Preparation of Pharmaceutical Samples for Elemental Impurities Analysis: Some Potential Approaches

The use of atomic spectroscopy techniques and sample preparation procedures is something that is not as routine in the pharmaceutical industry as are chromatography-based techniques and sample preparation procedures. With new requirements being implemented regarding elemental impurities by the United States Pharmacopoeia (USP) and International Conference on Harmonization (ICH), analysts in the pharmaceutical industry are, in many cases, working to determine how best to analyze their samples. Sample preparation techniques that can be used for pharmaceutical samples are the same ones that have been used by other industries for many years. This paper will provide a brief overview of potential techniques.

The use of atomic spectroscopy techniques and sample preparation procedures is something that is not as routine in the pharmaceutical industry as chromatography-based techniques and sample preparation procedures are. With new requirements being implemented regarding elemental impurities by the United States Pharmacopeia (USP) and International Conference on Harmonization (ICH), analysts in the pharmaceutical industry are, in many cases, working to determine how best to analyze their samples. Sample preparation techniques that can be used for pharmaceutical samples are the same ones that have been used by other industries for many years. This article provides a brief overview of potential techniques.

As the pharmaceutical industry prepares to implement the International Conference on Harmonization (ICH) guideline, ICH Q3D “Elemental Impurities” (1) and United States Pharmacopeia (USP) chapter <232> “Elemental Impurities-Limits” (2), there will be a need for laboratories to perform analyses of drug products, excipients, and active pharmaceutical ingredients (APIs) using USP <233> “Elemental Impurities-Procedures” (3). USP <233> provides analysts with flexibility in how to perform the analysis on a given sample, while providing two refereed methods for analysis, inductively coupled plasma-optical emission spectroscopy (ICP-OES) and inductively coupled plasma-mass spectrometry (ICP-MS). Although ICP-MS and ICP-OES have been used for metals analysis in the pharmaceutical industry for quite some time (4,5), the techniques have seen limited application for traditional heavy metals testing (6) because of the availability of the traditional wet chemistry USP <231> “Heavy Metals” (7) test. With the pending retirement of USP <231>, analysts are transitioning to the use of USP <233> to perform any analyses that might be required to complete the risk assessment on a product. For some laboratories, the analysis of pharmaceutical samples using plasma spectrochemistry is new and may present challenges.

Inherent in performing any analysis is the preparation of the sample, which can vary from sample to sample and is a critical and perhaps the most complicated part of the process. One of the frequently used preparation techniques in the field of atomic spectroscopy is acid digestion. Before the advent of modern microwave digestion systems, hot-plate digestions were used as a means to prepare samples for metals analyses. Although they are effective in solubilizing some samples, hot-plate digestions are prone to several potential problems, including loss of potentially volatile analytes such as mercury, sample loss from material spitting out of the digestion container if the sample is rigorously boiled, and simply not providing sufficient heat to adequately dissolve the sample. Studies have been performed comparing the use of hot-plate versus microwave digestion techniques (8–11). As more microwave digestion systems have become commercially available, the use of these systems has become common (12–14), and closed-vessel microwave digestion is the preferred method of sample preparation in USP <233>. The selection of the acid used to perform the digestion is key to the success of the digestion. Most often, nitric acid (HNO3) is used but other acids, such as hydrochloric acid (HCl), sulfuric acid (H2SO4), or hydrofluoric acid (HF) are also commonly used (15).

Unfortunately, acid digestions are not always effective in completely solubilizing a sample for metals analysis. Other approaches for preparing samples for metals analysis include fusion, where a flux mixture is added to samples to help lower the melting point of materials in a sample. This approach also helps to achieve a homogeneous fluidity of melted oxide impurities in the sample (16,17). Fusion, performed with fluxes, is a long-used method in the metallurgical industry for determining gold in ore samples, but this old “fire assay” technique is not commonly used for metals analyses, because the majority of samples do not require this rigorous approach to sample preparation.

Pharmaceutical Samples

When testing is performed to demonstrate that a drug product complies with USP <232> and ICH-Q3D, the manufacturer can elect to test either the drug product or the various components that make up the drug product. In the case of drug product analysis, only the analysis of the drug product is required. Sample preparation procedures may need to be more rigorous, because of the fact that drug products are often mixtures. Additionally, drug products often include capsule shells or tablet coatings that can present challenges in sample preparation and analysis.

In the case of component analysis, however, each component of a drug product must be analyzed individually, significantly increasing the number of analyses required if the manufacturer opts to test components to demonstrate compliance. Given that the individual components are a single matrix and generally pure materials, their analysis may be easier than drug product analysis. Some manufacturers may choose this option since it minimizes the chance of manufacturing a batch of drug product that fails the elemental impurities specification.

