Integrated Analysis of In-Service Lubricants for Particle Size and Count and Metal Content in a Single Sample Run

By placing a liquid particle counter in-line with an ICP-OES system it is possible to analyze wear metals and particles in lubricant samples in one run. This approach streamlines the monitoring of in-service lubricants and meets the ASTM D5185 standard. Such analyses are critical for heavy machinery maintenance.

Preventative maintenance is critical to keeping heavy equipment on the job for construction, mining, and more industries around the globe. Proactive testing and analysis of in-service lubricants and key fluids can play a key part. This article discusses adding a liquid particle counter in-line with an ICP-OES system to analyze wear metals and particles in lubricant samples in one run, with a single sample preparation, an innovative approach for streamlining the monitoring of in-service lubricants and meeting ASTM D5185 standards.

Globally, heavy machinery is one of the most important pieces of equipment used in construction, mining, and a variety of other industries. As the scale of these operations increases, the size, complexity, and cost of the equipment also increases. As a result, breakdowns of heavy machinery can be costly, both in productivity and revenue loss from downtime, as well as in equipment repair bills.

To help combat this, preventive maintenance has become paramount,and a key area of preventive maintenance includes monitoring the quality of the lubricants and key fluids used in heavy machinery. With this, lubricants such as hydraulic fluids, gear oils, and transmission fluids are directly sampled from different parts of the equipment over time. These samples can then be analyzed via a variety of tests, one of which includes the quantification of key wear metals. Here, an elemental profile is tracked for specific metals of interest, and the trends are used to indicate when an oil or fluid may need to be changed. Additionally, the wear metal concentration can identify the status of a component, where increases in key analyte concentrations may indicate maintenance is required.

Meeting D5185

Because the analysis of oil as a diagnostic for engine maintenance is so common, the American Society of Testing and Materials (ASTM) created a method specifically addressing this analysis, D5185 (1), also known as the “Standard Test Method for Multielement Determination of Used and Unused Lubricating Oils.”

When monitoring wear metals in oils, typical concentrations which serve as diagnostics are about 1 ppm, making inductively coupled plasma optical emission spectroscopy (ICP-OES) the preferred analytical technique, due to its speed, matrix tolerance, and ability to easily and accurately measure these concentrations (1,2). The ASTM method D5185 adheres to strict standards to ensure data quality. However, many labs run the D5185 process with hundreds of samples a day, making strict adherence to the method a burdensome task (3).

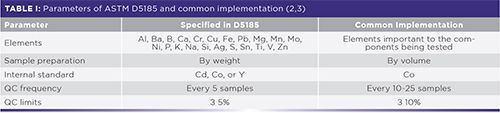

To help address this, creating minor modifications to the sampling and testing approach and process can make labs more time efficient, while also maintaining data integrity. For example, simply changing the frequency of when a quality control check is analyzed or adjusting the quality control limits can make a positive impact. Table I shows several parameters, along with their specifications in D5185 and common implementations.

Enter Particle Count Analysis

Additionally, particle count analysis is proving to be an important diagnostic tool for lubricant condition monitoring and maintenance programs. While the impacts of particle size and concentration are becoming better understood, lubricant test methods continue to expand in their ability to measure and identify particulate information. Examination of particle contamination has, for example, helped to identify root causes of mechanical wear. As a result, the use of cleaner fluids is being recommended to maintain reasonable levels of wear. Generally, the “dirtier” the oil, the more quickly it can cause wear and part failure. Particle counting identifies the number of particles per volume of sample for a given particle size. For lubricants, an increase in particle count can be a diagnostic for component failure; high levels of contaminants can cause filter blockages and hard particles can have a serious impact on the life of pumps, pistons, gears, bearings, and other moving parts by accelerating wear and erosion (4).

