Analysis of Ultra-Low Sulfur in Automotive Fuels According to ASTM D2622-10 by Sulfur Analyzer Micro-Z ULS

Application Notebook

The permitted sulfur limit in fuel oils has been decreased to 10 ppm in many regions.

The permitted sulfur limit in fuel oils has been decreased to 10 ppm in many regions. This application note demonstrates that the performance of the Rigaku Micro-Z ULS meets the requirement of ASTM D2622-10, in the analysis of ultra-low sulfur in automotive fuels.

Recent developments in ultra-low sulfur (ULS) fuel have improved fuel efficiency and created cleaner exhaust gas. Globally, the permitted sulfur limit in fuel oils has been decreased to 10 ppm in many countries and regions.

For compliance verification, X-ray fluorescence (XRF) spectrometry is the definitive analysis tool for use at distribution terminals and refineries, as well as mobile or stationary testing laboratories. In recent years, there has been an increasing need for an instrument which does not require the use of helium gas, for instances when acquisition or delivery of helium to the analysis site is difficult.

The Micro-Z ULS (ultra-low sulfur) is a newly developed sulfur analyzer which does not require helium gas in operation. This application note demonstrates that Micro-Z ULS can meet the requirements of ASTM D2622-10.

Experimental Conditions

Instrument

The Micro-Z ULS is a benchtop wavelength dispersive X-ray fluorescence (WDXRF) spectrometer with fixed optics optimized for sulfur analysis. The atmosphere in the optics path of the Micro-Z ULS is a vacuum, so that helium gas is not required. The spectrometer is designed to minimize the restrictions in installation such as the need for cooling water, a special power supply, and installation space. The Micro-Z ULS is equipped with an air-cooled 40 W Cr-target X-ray tube and a doubly curved RX-9 analyzing crystal optimized for low concentration sulfur.

The Micro-Z ULS has a built-in operation panel, which enables simple and easy operation for daily analysis. The counting time was 300 s for peak and background measurements in this experiment.

Sample Preparation

Approximately, 4 mL of each sample was poured into a liquid cell with sample film of 2.5 µm Mylar® film (Chemplex® 100).

Standard and Calibration

"Number 2 diesel fuel" standards and isooctane-based standards provided by VHG Labs, Inc. were used for calibrations of diesel fuel and gasoline respectively.

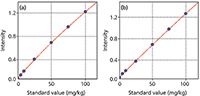

Figure 1: Calibration curve for each material of Micro-Z ULS; (a) diesel fuel, (b) isooctane (for gasoline).

Results

Analysis Results

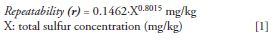

Repeatability tests were carried out using a representative sample for each material. For each sample, two aliquots were prepared and analyzed using the calibration Figure 1; this process was repeated 20 times. The term "r" represents "repeatability" defined by the following formula in ASTM D2622-10 (1):

The difference between successive test results obtained by the same operator with the same apparatus under constant operation conditions on identical test material would exceed the values calculated by equation 1 only in one case in every 20.

The test results, where the maximum value for each fuel is smaller than r, prove that the performance of the Micro-Z ULS meets the requirement of ASTM D2622-10 for diesel fuel and gasoline.

Conclusion

Low concentration sulfur in petroleum-based fuel can be routinely analyzed with high accuracy and precision on the Micro-Z ULS, a benchtop WDXRF spectrometer with fixed optics, which does not require He gas, external water for cooling the X-ray tube, or special power supply. This application note demonstrates that the performance of the Micro-Z ULS meets the requirement of ASTM D2622-10, which has become strict in the recent versions of ASTM D2622.

Reference

(1) ASTM D2622-10(2010), "Standard Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry," ASTM International, p. 12.

Rigaku Corporation

9009 New Trails Drive, The Woodlands TX 77381

tel. (281) 362-2300, fax (281) 364-3628

Website: www.rigaku.com

Thermo Fisher Scientists Highlight the Latest Advances in Process Monitoring with Raman Spectroscopy

April 1st 2025In this exclusive Spectroscopy interview, John Richmond and Tom Dearing of Thermo Fisher Scientific discuss the company’s Raman technology and the latest trends for process monitoring across various applications.

A Seamless Trace Elemental Analysis Prescription for Quality Pharmaceuticals

March 31st 2025Quality assurance and quality control (QA/QC) are essential in pharmaceutical manufacturing to ensure compliance with standards like United States Pharmacopoeia <232> and ICH Q3D, as well as FDA regulations. Reliable and user-friendly testing solutions help QA/QC labs deliver precise trace elemental analyses while meeting throughput demands and data security requirements.