A Look at Inorganic Analyses, Proficiency Tests, and Best Practices, Part II

The use of proficiency tests (PTs) in an analytical inorganics laboratory is an essential part of assuring clients the laboratory is producing accurate results. In the first part of this two-part series, we examined the ways in which contaminants can alter the results in a detrimental fashion in regard to proficiency testing and laboratory audits. In Part II, we examine the actual planning, running, and reporting of a PT scheme and the possible impact of error and contamination.

A proficiency test (PT) scheme does not start only upon opening the ampule or bottle to test the sample. The steps that lead up to the actual testing can play an important role in the success or failure of a testing scheme. As was discussed in the previous column, standards, calibrations, and maintenance are all important components in reducing error and contamination even before the first sample is placed on the instrument. Once the laboratory and all its contributing standards and equipment are ready, it is time to turn the attention to the actual PT sample.

Starting a PT

The proper handing and processing of a PT sample can be critical in passing a PT test. For calendar-based PTs, one needs to check for shipping dates and delays, which could affect the quality of the PT. Upon receipt of the PT sample, open the package and check its condition. Report any damage to samples or if they have been thermally compromised. The first step after receiving and accepting the PT shipment is to check all of the handling and safety instructions to ensure that the samples are kept at their optimal conditions.

Some materials may require temperature control whereas others may have instructions on how to handle the sample during preparation or give information regarding the possible range of values for the PT. Once the PT is in-house, fresh chemicals and standards should be prepared and all calculations should be rechecked. Check PT instructions for methods and report results (that is, online, by phone, or by mail), and the correct reporting formats that are acceptable (that is, correct weight or concentration notations).

Take special note of any sample preparation procedures or method notes that are to be employed with that PT scheme. Any differences between your normal sample preparation and the PT preparation and analysis should be discussed with the quality manager. Otherwise, all differences in sample preparation because of the matrix or material should reveal the deviations or additions to prepare the sample that differ from routine preparation.

PT Calculations and Results

Once a PT has been analyzed, the data is reported back to the PT provider for analyses and final acceptance. The PT provider often has multiple methods for evaluating the data based on the type of PT that is being analyzed and the governing bodies under which the PT scheme is intended. Some accreditation or standards organizations offer documentation and tables for the reporting of PT results, whereas other PT results are entered into programs to create results from programmed algorithms and statistics.

ISO guidelines (ISO 13528) have two basic methods for the statistical evaluation of proficiency tests: the En-value and the z-score. An En-value is most commonly used in interlaboratory comparisons where the laboratories report their uncertainty calculations (equation 3).

Results with an En-value between 1 and -1 are considered successful and in agreement with the reference values. Results with En-values greater than one or less than -1 are considered not successful and disagree with the reference values, which should trigger a corrective action.

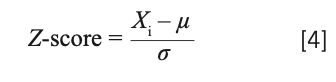

The z-score can also be conducted within interlaboratory comparisons without an uncertainty calculation, but the z-score assumes all samples reported are from the same population, batch, or sampling; therefore, all samples have the same uncertainty. The most practical of the statistical functions for chemical and biological analyses is the z-score (equation 4).

The results are calculated after the outliers are removed or are obtained from robust statistics. Z-scores less than two are considered successful and in agreement with accepted values. Scores between two and three are considered suspect whereas scores greater than three are unsuccessful and disagree with the accepted results.

Once scores are compared against the reference values and are assigned passing or failing scores, those scores are reported to the laboratories. Scores can either reflect individual scores for individual analysts or they can reflect the overall laboratory proficiency. In many cases, one unsuccessful score does not necessarily mean that the entire laboratory fails the PT scheme. One or more assessed failures in key practices or tests can cause a laboratory performance to be deemed unsatisfactory or multiple failures submitted in one PT round. Multiple consecutive failures for an analysis can also result an unsatisfactory rating. Results of a particular analysis may be deemed suspect if a clear bias or trend towards unsatisfactory results is apparent, including consistent bias over one standard deviation above or below the assigned values. Even if the results themselves are passing, the PT results can be considered unsatisfactory if there is a clear and measured bias. All failures or unsatisfactory results should be directed towards root cause analysis and corrective actions as dictated by that laboratories’ quality management system (QMS).