Traditionally, particle counting is done as a stand-alone analysis using pore blocking or light extinction. In short, these two are both nondestructive flow through techniques. Since the measure and monitoring of particle count is becoming more routine, ASTM developed methods regarding this analysis, such as D7647 (4), the “Standard Test Method for Automatic Particle Counting of Lubricating and Hydraulic Fluids Using Dilution Techniques to Eliminate the Contribution of Water and Interfering Soft Particles by Light Extinction,” and D7619 (5), the “Standard Test Method for Sizing and Counting Particles in Light and Middle Distillate Fuels, by Automatic Particle Counter.” In-service oils and other lubricants are monitored for particle size similarly to how they are monitored for elemental concentration. While there are a variety of national standards for coding and sizing, the most widely used are those established by the International Organization for Standardization (ISO). ISO 4406 (6) has established a list of codes categorizing particle count in terms of ranges. Samples are measured by the number of particles per unit volume to get the concentration of particles. Particle count concentrations can become large quickly and dealing with such large numbers for thousands of samples can become overwhelming. By assigning a number based on a set range of concentrations, interpretation of the results can be simplified using the ISO coding system.

As previously mentioned, traditional particle counters are used as stand-alone analyses, often involving a time-consuming, hands-on analysis where a technician loads and measures each sample manually. Because particle counting is becoming more routine for lubricant condition monitoring, labs are looking for more efficient ways to analyze their samples.

This application discusses the hyphenation of an in-line particle counter to an ICP-OES sampling system, operating between the autosampler and the ICP nebulizer, allowing for particle count and elemental analysis to be attained in one analysis (7). The sample introduction system is key to the success of this application, utilizing a dual homogenizing autosampler that stirs each sample prior to analysis.

Many labs following method D5185 are high-throughput environments looking to minimize overall sample-to-sample analysis time. During the analysis process of in-service oil samples, sample uptake and washout require more time than the actual measurement time. Therefore, anything that reduces sample uptake and washout without reducing data quality is valuable. With this goal in mind, while the sample loop is being filled for ICP analysis, particle counting is taking place. This arrangement provides several benefits to particle counting by performing the measurements on diluted lubricants while maintaining the integrity of the ICP analysis, including:

- High sample throughput for particle counting

- Two analyses in one run with a single sample preparation

- Small footprint to save laboratory bench space

- Smaller sample size for particle counting.

Experimental

Samples and Sample Preparation

In-service lubricant samples were prepared by diluting 1:10 (w/w) with an ultra-low particulate solvent, which consisted of a refined kerosene that had been prefiltered to ensure low background counts of particles. The solvent was also pre-spiked with cobalt (Co) at 40 ppm, serving as an internal standard to correct for sample transport variations and matrix differences in the ICP analysis. Adding the internal standard into the diluent is the fastest, most accurate way to equally add it to all standards and samples. Since the samples were also analyzed for particle content, it was crucial that the solvent chosen was free of particles to a level capable of supporting particle count results at the desired ISO codes. To provide the lowest level of background contamination, the solvent used must meet a cleanliness requirement for low baseline results for the >4, >6, and >14 μm particle sizes.

Instrumental Conditions

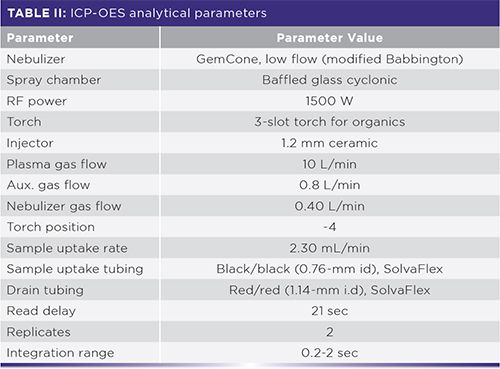

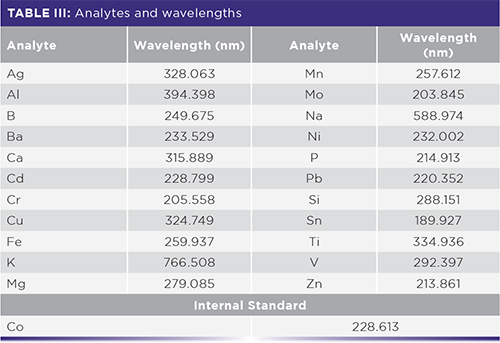

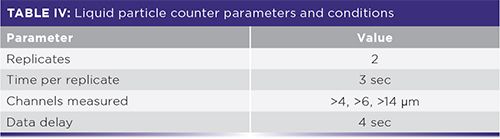

All analyses were performed with a PerkinElmer Avio 500 ICP-OES, coupled with an LPC 500 particle counter, using the conditions in Tables II, III and IV, respectively. ICP quantitative measurements were made against external calibration curves prepared from three 23-element oil stock solutions (V-23) at 50, 100, and 500 ppm, along with a metals additive oil standard (MA4), containing Ca at 5000 ppm and Mg, P and Zn at 1600 ppm each. The blank for the ICP results was 75 cST base oil. The QC standards consisted of the 50 ppm standard for all wear metals and the MA4 standard for the additive elements.

