Monitoring and Control of a Semi-Batch Polymerization with Raman Spectroscopy

Semi-batch reactions offer several advantages over traditional batch reactions, such as greater selectivity of products, gradual addition of reactants for better process control, and the ability to isolate product as it is formed.

Polymerizations are often done in semi-batch mode because it offers the ability to carefully control the composition of the product in order to create high-performance materials with fine-tuned custom properties.

However, one significant challenge of semi-batch reactions is that the concentrations of the reactants constantly change, in both relative and absolute senses. If uncontrolled, this variation in the concentrations of reactants can easily result in unwanted properties in the product. So, this reaction mode requires continuous real-time monitoring of the concentrations of the reactants. Simply adding the reactants in the correct ratios is insufficient.

Additionally, batch-to-batch consistency is essential for high-performance materials with finely tailored properties. In many manufacturing plants, the same process equipment must be capable of producing a wide variety of high-performance materials, so the process-control method must be both precise and flexible.

Raman spectroscopy offers several advantages for real-time process monitoring of semi-batch polymerizations. It can identify bands specific to particular functional groups, such as the vinyl and alkyl moieties common to polymerization monomers, and it offers both easy sample interfacing and fiber optic coupling of the probe to the base unit for flexible placement of the base unit relative to the process line.

Experimental

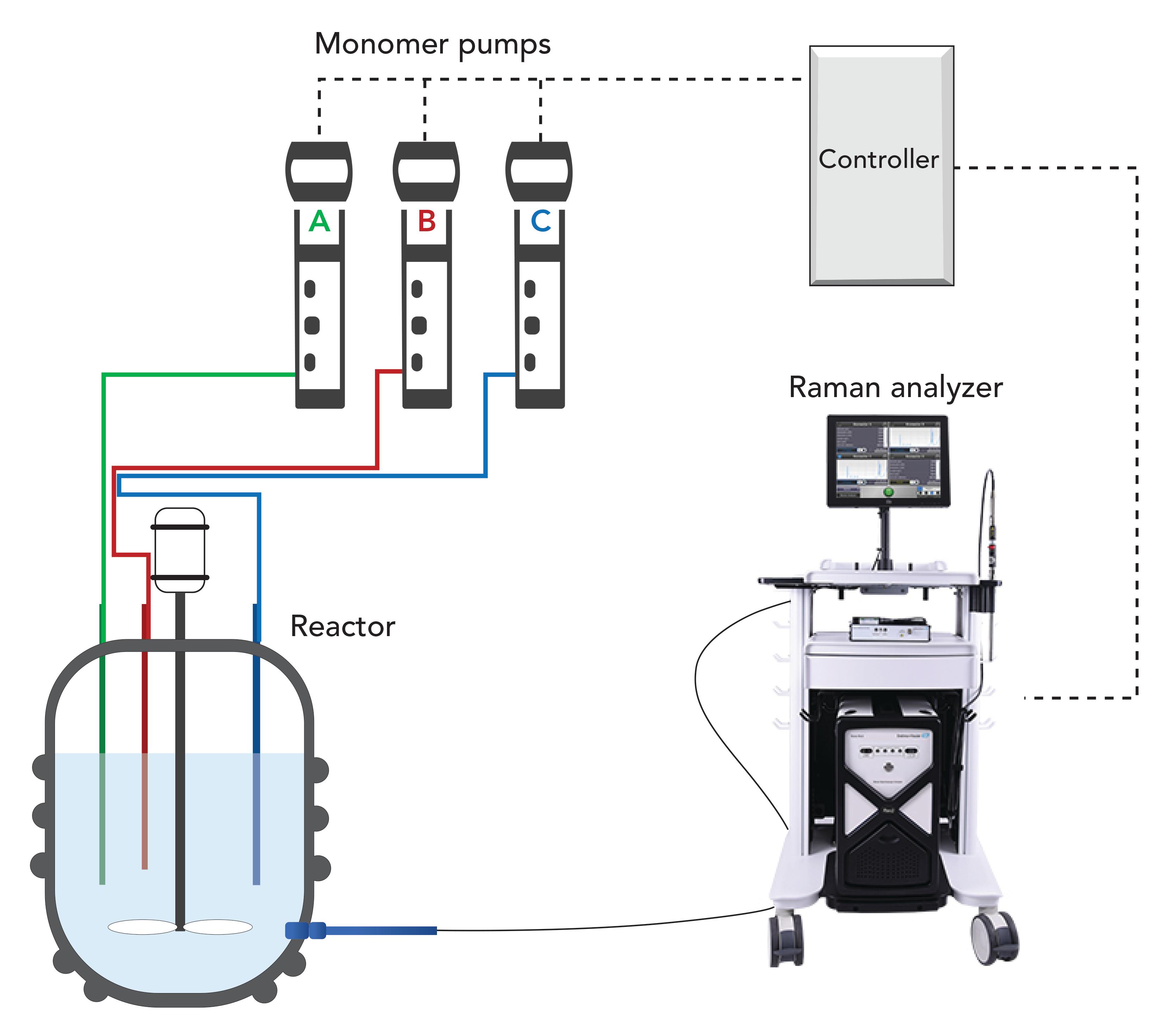

In this experiment, a semi-batch polymerization reaction was carried out using three proprietary monomers, designated monomers A, B, and C. A schematic of the system is shown in Figure 1.

Figure 1: Schematic diagram of process control system for semi-batch polymerization

A Raman analyzer was used to deliver and collect 785 nm near-infrared radiation from a laser. A non-contact optic was used to perform the analysis through a pressure- and temperature-rated sapphire viewport in the wall of the reactor. Each sample acquisition consisted of 60 s of illumination of the reactor contents using 125 mW of laser radiation, followed by a 20 s pause. Five to seven data points from each monomer were used to generate quantitative Raman data for real-time process control.

In this reaction, a vinyl functional group in each of the three monomers changes to an alkyl group during the polymerization. Raman spectroscopy is sensitive to this, whereas traditional infrared spectroscopy is much less so. Chemometric modeling in this case was based on the Raman signal for the vinyl region in all monomers, the C–H wag in monomers A and B, and the lactone region in monomer C.

Conclusion

Raman spectroscopy was demonstrated to be a simple, accurate, and effective method of process analysis for the purpose of real-time monitoring and control of a semi-batch polymerization. Raman data were able to be used for real-time feedback control of the process to maintain ideal process conditions in a closed-loop reaction system and to produce a highly consistent product between batches, ensuring consistent quality of sensitive high-performance materials.

Reference

J. Müller et al. Process Analytical Technology, 9–10 (2006).

Endress + Hauser USA

2350 Endress Place, Greenwood, IN 46143

Tel. (888) 363-7377

www.endress.com

Hole Extraction in Perovskite Solar Cells

December 16th 2024Efficient charge extraction is crucial for high-efficiency solar cells. Electron and hole extraction layers optimize cell performance. PL spectroscopy, proportional to carrier number, is ideal for comparing extraction layer efficiency.