The Benefits of Single-Particle ICP-MS to Better Understand the Fate and Behavior of Engineered Nanoparticles in Environmental Water Samples

Special Issues

SP-ICP-MS demonstrates excellent potential for characterizing nanoparticles in varied types of environmental samples.

Single-particle inductively coupled plasma–mass spectrometry (SP-ICP-MS) is an exciting new technique for detecting and characterizing metal nanoparticles at very low concentrations. It is fast and can provide significantly more information than other traditional techniques, including particle number concentration, particle size, and size distribution, in addition to the concentration of dissolved metals in solution. The added benefit of using ICP-MS is that it can distinguish between particles of different elemental compositions. The study will investigate the use of SP-ICP-MS to track the release of engineered nanoparticles (ENPs) into the environment and to better understand their fate and behavior specifically in drinking, surface, and wastewater samples.

The unique properties of engineered nanoparticles (ENPs) have created intense awareness in their environmental behavior. Because of the increased use of nanotechnology in consumer products, industrial applications, and healthcare technology, nanoparticles are more likely to enter the environment. For this reason, it is not only important to know the type, size, and distribution of nanoparticles in soils, potable waters, and wastewaters, but it is also crucial to understand their impact on the growing mechanism of crops used for human consumption. Therefore, to ensure the future development of nanotechnology products, there is clearly a need to evaluate the risks posed by these ENPs, which will require proper tools to fully understand their toxicological impact on human health. Current approaches to assess exposure levels include predictions based on computer modeling, together with direct measurement techniques. Predictions through modeling are based on knowledge of how they are emitted into the environment and by their behavior in the samples being studied. Although the life cycles of ENPs are now starting to be understood, very little is known about their environmental behavior. Prediction through life-cycle assessment modeling requires validation through measurement at environmentally significant concentrations. For ENPs that are being released into the environment, extremely sensitive methods are required to ensure that direct observations are representative in time and space. ENPs differ from most conventional ‘‘dissolved’’ chemicals in terms of their heterogeneous distributions in size, shape, surface charge, composition, and degree of dispersion. For this reason, it is not only important to determine their concentrations, but also these other important metrics, particularly when they are discharged and interact with their real-world surroundings.

Impact of Nanoparticles Released into the Environment

When nanoparticles enter the environment, they can undergo a number of potential transformations that depend not only on the properties of the nanoparticles but also on the medium they are being released into. These changes typically involve chemical and physical processes, but they can also involve biodegradation of surface coatings used to stabilize many nanomaterials. For example, the toxicity impact of nanomaterials on algae involves adsorption onto cell surfaces, which has the potential to disrupt transportation through the cell membrane. Additionally, larger organisms can directly ingest nanoparticles, and then enter the food chain when they are consumed by other aquatic and terrestrial forms of life. These processes are further complicated by aggregation of nanoparticles with other natural minerals and natural colloids, which will dramatically change their fate and potential toxicity in the environment.

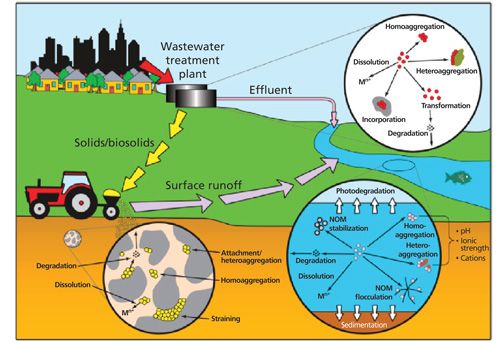

Nanomaterials from domestic, medical, and industrial sources may also undergo significant changes during wastewater cleaning processes, such as the conversion of silver nanoparticles to silver sulfide in treatment plants. In addition, aggregation of the nanomaterials with other minerals and organic matter in the wastewater often results in the nanomaterial combining with other solids in the effluent, rather than remaining as a dispersed nanoparticle suspension. So, apart from atmospheric deposition or accidental spillage of nanomaterials directly into rivers, lakes, and the surrounding land, wastewater treatment remains by far the largest source of nanomaterial contamination either from the runoff into groundwater sources and drinking water supplies or from the raw sewage sludge that is often spread onto the soil as a fertilizer (1).

