FT-IR Sampling of Residues on Curved Metal Surfaces Outside of the Sampling Compartment

In the manufacturing process, it frequently becomes important to determine if metal parts are clean or are sufficiently lubricated with oil. Infrared analysis of small, flat pieces can be readily carried out by in-compartment grazing angle specular reflectance.

Susan Berets and Jeffrey Christenson, Harrick Scientific Products, Inc.

In the manufacturing process, it frequently becomes important to determine if metal parts are clean or are sufficiently lubricated with oil. Infrared analysis of small, flat pieces can be readily carried out by in-compartment grazing angle specular reflectance. However, parts are frequently large and irregularly shaped or curved, which makes in-compartment analysis trickier. This note explores the use of a specular reflectance fiber optic probe to measure oil on the curved surface of a large metal cylinder outside of the spectrometer sampling compartment.

Experimental

The measurements were carried out using Harrick Omni-Spec fiber optic specular reflectance probe with two PIR fibers (Figure 1), interfaced to a commercial FT-IR spectrometer through the Harrick FiberMate2 coupler. Spectra were collected at an 8 cm-1 resolution and signal averaged over 32 scans with an MCT-A detector. The sample investigated was a stainless steel cylinder, 6 in. in diameter and 4.5 in. high, with a machined finish. The sample was cleaned for the background measurement and a thin coating of Mazola oil was applied to the same area prior to the sample measurement. For both the sample and background measurements, the Omni-Spec was held so its sampling surface was tangential to the surface of the sample.

Figure 1: Omni-Spec specular reflection fiber optic probe.

Results and Discussion

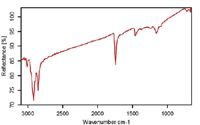

Figure 2 shows the oil coated metal. As expected, there are C-H stretching bands prominent in the 2800–2900 cm-1 region, in addition to bands at 1724 cm-1 due to a C=O stretch, 1462 cm-1 due to C-H bends, and 1160 cm-1 from a C-O stretch. Note that there is increased noise about 3000 cm-1 . This is due to the optical cut-off of the PIR fiber. The baseline of the spectrum is also strongly sloped. This is due the machine finish on the sample which creates shiny and rough areas on the surface. The Omni-Spec collects the specular reflectance in addition to some fraction of the diffused specular reflectance. This combination results in a sloping baseline.

Figure 2: Specular reflectance spectrum of oil on surface of machined steel cylinder.

Conclusion

Specular reflection fiber optic probes such as the Omni-Spec can be used effectively to examine coatings and residues on large, curved metal surfaces, provided that care is taken in positioning the probe relative to the sampling surface. The Omni-Spec fiber optic probe operates outside of the spectrometer sample compartment, making it a useful tool for examining large samples.

Harrick Scientific Products, Inc.

141 Tompkins Ave., Box 277, Pleasantville, NY 10570

tel. (914) 747-7202, fax (914) 747-7409

Website: www.harricksci.com

AI Shakes Up Spectroscopy as New Tools Reveal the Secret Life of Molecules

April 14th 2025A leading-edge review led by researchers at Oak Ridge National Laboratory and MIT explores how artificial intelligence is revolutionizing the study of molecular vibrations and phonon dynamics. From infrared and Raman spectroscopy to neutron and X-ray scattering, AI is transforming how scientists interpret vibrational spectra and predict material behaviors.

Real-Time Battery Health Tracking Using Fiber-Optic Sensors

April 9th 2025A new study by researchers from Palo Alto Research Center (PARC, a Xerox Company) and LG Chem Power presents a novel method for real-time battery monitoring using embedded fiber-optic sensors. This approach enhances state-of-charge (SOC) and state-of-health (SOH) estimations, potentially improving the efficiency and lifespan of lithium-ion batteries in electric vehicles (xEVs).

New Study Provides Insights into Chiral Smectic Phases

March 31st 2025Researchers from the Institute of Nuclear Physics Polish Academy of Sciences have unveiled new insights into the molecular arrangement of the 7HH6 compound’s smectic phases using X-ray diffraction (XRD) and infrared (IR) spectroscopy.