Low-Concentration Melamine Detection with the IdentifyIR Diamond ATR Spectrometer

Detection of contaminants in consumer products is a critical public-safety need. One of the challenges of this type of detection is that the contaminant chosen is frequently designed to "fool" the routine product-safety testing performed. For example, melamine as the adulterant of choice to lower the cost of milk is because melamine contains nitrogen molecules.

Background

Detection of contaminants in consumer products is a critical public-safety need. One of the challenges of this type of detection is that the contaminant chosen is frequently designed to "fool" the routine product-safety testing performed. For example, melamine as the adulterant of choice to lower the cost of milk is because melamine contains nitrogen molecules. During protein assay, the type of quality-control testing typically performed on milk products, these nitrogen molecules allow the adulterated product to behave like the authentic product. The infrared spectrum of melamine, though, has absorption bands that are distinctly different from absorption bands found in dairy products. This makes it possible to use infrared spectroscopy in the form of the IdentifyIR® to detect melamine at relatively low concentrations in dairy and non-dairy powder mixtures. The IdentifyIR is also ideal for this analysis because it is easy to use, requires minimal analyst training and does not require extraction of the melamine from the powder matrix prior to analysis.

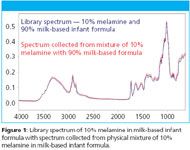

Figure 1

Testing Summary

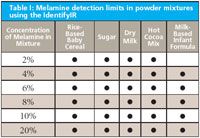

The IdentifyIR Infrared Spectrometer was used to quickly, easily and accurately detect low concentrations of melamine in dairy and non-dairy powder mixtures. In this study, melamine was detected at 2% concentration in sugar, hot cocoa mix, rice-based baby cereal and non-fat dry milk. It was detected at 4% concentration in milk-based infant formula. While the matrices within which the melamine is dispersed can slightly alter the limit of detection, this data shows that the use of the IdentifyIR for low-level detection of melamine in dairy and non-dairy powder mixtures is universal.

Experimental Design

Physical mixtures of each powder with melamine were prepared in the melamine concentration range between 2% and 20% (w/w). Seven infrared spectra were collected from each of these powder mixtures and the average spectrum was calculated. The average spectrum was then searched against a library prepared for the specified powder mixture. These individualized libraries were comprised of linear spectral combinations of pure melamine and pure food powder in 5% increments between 0 and 100%. A first-derivative correlation was used as the comparison algorithm. Analysis time to determine the presence/absence of melamine for each sample from start to finish was between five and ten minutes with no pre-analysis extraction required. Whole mixtures were analyzed.

RESULTS

A summary of data and results collected from all the samples analyzed are displayed within Table I. The limit of detection determined varies depending upon the type of powder mixture analyzed, but this data shows that once the limit of detection is established for a powder mixture, the IdentifyIR can be used to reliably detect melamine at concentrations at this limit and higher.

Table I: Melamine detection limits in powder mixtures using the IdentifyIR

Conclusion

The individualizing characteristic of an infrared spectrum coupled with the ability to analyze melamine without extraction prior to analysis makes the use of infrared spectroscopy ideal for detecting melamine in powder mixtures. The ability to use the IdentifyIR to collect an infrared spectrum in seconds with little-to-no analyst training makes it the ideal tool for analysis and detection of melamine and other adulterants in dairy and non-dairy powder mixtures.

Smiths Detection

3202 Regal Drive, Alcoa, TN 37701

Tel. (203) 207-9700, Fax (203) 207-9780

Thermo Fisher Scientists Highlight the Latest Advances in Process Monitoring with Raman Spectroscopy

April 1st 2025In this exclusive Spectroscopy interview, John Richmond and Tom Dearing of Thermo Fisher Scientific discuss the company’s Raman technology and the latest trends for process monitoring across various applications.

A Seamless Trace Elemental Analysis Prescription for Quality Pharmaceuticals

March 31st 2025Quality assurance and quality control (QA/QC) are essential in pharmaceutical manufacturing to ensure compliance with standards like United States Pharmacopoeia <232> and ICH Q3D, as well as FDA regulations. Reliable and user-friendly testing solutions help QA/QC labs deliver precise trace elemental analyses while meeting throughput demands and data security requirements.