Corrective Actions

In the event that an analyst or laboratory fails a PT test, there should be a procedure for a comprehensive review of the processes, preparation, and analyses involved, along with a plan of action to correct the problems found. First, a root cause analyses is conducted to identify and document the problem. Then, a decision is made whether the problem was because of an error or a systematic defect that needs to be corrected. In cases of error, a full corrective action may not be required, but instead, a retraining for that analyst or laboratory. If a root cause analysis finds deficiencies within a system, then a corrective action is devised to remedy the issue. A retesting of a corrected system must be conducted to determine if the correction was successful.

Some of the points of review should include the laboratory processes and all internal quality control data. Points to reexamine during a system and procedure review for a PT failure include:

- Sample storage and handling—were all requirements met?

- Preparation—did the preparation process differ between normal samples and the PT samples?

- Instrumentation and equipment—does the deficiency lie within the system, and can it be corrected with replacement, repair, or recalibration?

- Environment—were all materials and equipment kept at the correct temperature?

- Controls—were all the standards, QC samples, and controls within expiration? Were samples and standards prepared fresh or were new standards opened?

- Calibrations—are all the dilutions correct and within the correct dynamic range for the system? Were all the calculations correct and documented including unit conversions?

- Are there sources of contamination that may have caused the deviation in results?

Sources of Laboratory Contamination and Error

It is hard to imagine that such tiny amounts of contamination can dramatically change laboratory values. In most cases, the root of that contamination can be traced to a common source. The most common sources of contamination, in addition to the previously discussed volumetric labware, are water, reagents, laboratory environment, and personnel.

Water is one of the most basic yet most essential laboratory components. There are many types, grades, and intended uses for water. Inferior quality water can cause a host of problems from creating deposits in labware or inadvertently increasing a target element or element concentration in solution.

The actual type of water produced by a commercial laboratory water filtration system can vary in pH, solutes, and soluble silica. Critical analytical processes should always require a minimum quality of American Society for Testing and Materials International (ASTM) Type I water. All trace analysis should be conducted with the highest purity water. Analysts who use certified reference materials (CRMs) and perform quantitative analysis need to use quality water to prevent contaminating their CRMs, standards, PTs, and samples with inferior quality water.

Another source of contamination are all the chemicals used in sample processing. Just as in the case of water, there are several types or grades of chemicals, reagents, acids, and solvents. Some designations are set forth by standards set by national or international organizations other types or grades of material are designated by individual manufacturers based on intended use. Some grades are general laboratory grades with intended use for noncritical applications, whereas other grades high in purity and low in contaminants are designated for more critical analyses.

For example, consider acids, which by their very nature are oxidizers and many of the strongest acids are used in the processing of samples for inorganic analysis. Common acids in digestion and dissolution, such as perchloric acid, hydrofluoric acid, sulfuric acid, hydrochloric acid, and nitric acid, are commercially available in several grades from general laboratory or reagent grade to high purity trace metal grade. Acid grades often reflect the number of distillations the acid undergoes for purification before bottling. The more an acid is distilled, the higher the purity of the acid. These high purity acids have the lowest amount of elemental contamination but can become very costly.

To reduce contamination, it is recommended that high purity acids be used to dilute and prepare standards and samples when possible. In addition to using pure acid, it is important that the chemist check the certificate of the acid under analysis to identify the elemental contamination levels present in the acid.

Laboratory Environment and Personnel

All laboratories believe they observe a respectable level of laboratory cleanliness. Most chemists recognize there are inherent levels of contamination present in all laboratories. A common belief is that the tiny amounts of environmental and laboratory contamination cannot profoundly change the analytical results. Spex conducted a test where nitric acid was distilled in both a clean room and a normal preparation laboratory. The nitric acid distilled in the regular laboratory had considerable amounts of aluminum, calcium, iron, sodium, and magnesium contamination not found to the same degree as in the clean room.

Laboratory air also can contribute to the contamination of samples and standards. Common sources of air and particulate matter contamination are from surfaces and building materials. Surface contaminants can be found in dust and rust on shelves, equipment, and furniture. Dust contains many different earth elements such as sodium, calcium, magnesium, manganese, silicon, aluminum, and titanium. Dust can also contain elements from human activities (Ni, Pb, Zn, Cu, and As).