The particle counter is calibrated at the factory in accordance with ISO 11171(8). Recalibration is recommended once every six months with a secondary reference standard. A verification fluid for particle counting/sizing can be analyzed periodically to verify the accuracy of the sensor calibration.

Results and Discussion

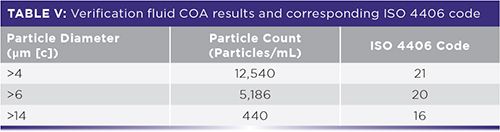

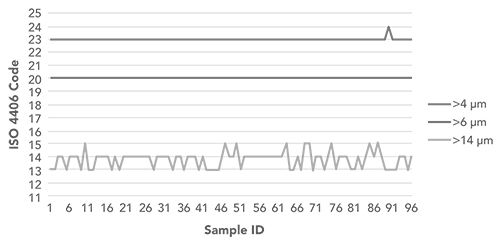

To assess the accuracy and stability of the particle counter, a reference fluid was analyzed periodically throughout an 8 h analysis of in-service oils. Table V shows the expected particle counts per mL from the certificate of analysis (COA), along with the corresponding ISO 4406 code for >4, >6 and >14 μm sizes, while Figure 1 shows the results of the analysis, thus indicating that all results are within ± 1 ISO code over the eight hours.

Figure 1: Verification fluid particle counting results: Analysis of the verification fluid over a period of 8 hours of in-service oils shows the accuracy and reliability of the particle counter, where expected results for sizes >4, >6, >14 μm are within ± 1 ISO code.

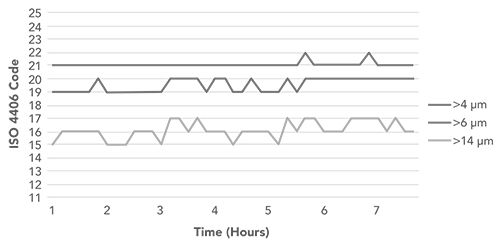

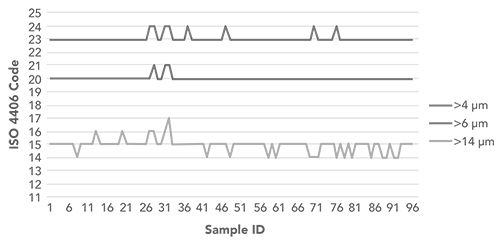

To assess stability of the particle counter with real samples, used composite transmission and composite gear oil samples were split into 96 aliquots for measurement. The results of these analyses appear in Figures 2 and 3, demonstrating the stability of the particle counting results in real samples, as variations of ± 1 ISO code were observed.

Figure 2: Transmission sample particle counting results: Analysis of used transmission oil composite shows the repeatability of the particle counter, where results for sizes >4, >6, >14 μm are within ± 1 ISO code, except for one instance for size >14 μm.

Figure 3: Gear sample particle counting results: Analysis of used gear oil composite shows the repeatability of the particle counter, where results for sizes >4, >6, >14 μm are within ± 1 ISO code.

Particle data acquisition performed well, meeting the requirements of the system by producing results within ± 1 ISO code.

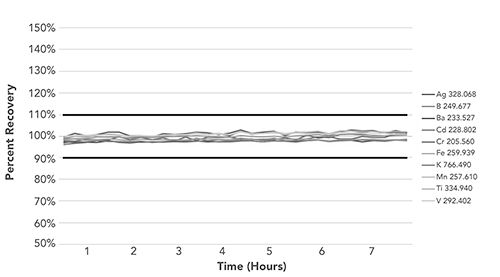

In order to further qualify the validity of this hyphenated application, elemental analysis by ICP was monitored simultaneously with particle count data acquisition, shown in Figure 1. While analyzing over 500 in-service lubricant samples for particle count and size, wear metal analysis was also performed, and quality control samples were tracked. The analysis of the 50 ppm (V-23) QC, shown in Figure 4, was within ± 10% recovery.

