Analysis of Transdermal Patch Layers via Confocal Raman Microscopy

A transdermal patch is a method of drug delivery through the skin into the bloodstream that is composed of layers that store and release the active pharmaceutical ingredient (API) over time. The ability to analyze these layers without damaging the patch allows for quality control and stability measurements. Raman spectroscopy has excellent chemical identification abilities, thanks to the fingerprint like spectrum it produces, that deliver rapid discrimination between components typically found in transdermal patches, such as polymers and APIs. Coupling this with a confocal microscope gives high spatial resolution on all three axes, with the pinhole providing otherwise unachievable axial resolution, permitting depth profile analysis. Using this technique, the patch can be analyzed from top to bottom without any risk of damage. This article highlights the use of confocal Raman microscopy to acquire a 3D Raman map of a transdermal patch for layer evaluation. The map revealed six layers which were composed of four polymers and the API layer at the center of the patch.

A transdermal patch is a method of drug delivery through the skin into the bloodstream (Figure 1). The patch contains a drug that absorbs into the skin; the patch releases a consistent and controlled amount of medication into the body over long periods time. This method of delivery is preferred in cases where the drug can have negative side effects on the gastrointestinal tract, for prolonged drug release, or as an option for people with a fear of needles looking to avoid medication delivered via injection.

FIGURE 1: A typical transdermal patch and its layer composition.

One of the most common uses for transdermal patches is to help combat nicotine addiction. Nicotine patches were first developed in the 1980s as a method to help people quit smoking after several studies proved the absorption of nicotine into the body reduced cravings. Nicotine replacement therapy (NRT) releases small amounts of nicotine throughout the day, without the additional harmful components of cigarettes, such as tar. A recent review of data from the public and from clinical trials revealed that using NRT can increase the chance of successfully quitting smoking by up to 60% (1).

Analyzing multilayer polymers, such as transdermal patches, can provide manufacturers and researchers with important information on the quality of their product. Probing into the layers allows validation of the amount and distribution of the active pharmaceutical ingredient (API) within a patch, as well as identifying any contaminants. Achieving this without sample damage or alteration is critical for providing meaningful data on real-life products. Raman microscopy is an extremely sensitive technique for polymer identification, and coupling to a confocal microscope allows high spatial resolution in the z-axis for investigating different layers.

Confocal Raman Microscopy

Raman spectroscopy can be used for identification of polymers due to its fingerprint-like level of sensitivity. Each peak in a Raman spectrum can be thought of as the fingerprint of a specific molecular vibration from the sample, meaning polymer spectra can easily be distinguished. For example, the technique is sensitive enough to identify co-polymers and determine differences between high- and low-density polyethylene. Furthermore, its non-destructive nature allows analysis of samples to be analyzed without any damage or need for sample preparation (2).

Databases of known polymers can be developed, meaning unknown samples can be compared to these spectra for identification, thus adding to the speed and accuracy of polymer identification by Raman spectroscopy. For example, the database applies a best fit comparison of the measured spectra with those in its library, and carries out a series of optimized corrections to provide the best possible match against its database.

The skill set of Raman spectroscopy can be further enhanced by incorporating a confocal microscope where the Raman laser will be directed though a microscope containing a pinhole, enabling the analysis volume to be defined with simultaneously high lateral (xy) and axial (z) resolution, allowing the analysis of discrete sample features and layers down to less than 1 μm in size (3).