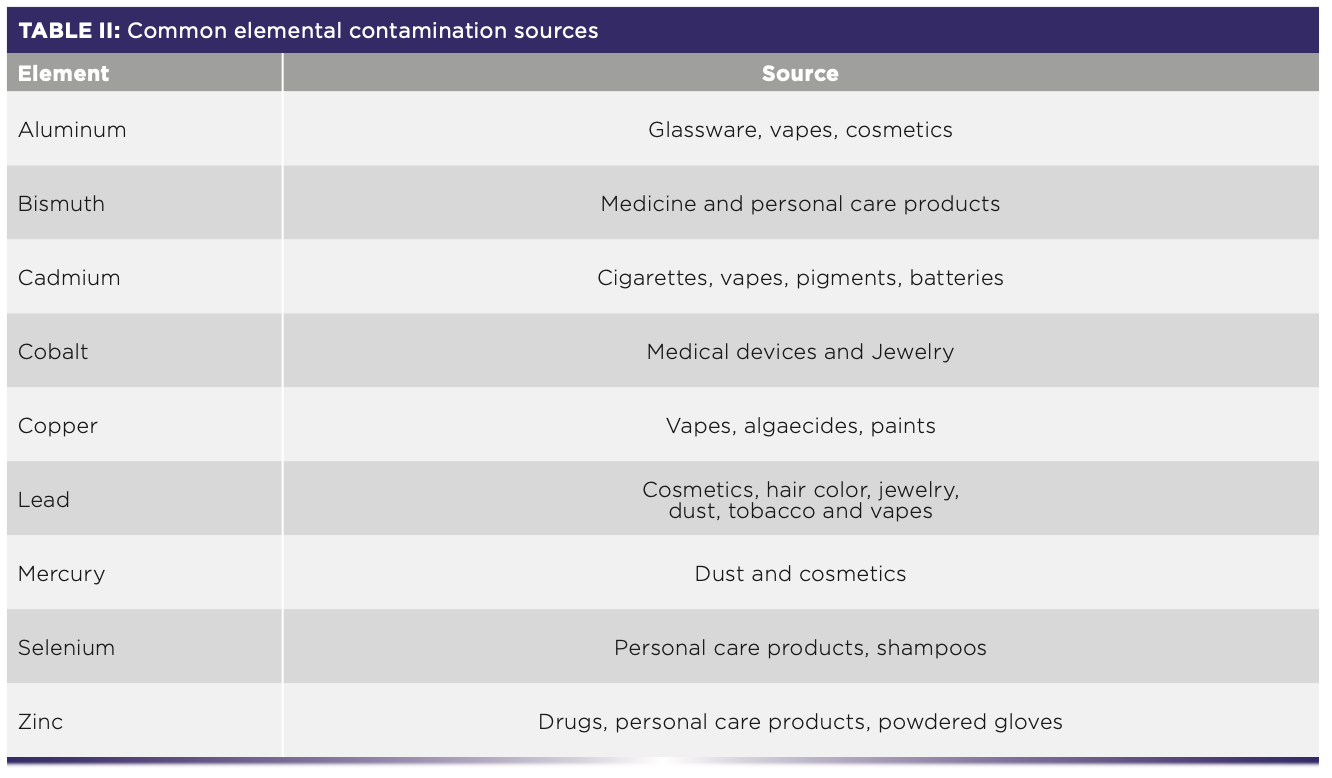

Laboratory personnel can add their own contamination from laboratory coats, makeup, perfume, and jewelry. Many other common elements can be brought in as contamination from personal care products. Even sweat and hair can cause elevated levels of sodium, calcium, potassium, lead, magnesium, and other ions. If a laboratory is seeing an unusually elevated level of cadmium or other heavy metals in the samples, it could be from cigarettes, pigments, or batteries. If the levels of lead are out of range, contamination can be from paint, cosmetics, and hair dyes (Table II).

Even with clean laboratory practices in place, erroneous results can often find their way into sample analysis. To eliminate some of these spurious results, replication of blanks and sample dilutions can be employed. The blank results should be averaged, and the sample run or PT values can either be minimally selected or averaged. The difference between the two values can then be plotted against a curve established against two more standards. A minimum of two standard points can be used if the chance of contamination is minimal, such as in the case of rare or uncommon elements. Additional standard points should be considered if the potential for contamination is high with common elements, such as aluminum, sodium, and magnesium. Multiple aliquots of blanks and dilutions can also be employed to further minimize analytical uncertainty.

Limitations of PTs

As we have discussed, PTs are a necessary and helpful tool in the QMS system arsenal of a laboratory; but they do have limitations and misuses. In PT schemes where interlaboratory tests are used to establish values, there is often a retrospective aspect to the tests. These tests take time and have very time-critical periods for analyses in order for the results to be included in the data set. In many cases, the PTs available only include a small subset of analytes or matrices that a laboratory will analyze on a routine basis, meaning only those types of samples or target analytes are covered by the PT, whereas the others remain unmonitored.

