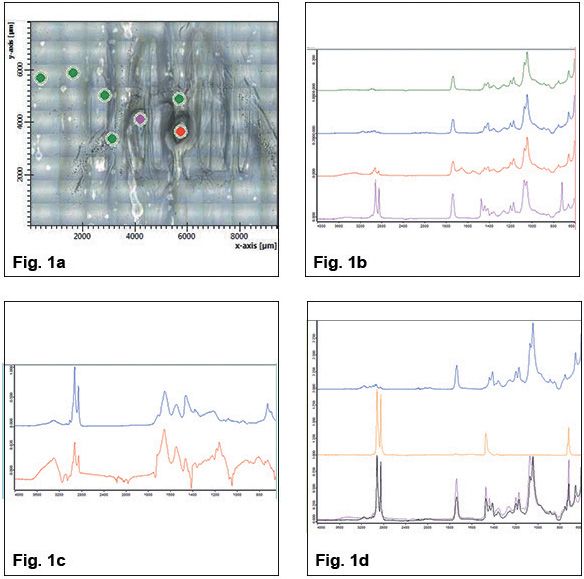

A transparent packaging film with included defects was analyzed. Measurement positions were selected to target the defects and other areas of interest on the intact film (Figure 1a). The automated data collection was performed using the ATR mode with an acquisition time of 20 s/spectrum and at a spectral resolution of 4 cm-1. The film was identified as polyvinylidene chloride acrylate copolymer by spectrum search in the comprehensive ATR COMPLETE™ library (Figure 1b). The spectra collected from the defective area (red label) also showed the spectral signature of the basic film, but additional bands were also evident. The search function in OPUS automatically removed the film spectrum yielding the spectrum from the unknown contaminant. If the result of a spectrum search accounts for some, but not all of the bands of the query spectrum an automatic subtraction of the reference library spectrum and search of the residual spectrum is be performed with a single mouse click. In this case, the red labeled spot clearly showed that the additional component was a polyamide resin (Figure 1c). The second contaminant (labeled pink) was determined to be polyethylene (Figure 1d) after subtraction of the base film spectrum.

Figure 1a: Visual microscopic image of a film with defects. Measurement positions are indicated by the colored dots.

Figure 1b: Infrared spectra of the film (green), the polyvinylidene chloride acrylate copolymer reference (blue), and the defects (red and pink, respectively).

Figure 1c: The reference polyamide resin spectrum (blue) and the film spectrum minus the polyvinylidene chloride acrylate copolymer (red) spectrum.

Figure 1d: The reference polyvinylidene chloride acrylate copolymer spectrum (blue), reference polyethylene spectrum (orange), and original film spectrum (pink) with the constructed spectrum of the polyvinylidene chloride acrylate copolymer spectrum plus the polyethylene spectrum (black).

Conclusions

Small multicomponent objects can be readily analyzed using IR microscopy. The analysis of these objects is greatly facilitated by the used of mixture analysis software.

Bruker Optics

19 Fortune Drive, Manning Park, Billerica, MA 01821

tel. (978) 439-9899

Website: www.bruker.com/optics

Best of the Week: AI and IoT for Pollution Monitoring, High Speed Laser MS

April 25th 2025Top articles published this week include a preview of our upcoming content series for National Space Day, a news story about air quality monitoring, and an announcement from Metrohm about their new Midwest office.

LIBS Illuminates the Hidden Health Risks of Indoor Welding and Soldering

April 23rd 2025A new dual-spectroscopy approach reveals real-time pollution threats in indoor workspaces. Chinese researchers have pioneered the use of laser-induced breakdown spectroscopy (LIBS) and aerosol mass spectrometry to uncover and monitor harmful heavy metal and dust emissions from soldering and welding in real-time. These complementary tools offer a fast, accurate means to evaluate air quality threats in industrial and indoor environments—where people spend most of their time.