EDXRF Analysis of Coal by FP Method

Application Notebook

The analysis of coal is demonstrated, with specific emphasis on the measurement of Na2O, using a Cartesian geometry energy dispersive X-ray fluorescence (EDXRF) spectrometer employing the Fundamental Parameters (FP) approach.

The analysis of coal is demonstrated, with specific emphasis on the measurement of Na2 O, using a Cartesian geometry energy dispersive X-ray fluorescence (EDXRF) spectrometer employing the Fundamental Parameters (FP) approach.

During the mining, processing, and burning of coal, process monitoring and control are vital to the efficiency and quality of the final product. Whether screening incoming raw materials, monitoring production processes, or QA/QC out-processing, a fast, simple, and accurate method for analyzing samples is important throughout the production cycle. Specific attention is often given to the sodium content (Na2O). High sodium content can combine with sulfur or aluminum and silicon to form sodium sulfate or sodium alumina-silicate compounds. Such compounds, formed when burning high sodium coals, can lead to fouling of the cyclone or heat exchange surfaces. Cartesian geometry EDXRF spectrometry is demonstrated to meet the challenge of analyzing low sodium coals.

Experimental

Known (previously assayed) coal samples were ground, using a ball mill, to a homogeneous dry powder of <200 mesh (~75 µm grain size). The powder was then converted into a pellet using a hydraulic press at 20 tons pressure. Measurements were made, under vacuum conditions, using a Rigaku NEX CG Cartesian geometry EDXRF spectrometer (see Figure 1) equipped with polarization and secondary excitation targets. Total analysis time was 1400 s per sample.

Figure 1: Rigaku NEX CG EDXRF spectrometer.

Results

Results presented were based on the proprietary Fundamental Parameters (FP) software package developed for the Rigaku NEX CG Spectrometer. The RPF-SQX pellet FP template uses an advanced "scattering FP" program that automatically deconvolutes spectral peaks and models the sample matrix using fundamental X-ray fluorescence (XRF) equations.

The scattering FP template was chosen to estimate and better model the non-measureable components of the sample matrix (H to F) by utilizing the ratio of Compton/Thomson scatter to determine the average atomic number (Z) of the matrix. This approach provides an estimate of the percentage of the sample that cannot be measured and yields more accurate analytical results for the remaining elements that can be measured, affording a semi-quantitative measurement of elemental concentrations without the need for a large suite of known (assayed) calibration standards.

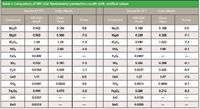

Table I: Comparison of RPF-SQX fundamental parameters results with certified values

Supplementing the core FP method, a matrix-specific Matching Library was employed, using three assayed field samples, to further improve analytical results. Matching Libraries are easy to create and are often used in conjunction with the standard FP library to better model any given matrix so as to improve the result quality. As shown in Table I, excellent agreement with the reference materials — within 10% relative — was achieved. Repeatability of the method is demonstrated in Table II.

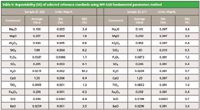

Table II: Repeatability (5X) of selected reference standards using RPF-SQX fundamental parameters method

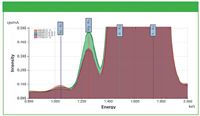

Using the total analysis time of 1400 s, precision shows the typical lower limit of detection (LLD) for Na2O is ≤0.05%, depending on the concentration of other elements in the coal. A count time of 1000 s was used for the Light Element Optimization target (see Figure 2) and the measurement of Na2O. The four other excitation targets, used to complete the analysis, each employed a 100 s count time. When Na2O is not important in the analysis, a shorter total analysis time of 400–500 s may be used.

Figure 2: Illustration of the light element (low-Z) sensitivity achieved with Light Element Optimization (LEO) secondary target excitation.

Conclusion

The Rigaku NEX CG Cartesian geometry EDXRF spectrometer, using the RPF-SQX fundamental parameters method coupled with a simple to create 3-point Matching Library, affords excellent performance for the elemental analysis of coal. Using the Light Element Optimization (LEO) secondary excitation target, optimum measurement of Na2O is achieved. The use of RPF-SQX greatly decreases, or even eliminates, the need for large suites of calibration standards. An advanced X-ray optical design, coupled to a novel and very advanced FP algorithm, delivers state-of-the-art performance appropriate for routine quality control (QC) applications. The results shown demonstrate that the Rigaku NEX CG is an excellent tool for the elemental analysis of coal.

Applied Rigaku Technologies, Inc.

9825 Spectrum Drive, Bldg. 4, Suite 475, Austin, TX 78717

tel. (512) 225-1796, fax (512) 225-1797

Website: www.RigakuEDXRF.com

Enhancing Trace Element Analysis with Inductively Coupled Plasma Mass Spectrometry

May 15th 2025Elemental analysis is crucial in a wide variety of applications from detecting toxic elements within the environment, to ensuring drinking water is safe for human consumption, to food product safety. ICP-MS—able to measure an atom’s mass—offers low detection limits in the range of parts per trillion (ppt), making it a widely used method that can detect toxic elements well below regulatory limits. This paper expands upon how new ICP-MS technology can meet the challenges associated with heightened demands for element analysis and the hurdles laboratories face when analyzing high-matrix samples.

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)

.png&w=3840&q=75)