Risk Assessment

Therefore, risk assessment for nanomaterial released into the environment is still evolving, and reliable measurements of environmentally significant concentrations remain challenging. Predicted environmental concentrations based on current usage are low, but they are expected to increase as the use of nanomaterials increases. At this early stage, comparisons of estimated exposure data with known toxicity data indicate that the predicted environmental concentrations are orders of magnitude below those known to have environmental effects on living plant and animal biota. As more toxicity data are generated under environmentally relevant conditions, risk assessments for nanomaterials will improve to produce accurate assessments that ensure environmental safety.

Many analytical techniques applied in materials science and other scientific disciplines could also be applied to ENP analysis. However, environmental and biological studies may require that methods be adapted to work at extremely low concentrations in complex matrices. The most pressing research needs are the development of techniques that introduce minimal artifacts to optimize sensitivity, specificity, and throughput, as well as differentiating between naturally occurring particles and manufactured nanoparticles, together with a better understanding of their dissolution properties.

Analytical Methodologies

The measurement and characterization of nanoparticles is therefore critical to all aspects of nanotechnology. In the field of environmental health, it has become clear that complete characterization of nanomaterials is important for interpreting the results of toxicological and human health studies. Metal-containing ENPs are a particularly significant class because their use in consumer products and industrial applications makes them the fastest growing category of nanoparticles (2).

Although many analytical techniques are available for nanometrology, only some can be successfully applied to environmental and health studies. Methods for assessing particle size distributions include electron microscopy, chromatography, laser light scattering, ultrafiltration, and field flow fractionation. However, the lack of specificity of these techniques is problematic for complex environmental matrices that may contain natural nanoparticles having polydisperse size distributions and heterogeneous compositions. For this reason, extremely sensitive detection techniques are needed if specific information about the elemental composition and concentration of the nanoparticles is required. Unfortunately, difficulties can also arise with some detection techniques because of a lack of sensitivity for characterizing and quantifying particles at environmentally relevant concentrations.

Role of ICP-MS

One technique that is proving invaluable for detecting and sizing metallic nanoparticles is single-particle inductively coupled plasma-mass spectrometry (SP-ICP-MS) (3). Its elemental specificity, sizing resolution, and unmatched sensitivity make it extremely applicable for the characterization of ENPs containing elements such as Ag and Au and compounds such as TiO2 and SiO2 that have been integrated into larger products such as consumer goods, foods, pharmaceuticals, and personal care products.

Much of the early work has focused on the use of ICP-MS with particle separation techniques, such as field flow fractionation and chromatography (4). However, more recently, SP-ICP-MS has shown a great deal of promise in several applications areas, including the determination of concentrations of silver nanoparticles in complex samples (5). This technique is suited to differentiate between the analyte in solution and existing as a nanoparticle without any prior separation techniques, simplifying nanoparticle analysis while eliminating complex sample preparation steps (6). This ability allows SP-ICP-MS to provide information on the size and size distribution of many varied and different metal-based nanoparticles, as well as the dissolved concentration of the analytes under study. Let’s take a closer look at the fundamental principle of SP-ICP-MS.

Fundamentals of SP-ICP-MS

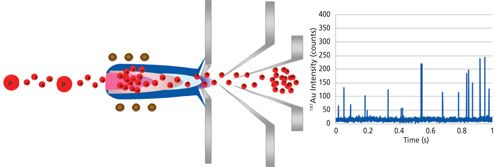

SP-ICP-MS is based on the measurement of the signal intensity produced by a single particle. Nanoparticle suspensions are sufficiently diluted to minimize the chances that more than one particle reaches the plasma at a time. The particle is atomized and ionized, producing a signal of relatively high intensity, which is measured as a pulse. This process is exemplified in Figure 1, which shows particles (P) and dissolved analyte in the sample aerosol entering the plasma and being ionized. The ions then pass through the interface region into the ion optics where they are eventually separated in the mass spectrometer. In this manner, particles are detected as individual pulses, whereas the dissolved analyte contributes to a continuous background signal. The frequency of pulses (events) provides the particle number concentration, whereas the intensity of each pulse is proportional to the mass of the nanoparticle. Because of the short transient nature of the pulse, very short integration times are necessary to maximize the detection of individual particles as pulses of ions after they are ionized by the plasma.

