Think Small: Low-Cost Optical Spectral Measurements for Chemical Sensing

Guest author John Coates discusses a miniature spectral measurement system that operates as a full spectrum analyzer, a colorimeter, or a multichannel photometer in the form of a spectral engine.

The term spectral engine is not new and is normally intended to indicate the integration of optics and electronics to form a single measurement package. In the system described in this column, the term is extended to include the close-coupling of the measurement system to the sample via nonimaging optics.

John P. Coates

This column focuses on the spectral engine concept and its role as an integrated component into continuous in-line/on-line measurement systems. One obvious mode of integration is the combination of the spectral sensor within a process analytical measurement system, and this is discussed in terms of the New Sample Sensing Initiative (NeSSI) miniaturized sampling systems, pioneered by the Center for Process Analytical Chemistry (CPAC), which is the industry–academia consortium based at the University of Washington, Seattle. Other forms of integration can include combinations with other small-scale sampling systems and microfluidic devices. Examples of applications are provided ranging from water quality measurements to the compositional measurements of organic sample streams.

Emil W. Ciurczak

In 2000, I discussed the concept of a small-scale "microspectrometer" based upon the integration of a spectrally separating optical filter, known as a linear varible filter (LVF), with a photodiode array (1). This device, known as the microPac, was developed and introduced by Optical Coatings Laboratories, Inc. (OCLI), now a division of JDS Uniphase (Santa Rosa, California). These systems featured visible and near-infrared (NIR) filter devices optically coupled to a commercial silicon photodiode array. At that time, the device was offered as a tool for instrument developers. For some, one issue was that there were a number of miniaturized spectrometer systems on the market that offered good performance at competitive prices. When viewed as an instrument platform, the microPac did not seem to offer any advantage over the existing microspectrometers, primarily because of cost and size issues.

The role of LVF devices, also termed variable filter array (VFA) devices, has been pioneered by Wilks Enterprises (South Norwalk, Connecticut) (2) for infrared spectroscopy applications. Wilks has always taken the position that high resolution is not necessary for dedicated analyses and has demonstrated this with the VFA analyzer systems. The Wilks VFA instruments operate with a typical spectral resolution in the range 40–50 cm-1 . Wilks has contended that most analyses can be performed at low resolution and that optical filters are adequate for such measurements. The microPac microspectrometer was similar in concept but had its focus on the visible and NIR and provided a spectral resolution (based upon spectral bandpass) in the range of 4–8 nm. Likewise, adequate measurements could be made in the visible and NIR with this degree of spectral resolution.

When the original microPac was introduced, it was recognized that it should be viewed as something different than a traditional instrument; the biggest opportunity for this type of integrated device was for spectral sensing. Spectral sensing means a component that can be integrated into a measurement system for monitoring chemical composition, rather than a standalone instrument. In the broadest sense, spectral sensing can be performed by instruments; however, instruments are not necessarily convenient or cost effective for true sensing applications. In an ideal world, spectral sensing should be performed by small, low-cost dedicated devices that are fully integrated with sample handling, data acquisition, and data handling. Such systems ideally are compact, maybe being no more than 1–2 in. wide and a few inches in length. They should be in a format that can be introduced into a process without major impact on the operation of the process. Note that the word "process" can be taken in the broadest sense and can include traditional industrial production processes, but it also can include environmental, biological (medical), and consumer-related processes such as water condition or quality monitoring.

The microPac microspectrometer did lend itself to that kind of thinking insofar as it was compact and was packaged with all of the electronics necessary to make it self-sufficient. However, it was not a fully integrated device and it did not include an energy–light source or a sampling interface. Furthermore, it was not immediately adaptable to specific applications. This article will discuss the development of the next-generation spectral sensor, an evolution in optoelectronic packaging and a full integration with electronics and sample interface. The device, termed a micro spectral sensor, from micro Spectral Sensors (Wilton, Maine), features a spectral engine that is designed to operate within a variety of platforms, the most important being handheld versions, with their own integrated sample dispensing, and on-line versions, which are designed for integration directly into a sample stream via a dedicated sampling system.

The focus for this current article, by way of example, is an on-line version, configured to operate with the NeSSI (ISAS standard SP76) small-scale modular sampling system platform. A follow-up column early in 2007 will describe the unique handheld versions of the system. With such a system it is possible to configure the spectral sensor for highly targeted applications. However, with on-board "smarts," the overall system can provide multiple analyses from a single device by selection of a suitable spectral range and appropriate reagents (if required).

