Bal Seal Engineering Inc

Company Description

Bal Seal Engineering, Inc. makes custom components that drive tomorrow's technologies. The company is a leading global provider of custom-engineered sealing, connecting, conducting, and EMI/RFI shielding and grounding solutions for analytical equipment, and it applies 50+ years of problem-solving experience to help OEMs and tier suppliers address their toughest engineering challenges. Products employ unique Bal Spring(r) canted coil spring technology to promote enhanced equipment performance and reliability.

Chief Spectroscopic Techniques Supported

- Quadrupole LC–MS

- TOF LC–MS

- MALDI-TOF MS

- ICP-MS

- Atomic spectroscopy

Markets Served

Bal Seal Engineering products improve the performance of liquid handling, chromatography, and diagnostic equipment. The company's Bal Seal(r) spring-energized seals ensure

performance accuracy and product consistency in multi-channel pipettors, and also enable designers of HPLC, UHPLC, SFC, and diagnostic pumps to answer end-user demand for better throughput, sample resolution, and reduced equipment downtime. The company's Bal Spring(r) canted coil springs ground and efficiently transfer electrical current in mass spectrometers and other spectroscopy instruments.

Major Products/Services

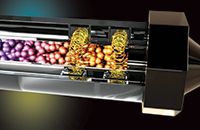

Bal Seal Engineering designs seals that deliver reliable, long-term performance in liquid chromatography pumps, and springs with mechanical fastening and electrical conducting properties. The company's reciprocating flange seal combines the Bal Spring(r) energizer with advanced polymer formulations to promote more uniform wear and longer service life. In UHPLC pressures of 15,000 PSI and above at temperatures up to 80 °C, it seals consistently for millions of cycles. The canted coil Bal Spring(r) enables mass spec designers to achieve constant ion alignment, no contamination, more accurate m/z measurement and minimal downtime.

Facility

Bal Seal Engineering designs and manufactures its products in two U.S. locations-Foothill Ranch, CA and Colorado Springs, CO. The company has built a network of engineering and sales offices worldwide, with locations in The Netherlands, Germany, Czech Republic, Hong Kong, and Japan.

Bal Seal Engineering, Inc.

19650 Pauling

Foothill Ranch, CA

TELEPHONE

US: (800) 366-1006

(949) 460-2100

Europe: +31 20 638 6523

Asia: +(852)-28681860

FAX

US: (949) 460-2300

Europe: +31 20 625 6018

Asia: +(852)-22956753

WEB SITE

NUMBER OF EMPLOYEES

600 worldwide

YEAR FOUNDED

1958

Best of the Week: AI and IoT for Pollution Monitoring, High Speed Laser MS

April 25th 2025Top articles published this week include a preview of our upcoming content series for National Space Day, a news story about air quality monitoring, and an announcement from Metrohm about their new Midwest office.

LIBS Illuminates the Hidden Health Risks of Indoor Welding and Soldering

April 23rd 2025A new dual-spectroscopy approach reveals real-time pollution threats in indoor workspaces. Chinese researchers have pioneered the use of laser-induced breakdown spectroscopy (LIBS) and aerosol mass spectrometry to uncover and monitor harmful heavy metal and dust emissions from soldering and welding in real-time. These complementary tools offer a fast, accurate means to evaluate air quality threats in industrial and indoor environments—where people spend most of their time.