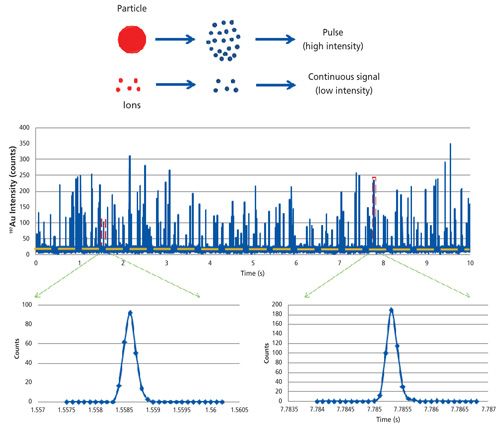

This process is exemplified in Figure 2, which shows both metal nanoparticles and metal ions in solution being ionized by an ICP-MS system. The signal from the dissolved ions is represented by the continuous signal below the dashed line, while the ionized pulses of nanoparticles are represented by the individual spikes. For this approach to work effectively, the speed of data acquisition and the response time of the detector must be fast enough to capture the time-resolved nanoparticle pulses, which are typically 300–400 µs (3). If the electronics are not fast enough, multiple or many pulses can easily pass through in a single integration window leading to inaccurate particle counting and sizing. For this application, the ICP-MS should be capable of using dwell times shorter than the particle transient signal time, thus avoiding false signals generated from clusters of particles. In practice, for an instrument that is optimized for nanoparticle characterization, this means using dwell times of 100 µs or less and a settling time of zero, so that the pulse can be fully characterized and precisely integrated using a peak area integration algorithm (7).

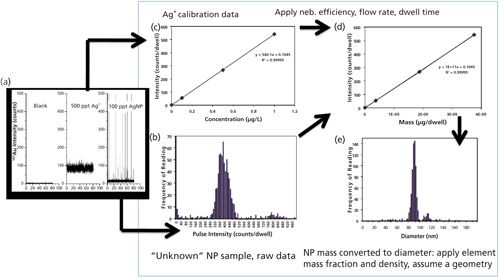

It is important to emphasize that ICP-MS is a mass-based technique, so in SP-ICP-MS, the particle size is determined by relating the pulse intensity to an elemental mass. With traditional ICP-MS analysis, the first step in this process is to create a calibration curve using dissolved standards. This curve connects the signal intensity from the instrument to the concentration of the analyte entering the plasma. The next step is to relate the concentration of the dissolved analyte to a total analyte mass that enters the plasma during each reading. This relationship between analyte concentration and the mass observed per event is called the mass flux, which is highly dependent on the transport efficiency of the sampling process and the instrument ion optics. This transport efficiency must be calculated for each instrument and under the given run conditions for the mass flux to be accurate. In this way, the resulting calibration curve relates signal intensity (counts/event) to a total mass transported into the plasma per event. So by using well-understood SP-ICP-MS principles, the intensity of each individual pulse (counts/event) can then be transformed using the mass flux calibration curve to determine the particle mass, which is easily converted to particle diameter, by knowing the density and assuming that the geometry (shape) of the particle is spherical (8,9). This is exemplified in Figure 3, which shows a signal of multiple gold nanoparticles over time (Figure 3a), with an individual pulse on the left-hand-side at the bottom (Figure 3b) and the dissolved ionic calibration curve on the top (Figure 3c). The top right-hand-side of Figure 3d shows the mass of the particle (in micrograms) per dwell time after nebulizer efficiency and flow rate have been applied. The mass of the nanoparticle is then converted to a diameter, based on the mass fraction and the density, based on the shape of the particle (Figure 3e) (10). Note: If the nanoparticle is rod-shaped (for example) a different calculation is used.

Now, let’s take a look at the real-world applicability of SP-ICP-MS by evaluating its capability and suitability for characterizing nanoparticles in environmental samples.

Real-World Applicability of SP-ICP-MS for Water Samples

Silver (Ag) nanoparticles are among the most commonly used nanoparticles in consumer products, such as fabrics, deodorants, and detergents because of their antimicrobial properties. Therefore, it is expected that Ag ENPs will find their way into the environment, necessitating ways to accurately and rapidly detect and characterize them in a variety of environmental matrices. Work has already been performed demonstrating the ability to successfully characterize Ag ENPs and their dissolution characteristics in a variety of drinking water (11), surface water (12), and wastewater samples (13). Let’s take a closer look at these three very different application requirements for SP-ICP-MS. Note: All the data presented in the following section were generated on a NexION 350D ICP-MS system using the Syngistix Nano Application Software Module (PerkinElmer Inc.) (14).