Role of the Pinhole

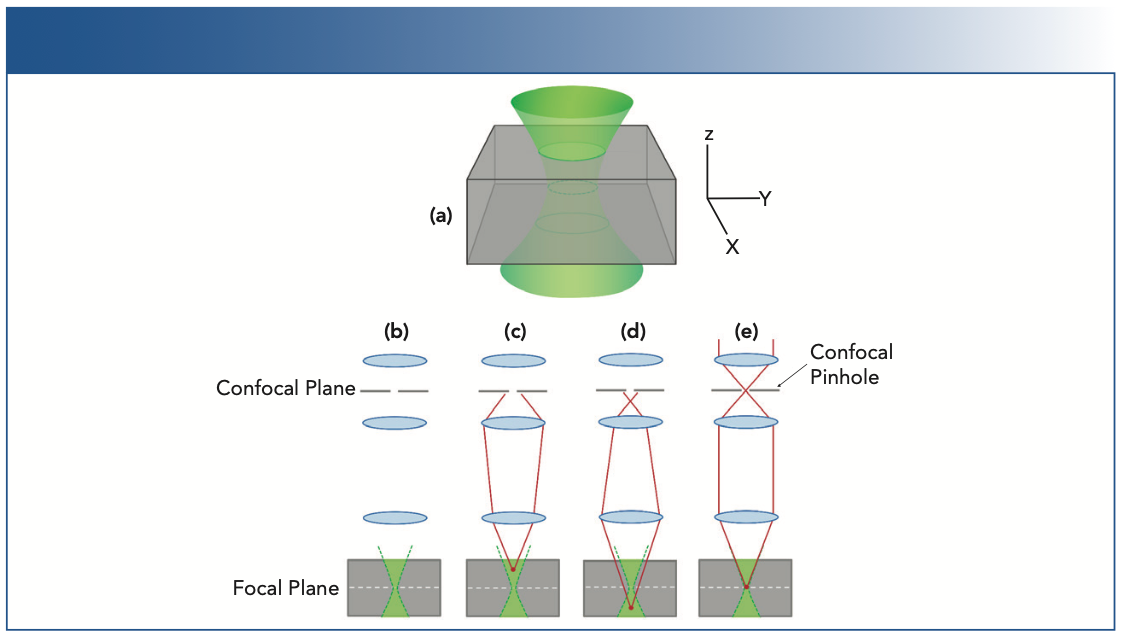

When laser light is focused into a sample by a Raman microscope, a three-dimensional excitation volume is formed within the sample. This volume is known as the excitation point spread function (PSF), and a representation of its shape is shown in Figure 2a. As the light converges towards the focal point, the diameter of the PSF decreases, reaching a diffraction-limited minimum diameter at the focal plane followed by an increase in diameter as the light diverges. The exact shape of the PSF is heavily dependent on the optical properties of the sample, such as opacity at the excitation wavelength, refractive index, and how it scatters the incident excitation. Raman scattering will occur throughout the entire excitation volume, and simply measuring the Raman spectrum from this excitation would, therefore, result in spectral contributions from the entire volume with limited axial (z-axis) discrimination.

FIGURE 2: Role of the confocal pinhole in a Raman microscope: (a) representation of the excitation 3D point spread function, (b) excitation cone induces Raman scattering throughout the sample volume, (c) Raman scatter originating from above the focal plane is rejected by the confocal pinhole, (d) Raman scatter originating from below the focal plane is rejected by the confocal pinhole, (e) Raman scatter originating from the focal plane is passed through the pinhole and enters the spectrograph for detection.

The role of the confocal pinhole is to spatially filter the analysis volume so that the Raman scatter is detected from the focal plane only; its operation is illustrated in Figures 2b-e. Raman scatter that originates either above Figure 2c or below Figure 2d the focal plane is not brought to a focus in the confocal plane; rather, it is blocked by the confocal pinhole and not detected. In contrast, Raman scatter that originates from the focal plane is brought to a focus in the confocal plane and passes through the pinhole and is detected. This is the meaning of the word confocal; to share the same focal point, and Raman scatter from inside the excitation focus will also be in focus at the pinhole (4).