There are often routine samples or analyses not reflected by the PT schemes either because the PT available is in a different sample format or matrix than the one routinely evaluated. For example, if a laboratory tests pesticides in plant extracts with alcohol-based matrices (for example, tinctures), but the PT is pesticide in oil extract or plant material, then the PT doesn’t completely reflect the state of the preparation routine to that laboratory.

Another problem or limitation of a PT is that it only indicates when a problem is present but does not provide any information in regard to the root cause of the problem. PT should not be used as a substitute for quality controls within a laboratory. Conversely, a successful PT study result does not indicate competence in other laboratory areas of testing.

Final Thoughts

PTs serve to measure the ongoing proficiency of independent laboratories through interlaboratory comparison of test results for the same characterized material. PT participation is often stipulated by the regulatory authority overseeing laboratories operations or an accrediting body to which laboratories comply, or sometimes both authorities concurrently. It is best to consider the laboratories accreditation goals and regulatory requirements when determining the schedule and budget for PTs participation. It is best to perform PTs at least annually to monitor laboratory performance during a twelve-month period. Longer stretches without PTs participation could negatively impact timely identification of nonconformance and delay implementation of effective corrective action. PTs are useful as tools to verify continuous improvement, resolve or monitor effective corrective actions, and demonstrate training and competency for laboratory analysts. PTs are a multipurpose external quality assessment tool and should be an integral part of the laboratory QMS.

Further Reading

(1) International Organization for Standardization. (2010). Conformity Assessment – General Requirements For Proficiency. (ISO/IEC Standard No. 17043).

(2) International Organization for Standardization. (2017). General Requirements For the Competence of Testing and Calibration Laboratories (ISO/IEC Standard No. 17025).

(3) USP, USP Proficiency Testing Program. www.usp.org/proficiency-testing (accessed June 2022)

(4) NSI Laboratory Solutions, Proficiency Testing. www.nsilabsolutions.com/proficiency-testing/ (accessed June 2022).

(5) Spex CertiPrep Webinar, Clean Laboratory Techniques. https://www.spexcertiprep.com/webinar/clean-laboratory-techniques (accessed June 2022).

(6) American Society for Testing and Materials. (2018). Standard Specification for Reagent Water (ASTM Standard No. D1193-06).

(7) Spex Knowledge Base for white papers on dilutions, calibrations, and standards. www.spex.com/KnowledgeBase/AppNotesWhitepaper (accessed June 2022).

ABOUT THE CO-AUTHORS

Patricia Atkins is a Senior Applications Scientist with Spex, an Antylia Company who specializes in scientific content and education for the analytical community.

Lauren Stainback is the Global Product Manager for NSI Lab Solutions Inc. (a Spex/Antylia Scientific company), leading NSI’s product and business development efforts.

ABOUT THE COLUMN EDITOR

Robert Thomas, the editor of the “Atomic Perspectives” column, is the principal of Scientific Solutions, a consulting company that serves the educational and writing needs of the trace element analysis user community. Rob has worked in the field of atomic spectroscopy and mass spectrometry for more than 45 years, including 24 years for a manufacturer of atomic spectroscopic instrumentation. He has authored more than 100 scientific publications, including a 15-part tutorial series, “A Beginners Guide to ICP-MS.” In addition, he has authored five textbooks on the fundamentals and applications of ICP-MS. His most recent book, a paperback edition of Measuring Heavy Metal Contaminants in Cannabis and Hemp was published in December 2021. Rob has an advanced degree in analytical chemistry from the University of Wales, UK, and is a Fellow of the Royal Society of Chemistry (FRSC) and a Chartered Chemist (CChem). Direct correspondence to SpectroscopyEdit@mmhgroup.com. ●

LIBS Illuminates the Hidden Health Risks of Indoor Welding and Soldering

April 23rd 2025A new dual-spectroscopy approach reveals real-time pollution threats in indoor workspaces. Chinese researchers have pioneered the use of laser-induced breakdown spectroscopy (LIBS) and aerosol mass spectrometry to uncover and monitor harmful heavy metal and dust emissions from soldering and welding in real-time. These complementary tools offer a fast, accurate means to evaluate air quality threats in industrial and indoor environments—where people spend most of their time.

New Raman Spectroscopy Method Enhances Real-Time Monitoring Across Fermentation Processes

April 15th 2025Researchers at Delft University of Technology have developed a novel method using single compound spectra to enhance the transferability and accuracy of Raman spectroscopy models for real-time fermentation monitoring.