Drinking Water

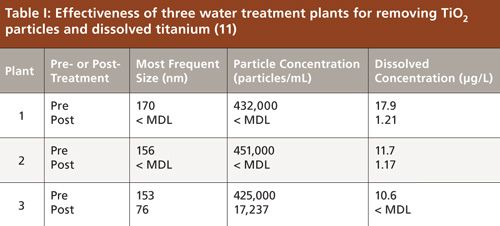

SP-ICP-MS is an ideal tool for assessing the efficiency of drinking water treatment systems in removing silver, gold, and titanium dioxide (TiO2) nanoparticles without using any other analytical technique. To evaluate the effectiveness of the water treatment process for these types of nanoparticles, Donovan and colleagues (11) collected water samples both pre- and post-treatment at three water treatment plants in Missouri. None of the six waters contained measurable amounts of Ag or Au, either as particles or dissolved species. However, all source water samples contained TiO2, as shown in Table I. Plants 1 and 2 effectively removed both dissolved Ti and TiO2 particles, as evidenced by the lower amounts present in the post-treatment waters than the pretreatment samples. The results from Plant 3 differed from the first two plants in that Ti-containing particles could still be detected after treatment, although significantly less than the pretreatment sample. However, all the dissolved Ti was removed.

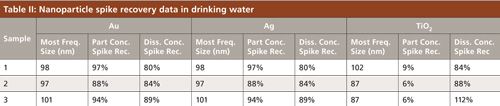

To check the accuracy of this method, spike recovery tests were performed for all metals, both as dissolved (Diss.) and particle (Part.) concentrations. Three samples were spiked with 2 μg/L of the dissolved metals and 100-nm nanoparticles at a concentration equal to 1 × 105 particles/mL. Table II shows the results of these spike recovery studies, which indicate accurate recoveries, except for the concentration of TiO2 nanoparticles, which recovered below 10% for each sample. Low recovery for TiO2 particles was most likely because of aggregation in the standards and in the water matrix. Without the addition of a surfactant, these uncapped TiO2 particles tended to aggregate, which resulted in particle loss between dilutions and in the water matrix where they had an opportunity to react and form new species or aggregate further and fall out of solution. The highest recovery obtained for these particles in ultra-pure water and in a surface water matrix were 24% and 9%, respectively.

Surface Waters

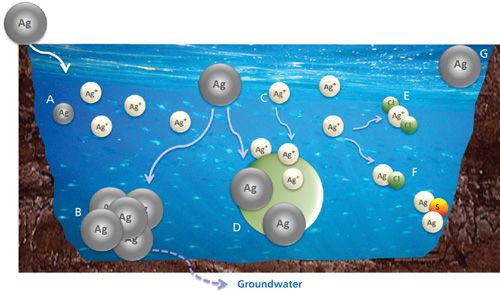

For this work, Hadioui and colleagues (12) investigated the efficiency of SP-ICP-MS for the detection and characterization of metal nanoparticles in fresh surface waters where they can be involved in various physicochemical processes as shown in Figure 4. In this example, dissolved silver (A), including released free Ag ions (C, D) and soluble complexes (E) can easily and instantly be measured by SP-ICP-MS. These dissolved species could also be determined by ultrafiltration followed by total metal quantification using ICP-MS or atomic absorption spectroscopy (AAS), but this procedure is time consuming since it requires the pre-equilibration of the membrane for at least three cycles of centrifugation, generally 20 min each (15). Aggregates (B) and remaining stable silver nanoparticles (G) can be counted and measured by other commonly used techniques such as nanoparticle tracking analysis (NTA), dynamic light scattering (DLS), and transmission electron microscopy (TEM), but SP-ICP-MS is the only method that can distinguish between nano-Ag (nAg) and other metal-based colloids in surface waters.

The surface water was sampled from a river in Montreal, Canada, and filtered with 0.2-μm filter paper before spiking with silver nanoparticles. Nano-Ag suspensions were added to water samples with concentrations ranging from 2.5 to 33.1 μg Ag/L and left to equilibrate under continuous and gentle shaking. Commercially available suspensions of gold and silver nanoparticles were used in this work. A National Institute of Standards and Technology (NIST) reference material (RM 8013) consisting of a suspension of gold nanoparticles (60 nm nominal diameter, 50 mg/L total mass concentration, and stabilized in a citrate buffer) was used to determine the nebulization efficiency, while two types of silver nanoparticle suspensions were used for the dissolution studies-a citrate-coated version (40 nm and 80 nm nominal diameter) and a noncoated version (80 nm nominal diameter). In addition, 60-nm nominal diameter Ag nanoparticles were used for quality control (QC) purposes.