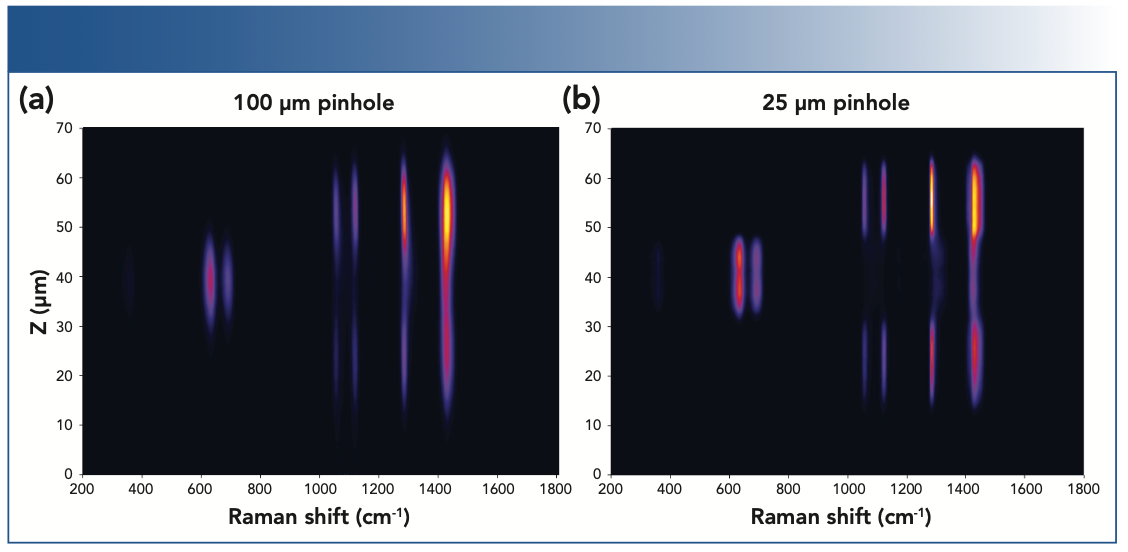

The addition of the pinhole allows for 3D analysis, which is particularly useful for multilayer samples, such as composite plastics. The polyethylene terephthalate (PET) and polyvinyl chloride (PVC) polymers have unique Raman spectra, and the Raman depth profile can identify the discrete layers within the PET-PVC-PET polymer stack. It can clearly be seen in Figure 3 that, as the diameter of the pinhole is decreased from 100 μm to 25 μm, it becomes increasingly effective at blocking the out-of-focus scatter (increased confocality), and the effective axial resolution improves. Using narrow pinhole diameters, axial resolutions of <1 μm can be achieved. The tradeoff with narrowing the pinhole diameter is that the throughput of the microscope is significantly lowered, and measurements will therefore take longer, due to decreased Raman scatter intensity at the detector. Due to this tradeoff, most Raman microscopes use a variable diameter confocal pinhole enabling the microscope mode to be adjusted from high confocality/low throughput to non-confocal/high throughput, depending on the application.

FIGURE 3: Raman depth profile of a multilayer polymer sample comprised of a PET-PVC-PET stack measured with a 532 nm laser and a 100x 0.9 NA objective and (a) 100 μm pinhole and (b) 25 μm pinhole.

Experimental

An Edinburgh Instruments RMS1000 Raman Microscope was used for the 3D measurement of a transdermal nicotine patch. The nicotine patch was a commercially available NRT purchased from a pharmacy. The microscope was equipped with a 100 x 0.9 numerical aperture (NA) objective; this also ensures high resolution. The choice of objective lens is important as the NA of the objective lens and the laser wavelength determine laser spot size on the sample and the spatial resolution of the Raman mapping.

The 3D Raman map of the patch was acquired with a 785 nm laser at 100% power with an exposure time of 0.5 s and the pinhole set to 200 μm. A slit width of 70 μm was used along with a 600 gr/mm grating and a back illuminated CCD. The total sample height was approximately 4 mm and Raman spectra were acquired every 10 μm in the z-dimension. The library used for spectral identification was the KnowItAll Raman Database.