Selection of Sample Preparation Procedure

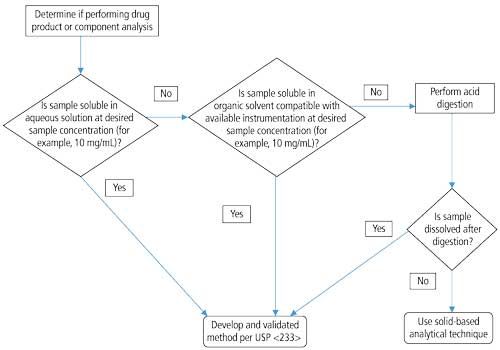

Regardless of whether a drug product or its components are analyzed, USP <233> provides a significant degree of latitude for an analyst performing an elemental impurities determination in a pharmaceutical material, and selecting a sample preparation approach is the first step to performing an analysis with USP <233>. Analysts can opt to use either traditional sample preparation procedures or more innovative approaches, provided that the validation criteria of <233> are met. With many options available, those analysts who have solid analysis capabilities may use them, but most analysts use solution-based techniques. Figure 1 shows one potential way to approach determining which sample preparation technique to use.

Figure 1: Sample solubility flow chart.

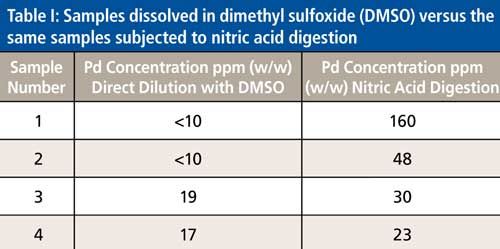

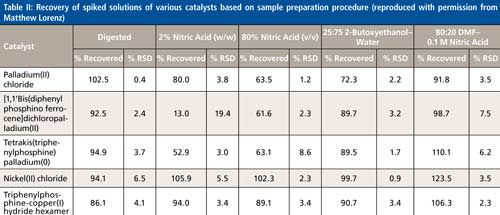

Direct Dilution of Samples

When performing direct dilution, the sample should be readily and completely soluble in the given solvent: an aqueous media or an organic solvent. In such instances, analysts simply dilute the sample and perform the analysis. This approach is often appropriate for preparing a sample for elemental impurities analysis, but there are some caveats. Despite the fact that the sample may appear to be completely soluble, dissolved solids may be present, and the analytes may not be completely soluble. In such cases, a digestion technique may be needed to obtain the correct determination of the elemental impurities concentrations in a given sample. Table I illustrates the danger of assuming that a sample is completely dissolved: the same sample run after both direct dilution with dimethyl sulfoxide (DMSO) and microwave digestion using nitric acid can sometimes yield dramatically different results. This point was further highlighted by Lorenz (18), when he compared direct dilution results for various Pd-, Ni-, and Cu-containing catalysts with results obtained using nitric acid digestion, as shown in Table II.

It is advisable to confirm the accuracy of the results obtained by direct dilution with results obtained on the same samples using a digestion technique to avoid the generation of erroneous results. If results obtained via digestion are consistent with results obtained via direct dilution, then direct dilution is an acceptable approach for sample preparation.

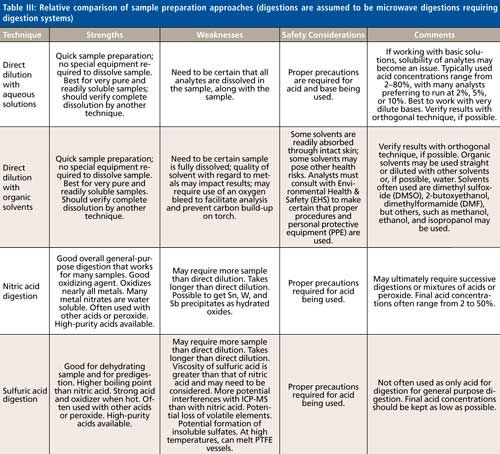

Digestion

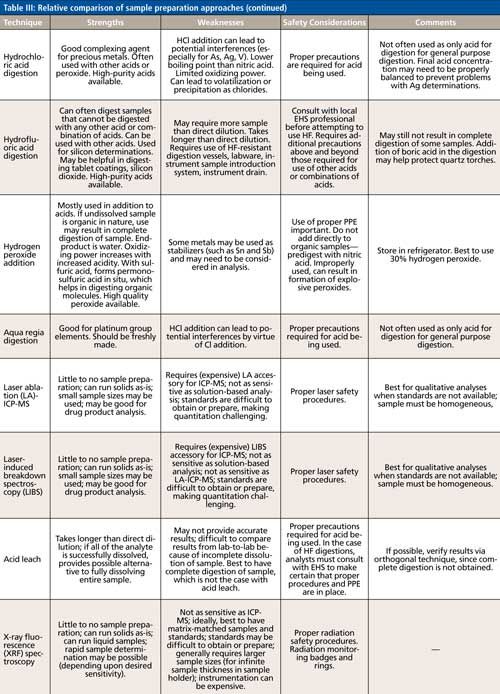

When digestion is required, there are many potential options available to the analyst. Most often, nitric acid is used, however, other acids such as hydrochloric acid, sulfuric acid, and hydrofluoric acid are viable options. Likewise, combinations of acids or successive digestions may also be necessary to effect full digestion of a sample. Table III provides general information regarding some of the more commonly used different digestion approaches, but is not intended to be an exhaustive listing of digestion options. Table III also provides information on some solid-based techniques and direct dilution approaches for purposes of comparison to digestion.