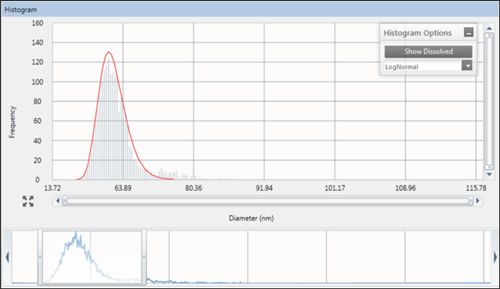

An interactive view of data acquisition of intensity as a function of time for the 60-nm nominal diameter silver nanoparticles is shown in Figure 5. In this example, the concentration of the analyte was 208 ng/L and was converted to volume and then into size knowing the density and the geometry of the particle using the Syngistix Nano Application Module, with no further need for manual data processing.

It is also important to emphasize that even after filtration of surface waters at 0.2 μm, the NTA method, which is commonly used for this type of analysis, showed the presence of quite significant amounts of colloidal particles with an average diameter of ~110 nm. Therefore, the addition of metal nanoparticles to this complex matrix would make their detection and characterization very difficult, if not impossible, with the commonly used techniques previously mentioned, such as DLS and TEM. Furthermore, even the determination of the dissolved fraction that is usually performed by ultrafiltration may be inadequate because silver ions may adsorb on the surface of the colloids and, therefore, be retained by the filtration membrane. Consequently, the proportion of dissolved metal will be underestimated. SP-ICP-MS measurements were found to be more effective and to have fewer limitations than other techniques. Indeed, the presence of other insoluble particles did not interfere with the analysis of silver nanoparticles, as the signal of Ag is recorded independently of the other constituent elements of the colloids.

The same group of researchers found that the SP-ICP-MS technique allowed the effective and selective measurement of changing particle size, aggregation, and dissolution over time at low concentrations. In fact, they concluded that SP-ICP-MS is probably the only suitable technique that can provide such information on the fate of metal nanoparticles at very low concentrations typically found in environmental waters (15).

Wastewater Samples

Another common, more complex matrix that must be evaluated for the determination of Ag ENPs is wastewater samples from wastewater treatment plants. The complexity and variety of the wastewater matrices can make the analysis of ENPs extremely challenging. Figure 6 is a representation of a wastewater treatment plant that shows the possible pathways that could introduce nanomaterials into the environment and the potential impact they might have on the surrounding land and water supplies (1).

A recently published study by Azodi and colleagues (13) evaluated the ability of SP-ICP-MS to characterize Ag ENPs in three common wastewater matrices: mixed liquor, effluent, and alginate solutions. The wastewater samples were collected from a wastewater treatment plant near Montreal, Quebec, Canada. The effluent wastewater was collected after the secondary settling tank, while the mixed liquor was collected after the secondary aeration tank. The effluent wastewater is the final treated wastewater that is discharged to the river from this treatment plant, while the mixed liquor is the wastewater that leaves the aeration tank after biological treatment to settle the suspended solids in the settling tank. As a result, the mixed liquor has much higher levels of suspended solids and a relatively higher dissolved carbon content compared to the effluent wastewater.

Alginate, more commonly known as alginic acid, is an anionic polysaccharide distributed widely in the cell walls of brown algae, which is present at parts-per-million levels in wastewaters and comprises the dissolved organic carbon fraction of wastewaters. The alginate solution was used as a known control-surrogate for comparison with the wastewater samples. All solutions were prepared using the alginic acid sodium salt from brown algae (at 6 ppm) in deionized water by shaking end-over-end for 1 h. Ag ENPs capped with polyvinylpyrrolidone (PVP) with a mean diameter of 67.8 ± 7.6 nm (as determined with TEM) were spiked into 10 mL of all samples at a concentration of 10 ppb (5 million particles/mL). The samples were then diluted 10–1000× with deionized water and sonicated for 5 min before analysis. All samples were prepared in triplicate. To determine the accuracy of SP-ICP-MS, the Ag ENPs were added to deionized water at a concentration of 0.1 ppb (50,000 particles/mL). The SP-ICP-MS measurement determined the mean size of the Ag ENPs to be 63.2 nm (which agrees with the TEM measurements), and the concentration to be 53,758 particles/mL, thus validating the accuracy of the measurements.