Results and Discussion

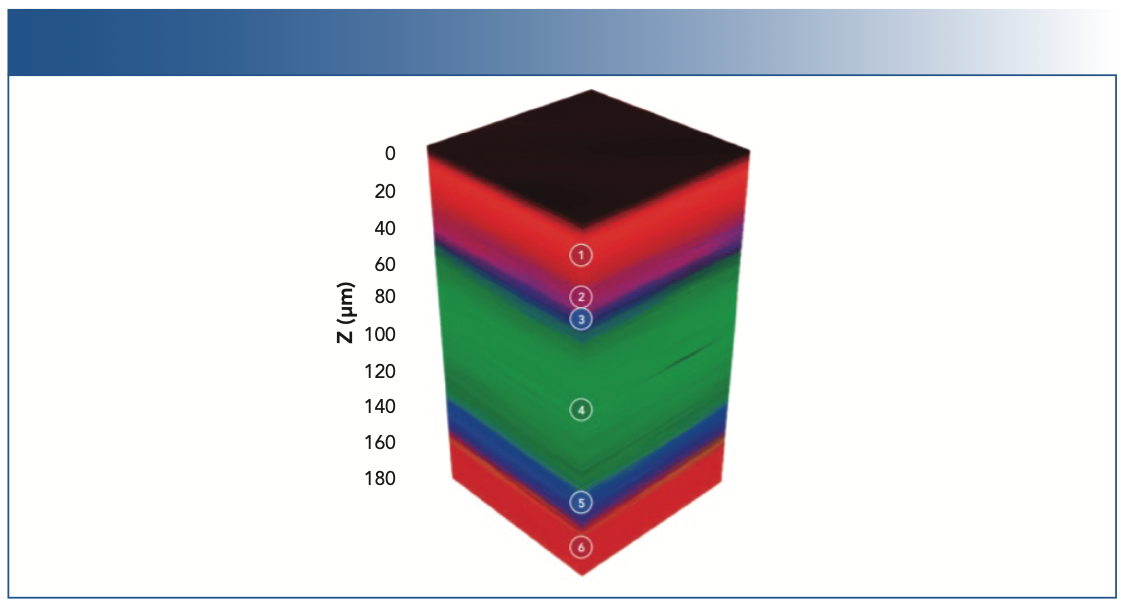

The transdermal patch analyzed contained nicotine as the active ingredient, surrounded by polymers. By carrying out a Raman 3D map, we can visualize the different material layers present in the patch, shown in Figure 4 as a 3D render.

FIGURE 4: 3D Raman depth profile map of a transdermal nicotine patch (x, y, and z axes shown).