When a Sample Just Won’t Dissolve

Despite best efforts, there are times when a sample cannot be expeditiously dissolved. Analysts may need to weigh efforts expended to completely dissolve a sample with analytical benefits and advantages. In such cases, if possible, an analyst may wish to consider various solid analysis techniques. Laser-induced breakdown spectroscopy (LIBS), laser-ablation ICP-MS (LA-ICP-MS), and X-ray fluorescence (XRF) are the more commonly used techniques, and general information regarding them is provided in Table III. Because these techniques are not available in many laboratories, and because a clear solution is desired, the question then becomes one of whether or not the analytes in question are sufficiently solubilized by the sample preparation procedure used. There has been discussion-especially at conferences (19)-about these so-called “acid leach” procedures. Such procedures should not be undertaken lightly, and require knowledge of the chemistry involved. What is the sample? What are the analytes of interest? What is the solvent being used? Is it reasonable to expect that the analytes of interest would be dissolved in the solvent being used, despite having an undissolved sample? Having a good understanding of the chemistry associated with the sample and analytes is critical in assessing the success of an “unsuccessful” digestion in solubilizing analytes of interest. Even so, it is difficult to compare results obtained from multiple analyses using acid leach procedures, making it difficult to be certain that results are accurate. Consequently, if at all possible, orthogonal, solid-based analytical techniques should be used to help assess the success of an “unsuccessful” digestion to adequately dissolve analytes.

Conclusion

The sample preparation procedure is key to the success of an elemental impurities analysis, and while USP <233> provides a great deal of latitude in the preparation of a sample, some in the pharmaceutical industry may not be as familiar with various sample preparation options. Pharmaceutical samples can be prepared in a wide variety of ways and analysts can leverage procedures and experiences gained from other industries to perform such analyses on pharmaceutical samples. As the pharmaceutical industry begins to become more accustomed to performing elemental impurities analyses, analysts will be more confident in their ability to perform them.

References

- http://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q3D/ Q3D_Step_4.pdf.

- .

- .

- N. Lewen, M. Schenkenberger, T. Larkin, S. Conder, and H. Brittain, J. Pham. Biomed. Anal. 13, 879–883 (1995).

- T. Wang, Z. Ge, J. Wu, B. Li, and A. Liang, J. Pharm. Biomed. Anal.19, 937–943 (1999).

- N. Lewen, S. Mathew, M. Schenkenberger, and T. Raglione, J. Pharm. Biomed. Anal.35, 739–752 (2004).

- USP38-NF33, General Chapter <231> ”Heavy Metals,” Pharmacopeial Forum39(1), 241.

- K.M.Dimpe, J.C. Ngila, N. Mabuba, and P.N. Nomngongo, Physics and Chemistry of the Earth, Parts A/B/C76–78, 42–48 (2014).

- J.M. Cook, M.J. Gardner, A.H. Griffiths, M.A. Jessep, J.E., Ravenscroft, and R. Yates, Marine Pollution Bulletin34(8), 637–644 (1997).

- Z. Kowalewska, E. Bulska, and A. Hulanicki, Fresenius J. Anal. Chem.362, 125–129 (1998).

- V. Sandroni, C.M.M. Smith, and A. Donovan, Talanta60(4), 715–623 (2003).

- Q. Jin, F. Liang, H. Zhang, L. Zhao, Y. Huan, and D. Song, Trends Anal. Chem.18(7), 479–484 (1999).

- F.E. Smith and E.A. Arsenault, Talanta43, 1207 (1996).

- H. Matusiewicz, Anal. Chem.66, 751 (1994).

- Analytical Chemistry of Minerals, A. Samchuk adn T. Pilipenko, Eds; translated by S.V. Ponomarenko (VNU Science Press BV, The Netherlands, 1987), pp. 36–39.

- M. Lorenz, “Analysis of Residual Metals in API by Inductively Coupled Plasma- Mass Spectrometry- A Practical Evaluation of Sample Preparation Techniques,” presented at the Eastern Analytical Symposium (EAS), Somerset, New Jersey, 2005.

- D. Seibert, “Analytical Challenges/Round Robin Study,” presetend at the PRI/USP Workshop on Elemental Impurity Requirements in a Global Environment--Next Steps? Rockville, Maryland, 2015.

Nancy Lewen is with Bristol-Myers Squibb Analytical and Bioanalytical Development in New Brunswick, New Jersey. Direct correspondence to: Nancy.Lewen@BMS.com

Geographical Traceability of Millet by Mid-Infrared Spectroscopy and Feature Extraction

February 13th 2025The study developed an effective mid-infrared spectroscopic identification model, combining principal component analysis (PCA) and support vector machine (SVM), to accurately determine the geographical origin of five types of millet with a recognition accuracy of up to 99.2% for the training set and 98.3% for the prediction set.

Authenticity Identification of Panax notoginseng by Terahertz Spectroscopy Combined with LS-SVM

In this article, it is explored whether THz-TDS combined with LS-SVM can be used to effectively identify the authenticity of Panax notoginseng, a traditional Chinese medicine.