The standard version of the micro spectral sensing system is based upon a full spectrum version, which provides spectral data ranging from the long-wave UV, through the visible, and into the NIR. The spectral engine concept has been designed to allow for highly targeted applications in which colorimetric or dedicated multiwavelength sensing is accommodated. The colorimeter version is a basic configuration and provides an output based on a color assessment from a standard RGB system. The third version, which is effectively a multichannel photometer, is a hybrid, which combines attributes of both the full spectral analyzer and the RGB system. The spectral range in this case is not fixed and is defined by the combination of sources and wavelength selection devices used to make up the system. As designed, such a system can cover the UV–Vis and NIR wavelength ranges.

The Microspectral Sensing Concept

When discussing microspectral sensors it is necessary to put the terms microspectrometer, spectral sensors, and spectral engines into concept. In the end, the meaning is often in the eyes of the beholder and is very context or application dependent.

With regard to the general term microspectrometer, there are a large number of "spectrometers" or "spectrographs" that have been miniaturized and are sold in "small boxes." In the strictest sense of the word, physically, these are true spectrometers. The term microspectrometer has not always done justice to the potential of these instruments because, to "purists," they are not perceived to be real spectrometers. However, in reality, most commercial microspectrometers have the performance capabilities of conventional instruments. Current commercial microspectrometers are available at prices ranging from $2000 and upward. Because of their size, microspectrometers have enabled a multitude of new applications and a broad range of final product formats. These commercial devices can provide high spectral resolution, down to subnanometer resolution, matching the performance of conventional, large high-resolution spectrographs. Commercial microspectrometers can handle most applications in atomic and molecular spectroscopy.

The microspectral sensor device discussed in this article is something very different from a traditional microspectrometer. The device is not intended to replace the role of microspectrometers; instead, it is intended to either complement microspectrometers or to fill roles not currently served by these instruments. Certainly, for nonchallenging applications, a microspectral sensor might provide a comparable function to a microspectrometer. However, it is important to identify the application and to understand the relative role of a sensing system versus that of an analytical device, such as a spectrometer. The spectral sensor described here has a nominal spectral resolution (based upon spectral bandwidth and digital sampling) of 8 nm. Many applications can be served by simply monitoring a change in status or composition. For such applications, all a sensor needs to do is identify a change within an environment, or a delta function.

The key word to describe the microspectral sensing concept is integration and the formation of a spectral engine. In a traditional spectrometer or photometer, it is normal to consider the instrument separately from the sample, and often even the data handling. In a microspectral sensing system, sample and sensor are close-coupled to provide what one can describe as an efficient management of photons. Most instruments require either internal or external optics to direct the radiation–light from the source to the sample and from the sample back to the detector of the instrument. These can range from traditional mirror–lens optics to optical fibers, or combinations of both. No ancillary optics are required in the micro spectral sensing concept; instead, the energy is channeled via transparent guides into the measurement chamber and is returned after interaction with the sample via a retroreflective system through a matching guide to the detection system. The term detection system is used somewhat generically because, in fact, the detector is also the spectral measurement system. As mentioned earlier, different detection options are involved, depending upon the application and the wavelength region of interest.

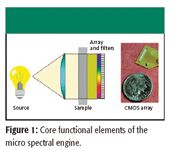

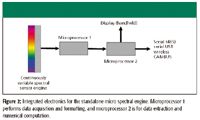

Currently, configurations covering the visible and NIR spectral regions are in use. Figure 1 is a generic representation of the key components of a microspectral measurement system (1). While these are the functional elements (source, sample, and detection system), they are not the full implementation of a spectral engine. The separation here between an instrument and a spectral sensor is the ability to control the entire process of data logging and spectral data extraction onboard the device by dedicated electronics (Figure 2). In such a system, the raw signal from the spectrally configured detector is acquired and conditioned into a spectral measurement space based on wavelength and spectral intensity (absolute or relative).

Figure 1

Multiple microprocessors can be used to convert the conditioned spectral signal into analytically relevant results such as analyte concentration or overall chemical composition. The conversions can range from simple linear equations, such as a basic implementation of Beer–Lambert, to a multivariate, multiequation solution based on chemometrics. The final component of the electronics of such a spectral engine is the communication of the resultant analytical data, which can range from an onboard visual display to hardwired (serial or bus oriented) or wireless external communications.

Figure 2

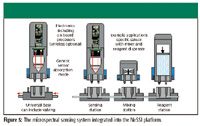

As indicated earlier, the overall spectral engine, by definition, includes the sample interface. An example, in generic form, is presented in Figure 3. In this generic representation, the sample is accommodated within an optical chamber or a light interaction cavity. This approach can be incorporated within a number of different platforms ranging from a portable handheld device to an integrated in-line/on-line process monitoring system. It is this latter approach that will be discussed in further detail.

