40 Years Old and Still Solving Problems: Evolution of the ICP-MS Application Landscape

The year 2023 marks the 40th anniversary of the commercialization of inductively coupled plasma mass spectrometry (ICP-MS). Today, there are close to 2000 ICP-MS systems installed worldwide every year, representing around $400M in annual sales. These instruments are used for a wide variety of applications, from routine, high-throughput multielement analysis to more complex tasks, such as trace element speciation studies with high-performance liquid chromatography and monitoring of nanoparticles. My column this month will look at the evolving ICP-MS marketplace, highlighting current application trends (compared to other analytical spectroscopy techniques), and where the technique might be heading 5–10 years from now.

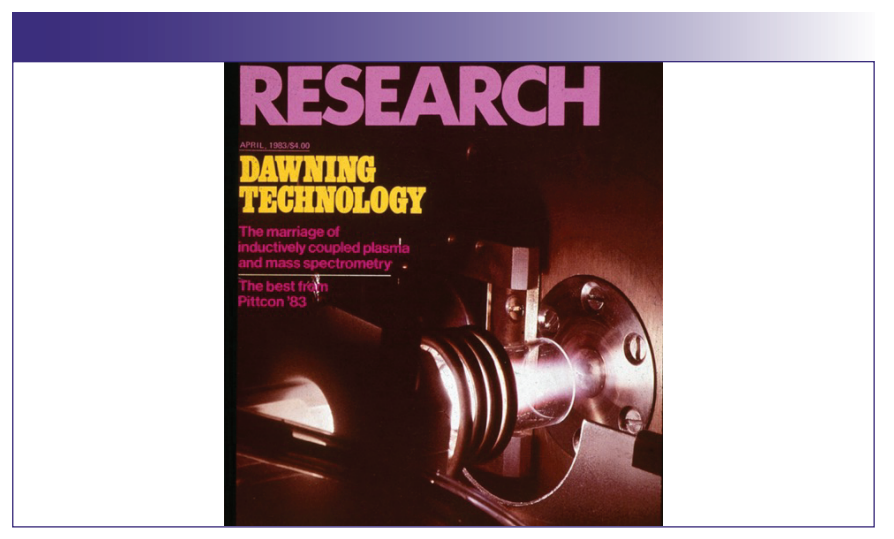

At the 1983 Pittsburgh Conference, SCIEX introduced the ELAN 250 quadrupole-based inductively coupled plasma (ICP) mass spectrometer (Figure 1). It would be another 12 months before its joint venture with PerkinElmer, Inc. was announced, but the event was the start of the meteoric rise of ICP-mass spectrometry (ICP-MS) as the dominant multielement technique used for ultra-trace elemental analysis, and the beginning of a competitive race which would see a number of other vendors and other mass spectrometer technologies come and go over the next 40 years.

FIGURE 1: 1983 Pittcon program announcing the introduction of the first commercial ICP-MS system. Printed with the permission of The Pittsburgh Conference.

Today, there are close to 2000 ICP-MS systems installed worldwide every year, representing around $400M in annual sales, performing a wide variety of applications, from routine, high-throughput multielement analysis to more complex tasks, such as trace element speciation studies with high-performance liquid chromatography and monitoring of nanoparticles (1). As more and more laboratories invest in the technique, the list of applications is getting significantly larger and more diverse.

In previous publications, I have given detailed information about the various ICP-MS application sectors being carried out by the user community (2). However, 40 years after the commercialization of the technique, it would be almost impossible to capture all of them. The most common ones include environmental monitoring, geochemical, metallurgical, petrochemical, petroleum, food, clinical, toxicology, semiconductor, industrial, energy, agricultural, nuclear, pharmaceutical, and cannabis, but every year it seems that a new market has woken up and realized the full potential of its capabilities. So, to celebrate the 40th anniversary of the technique, I have already begun working on the 4th edition of my ICP-MS textbook, “Practical Guide to ICP-MS: A Tutorial for Beginners,” which will be available in the early summer of 2023.

I cannot believe it has been almost 20 years since I published the first edition of the book in 2004, and 8 years since the 3rd edition was launched in 2014. But I have not been idle, as I have written two additional books since, one on elemental impurities in pharmaceuticals published in 2018, and the other on heavy metals in cannabis and hemp in 2021. What was originally intended as a series of ICP-MS tutorials on the basic principles for Spectroscopy Magazine in 2002 (3) quickly grew into a textbook focusing on the practical side of the technique. With over 6000 copies sold, including a Chinese (Mandarin) edition, I’m very honored that the book has gained the reputation as being the reference book of choice for novices and beginners to the technique all over the world. Sales have exceeded my wildest expectations.