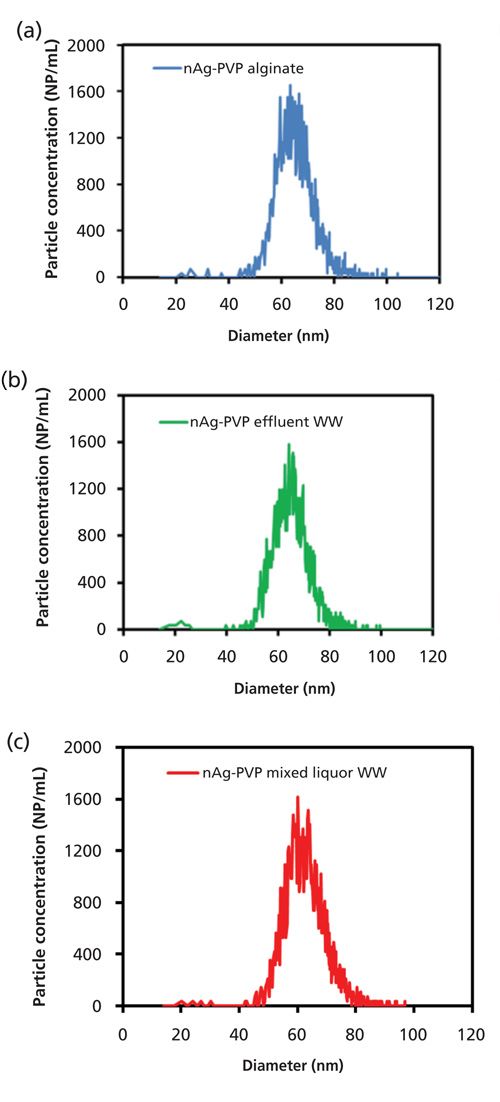

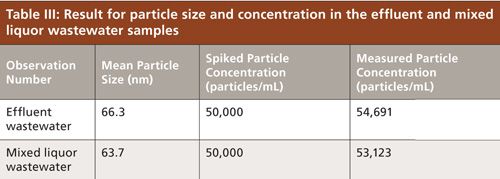

Next, the Ag ENPs were measured in a 6 ppm alginate solution. Once the accuracy of the technique was ensured, it was followed by the measurement of the effluent wastewater and mixed liquor samples. First, the total Ag concentration was measured in both wastewater samples and was found to range from 25 to 40 ppt, levels that should not inhibit the determination of Ag ENPs. Figure 7a shows the Ag particle size distribution for 0.1 ppb (50,000 particles/mL) in the alginate sample, which corresponds to a mean particle size of 66.1 nm, with a concentration of 52,302 particles/mL. The agreement between the measured and TEM-determined particle sizes indicates that the alginate matrix does not affect the measurement accuracy as exemplified in Figures 7b and 7c, which show the measured particle size distributions for the effluent and mixed liquor respectively. Table III shows the measured particle sizes of both samples that agree with the certificate value, together with particle concentrations, which are close to the calculated value, indicating that neither of the wastewater matrices impact the measurement and strongly suggesting that Ag ENPs can be successfully measured in wastewater samples.

Detection Capability

The detection limits for both the Ag particle size and concentrations in the wastewaters were also determined. For determining the particle size detection limits, the diluted samples were analyzed without any Ag ENPs being added. The detection limit was determined by running the unspiked wastewater matrices and observing the particle size, which corresponded to the smallest recorded peak. For the effluent, the detection limit was about 18 nm, while for the mixed liquor, it was about 12 nm. To determine the lowest concentration of Ag ENPs that could be detected, Ag ENPs were spiked into deionized water and diluted multiple times (Note: Since the wastewater matrices were shown not to affect the results, the detection limit was only measured in deionized water). The measured particle concentration was then recorded for each concentration. The particle concentration detection limit was determined to be the spiked particle concentration where the measured concentration did not change when the sample was diluted. In this work, the Ag ENP particle concentration detection limit was determined to be 25 ppt (12,500 particles/mL).