Figure 3

In-Line/On-Line Spectral Sensing

For some time now, there has been a focus in the process analytical community on the scaling down and miniaturization of sample systems used to interface process lines to instrumentation. One of the most visible and most concerted efforts has been the development of the NeSSI standard. Several manufacturers have developed products, in the form of packaged components and integrated systems, based upon the ISAS standard SP76 sampling platform.

Figure 4 shows an early manifestation of NeSSI and this standard, where components are built upon a common base with a standard footprint forming what is known as the standard NeSSI substrate. NeSSI is now being accepted by many industrial end-users as a standardized approach to the interfacing of conventional analyzer systems to process lines. The expansion plans for NeSSI include a phase where the analyzer systems themselves are integrated into the backbone of the NeSSI substrate (NeSSI 3). To a traditional observer, this might be a leap in faith when one views traditional process analyzers. However, in the context of the microspectral sensing concept and the format discussed previously, it is easy to appreciate that NeSSI can become a process analyzer in which sample conditioning and measurement are performed by a single entity.

Figure 4

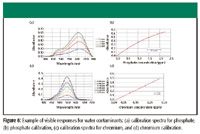

With this in mind, one also can look at a number of standard methods of analysis and implement these within a single package by combining the spectral sensor with sample conditioning steps that include the interaction with standard chemical reagents, indicated, in concept, by Figure 5. This approach can bring on-line many standard methods of analysis within a single analytical platform because of the ability to program the sensor for different methods and reagent combinations. A classical example here is the analysis, by spectral or colorimetric methods, of water for quality and potential contamination. Figure 6 provides data obtained directly from a prototype microspectral sensor system for the analysis of phosphate and chromium(VI) in water. These two are important contaminants and are critical analytes for water quality testing from natural water resources. They are just two of many examples of water quality measurements possible with integrated sampling–spectral sensor measurement systems. Note that a NeSSI platform is used to set the stage for the concept of an integrated measurement system. However, for dedicated applications such as water quality monitoring, the integration of the spectral sensor with a custom-designed reagent dosing unit (for multiple reagents) can provide an optimized measurement package.

Figure 5

Many analyses do not require special chemical reagents to meet the requirements of a particular measurement. Many compounds are naturally colored, and so measurements can be made directly on materials containing such substances. Also, many additional analyses can be performed in the NIR. The short-wave NIR region has been used for many industrial measurements, with dedicated process analyzers, for chemical and petrochemical and for food and beverage applications. The microspectral sensor system is available in an NIR version, which can be used on its own or integrated into a NeSSI type of sampling system for on-line measurements of chemical composition and chemical–physical properties. Some examples are provided in Figures 7 and 8, where microspectral sensing can be used to monitor changes in composition, or to measure specific properties, such as alcohol content of fermentation products.

Figure 6

Conclusion and Things to Come

This article has introduced a new concept of spectral measurement and a new approach to the miniaturization of spectrometers. As indicated, the devices are described best as spectral sensors rather than spectrometers. They are discussed in terms of a core spectral engine that can be integrated readily into a number of different platforms ranging from simple handheld devices to on-line monitoring systems. These devices can be used for on-line monitoring for traditional and nontraditional applications.

Figure 7

The microspectral sensor concept not only provides miniaturization, where the critical components can be unobtrusively incorporated into a measurement system, but it also provides a cost reduction to the point where spectral measurements can be incorporated into everyday applications. These can range from applications at work to those at home, in industry, in the environment, in public places, and in places of medical care. Many of these are part of a long-term goal, and today they are one step closer to becoming reality.

Figure 8

John P. Coates is principal consultant for Coates Consulting and is a partner in several companies that design optical/spectral sensing systems.

Emil W. Ciurczak is chief technical officer at Cadrai Technology Group (Bel Air, MD). He can be reached via email at: emil@ciurczak.com

References

(1) J.P. Coates, Spectroscopy 15(12), 21–27 (2000).

(2) P. Wilks, Jr., Spectroscopy 20(12), 101–103 (2005).

A Proposal for the Origin of the Near-Ubiquitous Fluorescence in Raman Spectra

February 14th 2025In this column, I describe what I believe may be the origin of this fluorescence emission and support my conjecture with some measurements of polycyclic aromatic hydrocarbons (PAHs). Understanding the origin of these interfering backgrounds may enable you to design experiments with less interference, avoid the laser illuminations that make things worse, or both.

Raman Microscopy for Characterizing Defects in SiC

January 2nd 2025Because there is a different Raman signature for each of the polymorphs as well as the contaminants, Raman microscopy is an ideal tool for analyzing the structure of these materials as well as identifying possible contaminants that would also interfere with performance.