However, this edition will be a little different, because, based on reader feedback, I have decided to also include fundamentals and applications of other complementary atomic spectroscopy (AS) techniques, including inductively coupled plasma optical emission spectroscopy (ICP-OES), flame and graphite furnace atomic absorption spectroscopy (FAAS/GFAAS), atomic fluorescence (AF), microwave induced plasma atomic emission spectrometry (MIP-AES), X-ray fluorescence (XRF), laser induced breakdown spectrometry (LIBS) and laser ablation, laser ionization time-of-flight mass spectrometry (LALI-TOF-MS). Moreover, to capture the staggering flexibility and capability of ICP-MS, the new book will also include a chapter dedicated to the continually evolving application landscape of the technique compared to other AS techniques. So, to give readers of Spectroscopy a flavor of the new book, particularly the ICP-MS marketplace, my AP column this month will highlight current application trends and where the technique might be heading 5–10 years from now.

Widespread Acceptability of ICP-MS

As a result of the widespread use and acceptability of ICP-MS, the cost of commercial instrumentation has dramatically fallen over the past 40 years. When the technique was first introduced, $250,000 was a fairly typical amount to spend, whereas today one can purchase a quadrupole or TOF system for under $150,000. Although it can cost a great deal more to invest in magnetic sector technology or a “triple quadrupole” collision/reaction cell instrument, most laboratories that are looking to invest in the technique should be able to justify the purchase of an instrument without price being a major concern. One of the benefits of this kind of price erosion is that, slowly but surely, the AA and ICP-OES user community are being attracted to ICP-MS, and as a result, the technique is being used in more and more diverse application areas. Figure 2 shows the approximate percentage breakdown of the major market segments being addressed by ICP-MS on a worldwide basis over the past 40 years (2).

FIGURE 2: Pie chart showing worldwide ICP-MS application market breakdown (2).

Three points should be emphasized here. First, these data can be significantly different on a geographical or regional basis, because of factors such as a country’s commitment (or lack of it) to environmental concerns or the size of a region’s electronics or nuclear industry, for example. Furthermore, many laboratories carry out more than one type of application, and as a result can be represented in more than one market segment. Finally, the research market segment has been listed as a separate category to show the instruments that are being used in an academic environment or for non-routine applications. However, many universities, federal organizations, or corporate R&D groups might be using their instrumentation for research purposes in a particular application segment. For these reasons, these data should only be considered an approximation for comparison purposes.

Application Capability

It’s fair to say that ultra-trace detection capability, combined with increased sample throughput, have been the main incentives for analytical chemists to invest in ICP-MS. The technique is now considered a mature tool that is being used for the routine, high-throughput analysis of complex samples with relatively seamless sample preparation procedures. In the early days, it was used by academic institutions and large corporate R&D laboratories. Nowadays, ICP-MS instrumentation is also being used by contract laboratories in the routine analysis of environmental, pharmaceutical, and biomonitoring applications, among others. This has been made possible by greater automation on the sample preparation side and seamless method development tools, which have resulted in far less operator expertise required to run them. It is also worth pointing out that stricter regulations are requiring lower and lower detection limits (DLs), particularly in the semiconductor, toxicology, and food market segments. In addition, for the past five years, the rapid growth in the cannabis industry has meant cultivators and processors have to ensure the safety of consumer products by meeting strict state-based limits for contaminants like heavy metals. So, the drive toward lower detection limits is just one factor, whereas the other is the analytical needs and demands of the customer. For example, the electronics industry is faced with the enormous challenge of “chasing zero,” so manufacturers must measure the lowest level of elemental impurities in process chemicals and electronic devices to ensure the highest performance of their products.

Challenges

As ICP-MS has become more applicable in a wide variety of application areas, it has become more readily accessible to startup laboratories. Part of this is the development of turnkey methods for food, environmental, biomonitoring, geochemical, pharmaceutical, and cannabis applications for inexperienced and novice users, which will be critical for the growth of this technique in these market segments.

Important considerations include ease of use, seamless software, low maintenance, and the ability to handle different matrices, which give the analyst confidence in the results being generated and ensure they get the correct answer the first time and every time. The user community expects these qualities, particularly in high-throughput laboratories. They want to run the instrument for extended periods with minimum maintenance and short downtime while simultaneously running multiple samples, many containing high concentrations of mineral acids. It is important to emphasize that this kind of sampling environment is not really instrument friendly. When samples are being run that contain >10% mineral acid or >10% dissolved solids, it will take its toll on the instrument’s sample introduction components. Therefore, the instrument must be rugged enough to handle this kind of sample matrix, without contributing significantly to the routine maintenance of the system, while at the same time delivering high quality data, day in and day out.