Final Thoughts

SP-ICP-MS demonstrates very exciting potential for the characterization of nanoparticles in many varied types of environmental samples. It is a very effective tool to assess the efficiency of drinking water treatment systems in removing certain nanoparticles, without the need for any additional techniques. It has also allowed the effective and selective measurement of changing particle size, aggregation, and dissolution over time at low concentrations in natural surface waters. Additionally, the technique has shown the versatility to measure and analyze nanoparticles in various matrices found in a wastewater treatment plant. There is no question that compared to other traditional analytical methods, SP-ICP-MS offers unique capabilities in tracking the fate and behavior of metal nanoparticles at extremely low levels in the environment. Although this study has focused on the effectiveness of the technique for the characterization of nanoparticles likely to be present in environmental water samples, it is also applicable to other types of metal and metal oxide nanoparticles in a variety of complex environmentally significant matrices including plant material (16) and biological tissue (17).

References

(1) G.E. Batley, J.K. Kirby, and M.J. McLaughlin, Acc. Chem. Res.46

(2) The Project on Emerging Nanotechnologies, “An Inventory of Nanotechnology-based Consumer Products Introduced on the Market,” available at: http://www.nanotechproject.org/cpi/.

(3) J.W. Olesik and P.J. Gray, J. Anal. At. Spectrom. 27, 1143 (2012).

(4) D.M. Mitrano, A. Barber, A. Bednar, P. Westerhoff, C.P. Higgins, and J.F. Ranville, J. Anal. At. Spectrom. 27, 1131–1142 (2012).

(5) D.M. Mitrano, E.K. Leshner, A. Bednar, J. Monserud, C.P. Higgins, and J.F. Ranville, Environ. Toxicol. Chem.31(1), 115–121 (2012).

(6) F. Laborda et al., J. Anal. At. Spectrom. 26(7), 1362–1371 (2011).

(7) A. Hineman and C. Stephan, J. Anal. At. Spectrom29, 1252–1257 (2014).

(8) A .C. Degueldre and P.Y. Favarger, Physicochem. Eng. Aspects217, 137–142 (2003).

(9) C. Degueldre and P.Y. Favarger, Colloids and Surfaces A: Physicochem. Eng. Aspects,217, 137–142 (2003).

(10) H.E. Pace, J. Rogers, C. Jarolimek, V.A. Coleman, C.P. Higgins, and J.F. Ranville, Anal. Chem.83(24), 9361–9369 (2011).

(11) A.R. Donovan, H. Shi, C. Adams, and C. Stephan, PerkinElmer Application Note, “Rapid Analysis of Silver, Gold, and Titanium Dioxide Nanoparticles in Drinking Water by Single Particle ICP-MS” (2015).

(12) M. Hadioui, K. Wilkinson, and C. Stephan, PerkinElmer Application Note, “Assessing the Fate of Silver Nanoparticles in Surface Waters Using Single Particle ICP-MS” (2014).

(13) M. Azodi, S. Ghoshal, and C. Stephan, PerkinElmer Application Note, “Measurement and Analysis of Silver Nanoparticles in Wastewaters with Single Particle ICP-MS” (2015).

(14) PerkinElmer Application Study, “Single Particle ICP-MS Syngistix Nano Application Module,” http://www.perkinelmer.com/catalog/product/id/N8140309.

(15) M. Hadioui, S. Leclerc, and K.J. Wilkinson, Talanta105, 15–19 (2013).

(16) Y. Dan, W. Zhang, X. Ma, H. Shi, and C. Stephan, PerkinElmer Application Note, “Gold Nanoparticle Uptake of Tomato Plants Characterized by Single Particle ICP-MS” (2015).

(17) E.P. Gray et. al., Environ. Sci. Technol.47(24), 14315−14323 (2013).

Chady Stephan is the manager of global applications of nanotechnology at PerkinElmer, Inc., in Woodbridge, Ontario, Canada. Robert Thomas is the principal of his own freelance writing and scientific consulting company, Scientific Solutions, based in Gaithersburg, Maryland. Direct correspondence to:

chady.stephan@perkinelmer.com

New Study Reveals Insights into Phenol’s Behavior in Ice

April 16th 2025A new study published in Spectrochimica Acta Part A by Dominik Heger and colleagues at Masaryk University reveals that phenol's photophysical properties change significantly when frozen, potentially enabling its breakdown by sunlight in icy environments.