Figure 4: Stability of wear metals analysis of 50 ppm (V-23) quality control standard over the course of an eight-hour analytical run of 576 in-service oil samples, with in-line particle count data acquisition (50 ppm QC percent recovery).

There is no compromise in data quality for the ICP-OES wear metal analysis. With the integration of a liquid particle counter, the results demonstrate the robustness and stability of the ICP-OES system in alignment with ASTM D5185.

Conclusion

With heavy machinery, it is important to assess the status of its oil or lubricants during operation to prevent breakdowns and costly repairs. If the oil degrades too much or becomes highly contaminated, it can damage various components. An increase in particle count, combined with an increase in concentration of key wear metals, provides important diagnostic information that leads to decisions involving maintenance. By adding a liquid particle counter in-line with an ICP-OES system, lubricant samples can be analyzed for both wear metals and particles in one run, with a single sample preparation. With less than 1 mL of sample, an average analysis time of 45 seconds sample-to-sample was achieved for the acquisition of both ICP and particle counting and sizing analyses, compared to the traditional consumption of 20-30 mL of sample with over 5 min of analysis time. Most importantly, it has been shown that the integration of these two analyses into one run gives accurate and stable results for both particle counting and elemental analysis according to ASTM D5185.

References

- ASTM D5185,Standard Test Method for Multielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry, American Society of Testing and Materials (ASTM), West Conshohocken, Pennsylvania.

- D. Hilligoss, “Analysis of In-Service Oils Following ASTM D5185 with the Avio 500 ICP-OES”, PerkinElmer Application Note, 2017.

- D. Hilligoss, “Analysis of In-Service Oils Following ASTM D5185 with the Avio 200 ICP-OES”, PerkinElmer Application Note, 2016.

- ASTM D7647-10, Standard Test Method for Automatic Particle Counting of Lubricating and Hydraulic Fluids Using Dilution Techniques to Eliminate the Contribution of Water and Interfering Soft Particles by Light Extinction, American Society of Testing and Materials (ASTM), West Conshohocken, Pennsylvania.

- ASTM D7619-17, Standard Test Method for Sizing and Counting Particles in Light and Middle Distillate Fuels, by Automatic Particle Counter, American Society of Testing and Materials (ASTM), West Conshohocken, Pennsylvania.

- ISO 4406, Hydraulic Fluid Power-Fluids-Method for Coding Level of Contamination by Solid Particles, International Organization of Standardization (ISO), Geneva, Switzerland.

- A. Wassmuth, R. Forester, and S.Smith, “Single Particle Optical Sizing and ICP-OES”, PerkinElmer Application Note, 2019.

- ISO 11171, Hydraulic fluid power – Calibration of automatic particle counters for liquids, International Organization of Standardization (ISO), Geneva, Switzerland.

Robert Thomas is principal of Scientific Solutions, a consulting company that serves the application and writing needs of the trace element user community. He has worked in the field of atomic and mass spectroscopy for more than 40 years and has written over 100 technical publications including a 15-part tutorial series on ICP-MS. He recently completed his fourth textbook entitled Measuring Elemental Impurities in Pharmaceuticals: A Practical Guide, and is currently working on his next book project which focuses on heavy metals in cannabis and hemp. He has an advanced degree in analytical chemistry from the University of Wales, UK, and is also a Fellow of the Royal Society of Chemistry (FRSC) and a Chartered Chemist (CChem).

Katelyn Hasme is an Industrial Application Scientist at PerkinElmer, Inc., in Shelton, Connecticut.

Autumn Wassmuth is an Associate Product Leader, ICP-OES, at PerkinElmer, Inc., in Shelton, Connecticut.

Applications of Micro X-Ray Fluorescence Spectroscopy in Food and Agricultural Products

January 25th 2025In recent years, advances in X-ray optics and detectors have enabled the commercialization of laboratory μXRF spectrometers with spot sizes of ~3 to 30 μm that are suitable for routine imaging of element localization, which was previously only available with scanning electron microscopy (SEM-EDS). This new technique opens a variety of new μXRF applications in the food and agricultural sciences, which have the potential to provide researchers with valuable data that can enhance food safety, improve product consistency, and refine our understanding of the mechanisms of elemental uptake and homeostasis in agricultural crops. This month’s column takes a more detailed look at some of those application areas.