Therefore, ruggedness is critically important when designing an ICP-MS instrument. However, this is just one side of the analytical challenge. As mentioned previously, the semiconductor industry is the one application area where this kind of ruggedness is expected, but the lowest possible detection limits are also required. Just 15 years ago, 10 ppt was the guideline for elemental impurities in semiconductor process chemicals; today, the industry is requiring 1–2 ppt. This puts unique demands on the design of any instrument used for this kind of analysis.

Consequently, with the push for lower and lower detection capabilities, it is becoming a major challenge not only to develop instrumentation that has high analyte sensitivity and extremely low background noise, but also to have an ultra-clean laboratory and sample preparation environment that sets the stage for the detection of elements at such low levels. Both factors are absolutely critical. The trend towards ease of use has meant that operators have less time to be involved with the analytical procedure, and therefore are often not versed in the nuances of working in the ultra-trace environment and won’t necessarily recognize issues which require user intervention, should they arise. For that reason, instruments have to offer maintenance reminders that mitigate potential problems before they actually happen.

Regulations

The increasing demand for state-of-the-art ICP-MS equipment that offer practical solutions has been mainly driven by regulatory requirements. Whatever the industry, there’s a huge need for the detection of lower and lower impurities of inorganic pollutants like heavy metals. For example, many regulations require the testing of soil for toxic metals before any crops can be grown in the soil. In addition, industrial effluent must be regulated to know what is being discharged into waste streams. This is particularly the case with nanomaterials, which are finding their way into the environment. Experts have not extensively studied the long-term impact of inorganic nanoparticles on plants and animals, so going forward, industry clearly must have a much better understanding of this issue.

Another example is the mining of minerals such as titanium dioxide, which is used as a whitening agent and silicon dioxide, used for its drying and anti-caking properties in the manufacture of pharmaceutical excipients, fillers and tablet binders. There are new regulations that require manufacturers to measure 24 elemental impurities at the microgram (µg) level in their products. If they do not comply with these permitted daily exposure (PDE) limits, they could be liable for significant fines or even the closure of their manufacturing plant. So, there are clearly many roles in which metals play a critical role in the world we live in, and, as a result, the quantification and regulation of these metals and metalloids is required. Hence the importance of using very sensitive techniques like ICP-MS as well as performance and productivity enhancing accessories to help us carry out those extremely low measurements.

Application Trends

There are two major trends to address those needs. One is at the high end, where the semiconductor and the biomonitoring markets are chasing after the lowest detection limits, being able to analyze as many inorganic analytes as possible. This is where you see significant research being carried out to develop offerings with the lowest detection limits, maximum interference reduction, and optimum flexibility—in other words, the highest-performance instruments. A separate trend involves the routine analysis of food, environmental, pharmaceutical, and cannabis related samples, for which ICP-MS sensitivity is already sufficient to meet their requirements. For these laboratories, the trend is toward improved robustness, less routine maintenance, more seamless integration with automated sampling solutions and ease of use, which is clearly a very different application segment from ultra-low background levels and detection capability.

Factors Impacting ICP-MS Instrumental Development?

Since many academic groups are not developing hardware intended for commercialization these days, the trend in these institutions seems to be focused more on application development. This is in contrast to the 1970s and 1980s, when, for example, the fundamentals of ICP-MS research were carried out predominantly in academia. However, more recently, we have seen a shift toward ICP-MS development being carried out mostly by manufacturers, and much of the cutting-edge application work being carried out or supported by academia. A good example of this is the expansion of ICP-MS into the field of nanomaterials, and specifically detecting nanoparticles in environmental and biological samples over the past four to five years. Here there have been several excellent collaborations occurring between universities and manufacturers. In general, there is an increased interest from universities to expand into niche application areas that are not necessarily being addressed by vendors or other users such as single particle and single cell analysis to monitor the metal content within single cells to better understand the mechanism of how metals such as platinum play a role in cancer treatment research.