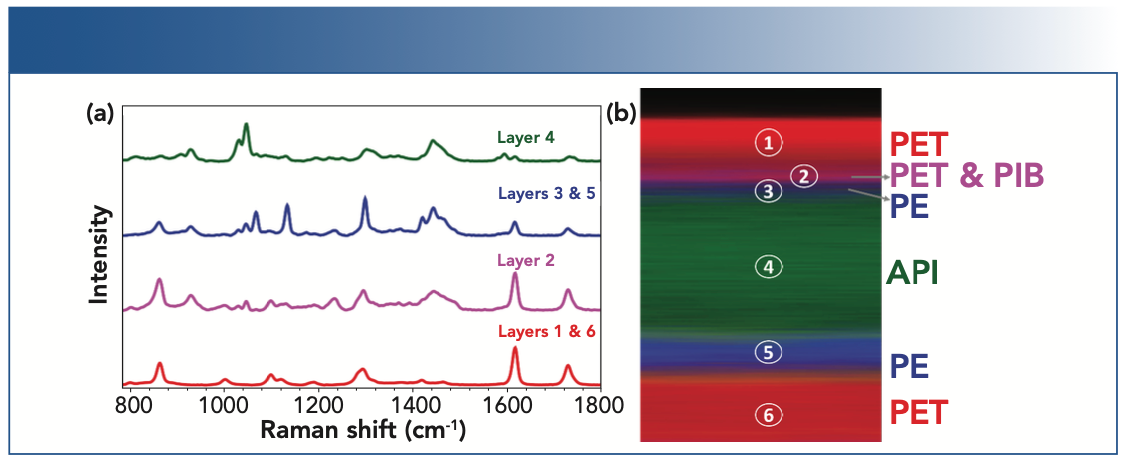

The 3D Raman map (Figures 4 and 5) reveals the patch contains six layers, and the spectrum of each layer can be extracted and analyzed for identification. The outer layers of the patch, layers 1 and 6, shown in red, can be identified as poly(ethylene terephthalate) (PET) using the spectral database. The 3D map is colored based on peaks specific to the material identified (for example, for the layers of PET the peak at 1293 cm-1 was selected). Layer 2 can be identified as PET/polyisobutylene, labeled in pink, based on the 1233 cm-1 peak, and layers 3 and 5, which surround the API, were determined to be polyethylene (PE), highlighted in blue from its peak at 1442 cm-1. Finally, in the middle of the polymers is a thick layer of the API, nicotine, embedded in a polymer reservoir (ethylene). This is shown in green, and is attributed to peaks at 1045 cm-1 and 1030 cm-1. Layer 1 is the release liner of the patch; this layer is responsible for protecting the medication and adhesive, and is removed before application. Layer 2 is the adhesive part of the nicotine patch, layers 3 and 5 are microporous PE which control the release of the API in layer 4, and layer 6 is the backing, which provides protection to the medication while the patch is being worn.

FIGURE 5: (a) Raman spectra from each component, (b) x, z cross section of the sample is illustrated.

Conclusion

The data presented details how confocal Raman microscopy can be utilized to analyze multilayer polymer samples. In the case of this transdermal patch, the API (in this case, nicotine) can be visualized, as can the surrounding polymers responsible for protecting and ensuring the release of the API. Thanks to the fingerprint-like chemical identification offered by Raman spectroscopy, successful spectral evaluation was possible for each of the different polymers present. The confocal microscope allowed for the z-axis to be investigated, resulting in layer thickness to also be assessed. The sample was rapidly analyzed and remained intact and unaltered throughout the experimental procedure. In this way, confocal Raman microscopy is a useful technique for pharmaceutical laboratories to quality control their products and ensuring they have been produced correctly without contaminants, as well as to help monitor the stability of adhesive layers.

References

(1) J. Hartmann-Boyce, S.C. Chepkin, W. Ye, C. Bullen, and T. Lancaster, Cochrane Database Syst. Rev. CD 000146(5), 1–5 (2018). DOI:10.1002/14651858.CD000146.pub5

(2) E. Smith and G. Dent, Modern Raman Spectroscopy (John Wiley & Sons, West Sussex, United Kingdom, 2005). DOI:10.1002/9781119440598

(3) G. Giridhar, R.R.K.N. Manepalli, and G. Apparao, in Micro and Nano Technologies, Spectroscopic Methods for Nanomaterials Characterization, Volume 2, S. Thomas, R. Thomas, A.K. Zachariah, and R.K. Mishra, Eds. (Elsevier, Cambridge, United Kingdom, 2017) pp. 141–161. DOI:10.1016/B978-0-323-46140-5.00007-8

(4) J. Toporski, T. Dieing, and O. Hollricher, Eds., Confocal Raman Microscopy (Springer, Cham, Switzerland, 2nd ed., 2018), vol. 66. DOI:10.1007/978-3-319-75380-5

Angela Flack is an applications scientist with Edinburgh Instruments in Livingston, in the United Kingdom. Direct correspondence to: angela.flack@edinst.com

AI-Powered SERS Spectroscopy Breakthrough Boosts Safety of Medicinal Food Products

April 16th 2025A new deep learning-enhanced spectroscopic platform—SERSome—developed by researchers in China and Finland, identifies medicinal and edible homologs (MEHs) with 98% accuracy. This innovation could revolutionize safety and quality control in the growing MEH market.

New Raman Spectroscopy Method Enhances Real-Time Monitoring Across Fermentation Processes

April 15th 2025Researchers at Delft University of Technology have developed a novel method using single compound spectra to enhance the transferability and accuracy of Raman spectroscopy models for real-time fermentation monitoring.

Nanometer-Scale Studies Using Tip Enhanced Raman Spectroscopy

February 8th 2013Volker Deckert, the winner of the 2013 Charles Mann Award, is advancing the use of tip enhanced Raman spectroscopy (TERS) to push the lateral resolution of vibrational spectroscopy well below the Abbe limit, to achieve single-molecule sensitivity. Because the tip can be moved with sub-nanometer precision, structural information with unmatched spatial resolution can be achieved without the need of specific labels.