Another example is in the pharmaceutical industry, where USP Chapters <232 >, <2232> and <233> and ICH Q3D Guidelines have opened up new markets for ICP-MS through recent regulations for elemental impurities testing in drug products and dietary supplements. An extension of this application is the testing of cannabis and cannabinoid consumer products for heavy-metal contaminants known as the Big Four—lead (Pb), cadmium (Cd), arsenic (As), and mercury (Hg)—using regulations initiated by the pharmaceutical industry. However, unlike the manufacture of drugs, there is no real tracking of the sources of heavy metals in cannabis, so it is not uncommon to see product recalls because of elevated levels of elemental contaminants. As a result of this, it has become critical to monitor the cannabis plants and products for a wider panel of elemental contaminants than the Big Four and to include others that are worthy of consideration using ICP-MS. Again, this is clear indication that some application sectors are being stimulated by the demands of the industry and supported and driven by the manufacturers, as opposed to coming from university-directed research.

Future Direction and Final Thoughts

Instrument vendors are firmly committed to the ICP-MS marketplace, with sales growing at approximately 6% per year (compared to about 3% for ICP-OES). If we look at the main market segments, such as semiconductor, biomonitoring, environmental, geological, industrial, food, pharmaceutical, and cannabis, it is clear that demand for ICP-MS is still growing rapidly. This growth is achieved mainly by collaborating with key market-driven customers to ensure that they are addressing their future needs, and using this feedback to help them design innovative products, whether related to application development, hardware improvements, or software enhancements. The aim of this article has therefore been to give the reader a snapshot of the ICP-MS application landscape, and a better understanding of why it is still the fastest growing trace element technique available today. If there is one common theme that runs through many of these applications, it is the unparalleled detection limits the technique has to offer, for both the total and speciated form of the element. When this is combined with its rapid multielement characteristics, isotopic measurement capability, freedom from interferences, and ease of use, it is clear that ICP-MS will continue to dominate the application landscape above all other AS techniques.

References

(1) Global ICP-MS System Market Research Report 2022 (Industry Research, Pune, India). https://www.industryresearch.biz/global-icp-ms-system-market-21299553

(2) Practical Guide to ICP-MS: A Tutorial for Beginners; (CRC Press, Boca Raton, FL, 3rd ed., 2014). https://www.routledge.com/Practical-Guide-to-ICPMS-A-Tutorial-for-BeginnersThird-Edition/Thomas/p/book/9781466555433#

(3) Beginners Guide to ICP-MS, Spectroscopy Magazine Tutorial Series, 2002, http://www.scientificsolutions1.com/Beginners%20guide%20to%20ICP-MS.pdf

Robert Thomas, the editor of the "Atomic Perspective" column, is the principal of Scientific Solutions, a consulting company that serves the educational and writing needs of the trace element analysis user community. Rob has worked in the field of atomic spectroscopy and mass spectrometry for more than 45 years, including 24 years for a manufacturer of atomic spectroscopic instrumentation. He has authored more than 100 scientific publications, including a 15-part tutorial series, "A Beginners Guide to ICP-MS." In addition, he has authored five textbooks on the fundamentals and applications of ICP-MS. His most recent book, a paperback edition of Measuring Heavy Metal Contaminants in Cannabis and Hemp was published in Decemeber, 2021. Rob has an advanced degree in analytical chemistry from the University of Wales, UK, and is a Fellow of the Royal Society of Chemistry (FRSC) and a Chartered Chemist (CChem). Direct correspondence to SpectroscopyEdit@mmhgroup.com.

AI Shakes Up Spectroscopy as New Tools Reveal the Secret Life of Molecules

April 14th 2025A leading-edge review led by researchers at Oak Ridge National Laboratory and MIT explores how artificial intelligence is revolutionizing the study of molecular vibrations and phonon dynamics. From infrared and Raman spectroscopy to neutron and X-ray scattering, AI is transforming how scientists interpret vibrational spectra and predict material behaviors.

Laser Ablation Molecular Isotopic Spectrometry: A New Dimension of LIBS

July 5th 2012Part of a new podcast series presented in collaboration with the Federation of Analytical Chemistry and Spectroscopy Societies (FACSS), in connection with SciX 2012 — the Great Scientific Exchange, the North American conference (39th Annual) of FACSS.

Advancing Corrosion Resistance in Additively Manufactured Titanium Alloys Through Heat Treatment

April 7th 2025Researchers have demonstrated that heat treatment significantly enhances the corrosion resistance of additively manufactured TC4 titanium alloy by transforming its microstructure, offering valuable insights for aerospace applications.

New Multi-Spectroscopic System Enhances Cultural Heritage Analysis

April 2nd 2025A new study published in Talanta introduces SYSPECTRAL, a portable multi-spectroscopic system that can conduct non-invasive, in situ chemical analysis of cultural heritage materials by integrating LIBS, LIF, Raman, and reflectance spectroscopy into a single compact device.