QA/QC of Coatings and Surfaces via Exoscan Handheld FT-IR Analyzer

The application of FT-IR spectroscopy in quality assurance and quality control has largely been limited to laboratory efforts - bringing the samples to the instrument located on a benchtop in a lab. The advent of handheld analyzers such as A2 Technologies' Exoscan system, enables FT-IR to move from the lab to analyses at the sample site.

John Seelenbinder and Alan Rein, A2 Technologies

The application of FT-IR spectroscopy in quality assurance and quality control has largely been limited to laboratory efforts — bringing the samples to the instrument located on a benchtop in a lab. The advent of handheld analyzers such as A2 Technologies' Exoscan system, enables FT-IR to move from the lab to analyses at the sample site. This is particularly relevant when the material to be analyzed cannot be readily sampled or is too large to bring to the lab. Examples of this type of need are often found in QA/QC applications involving large composites and plastic forms or coatings applied to large surfaces.

To address this opportunity, A2 Technologies developed the Exoscan handheld FT-IR. This 6-lb analyzer has been discussed previously (1). Fundamentally, it is an excellent performing FT-IR in a compact package. The system has the performance required to make difficult measurements in a short amount of time while being rugged enough for field use. The interchangeable sample interfaces of the Exoscan allows it to be used for a variety of applications; the interfaces can be easily changed without any alignment required. Additionally, a docking station is available that allows the Exoscan to also function as a benchtop instrument. In this way, the instrument can be used in the lab to develop methods and do routine tests, then moved to the field to conduct measurements on large or complex components which cannot be easily measured by lab techniques. The Exoscan is truly a field instrument that can also function in the lab; this is in contrast to previous FT-IR offerings which were basically lab instruments that were taken, with some difficulty, into the field. The Exoscan is first and foremost a surface analyzer for QA/QC applications involving a wide array of surface types.

The available Exoscan sampling interfaces include:

- diffuse reflection for materials with highly absorbing or scattering surfaces

- specular reflection for coatings on smooth metal surfaces

- grazing angle reflection for ultra thin coatings on metal surfaces

- spherical diamond ATR for powdered or granular materials as well as for identification, confirmation, and analysis of polymers, plastics, and composite forms

- spherical germanium ATR for carbon black filled rubber and for thin coatings on surfaces

The two spherical ATR interfaces have recently been introduced and solve an issue that has made ATR with handheld FT-IR systems less effective than on benchtop systems — sample contact. The ATR technique requires direct, optical contact between the ATR crystal and the sample. Conventional bench instruments use a press to get adequate contact between the sample and a flat crystal. Using hand pressure, sufficient and reproducible contact is nearly impossible to obtain with a flat diamond. Two effects make reproducible contact and uniform pressure easy to achieve with the spherical ATR. First, the spherical shape provides a small contact area, which increases the effective pressure compared to a flat surface when the same amount of force is applied. Secondly, the infrared light is focused over a large area of the spherical surface, allowing interaction when the sample is contacted at many different angles, as shown in Figure 1.

Figure 1: Schematic representation of the Exoscan Spherical ATR sample interface showing multiple sample angles which result in good contact between the sample and the ATR crystal.

Two different crystal materials are available as spherical ATR sample interfaces for the Exoscan: diamond and germanium. The durability and chemical resistivity of the spherical diamond ATR makes it the most widely applicable sample interface for measurement of a wide variety of coated surfaces such as paints and primers on substrates, as well as for general identification and confirmation of plastics. The analytical pathlength (depth of penetration) of an ATR sample interface is determined by a number of factors including the refractive index of the ATR crystal. The high refractive index of germanium creates a very short path length. This is extremely useful for measurement of highly absorbing samples, such as carbon filled polymers, as well as measurements where high surface selectivity is required.

A primary application of the Exoscan with the spherical diamond ATR interface is the identification and qualification of paints and coatings. Two spectra typical of paint measurement are shown in Figure 2. Both of the spectra were collected at 4 cm-1 resolution in about 10 s. The top spectrum is a measurement of a polyurethane topcoat while the bottom spectrum is a measurement of an epoxy paint.

Figure 2: Examples of a polyurethane paint (top) and an epoxy paint (bottom) measured with the hand-held Exoscan using the spherical diamond ATR sample interface. The spectra, which were measured at 4 cm-1 resolution, took approximately 10 s to acquire.

As discussed above, the Exoscan with a spherical germanium ATR interface is useful for measuring both highly absorbing materials and also surface selective analyses. An Exoscan with the germanium spherical ATR was used to measure a library of o-ring materials. Use of the correct o-ring is critical in many applications; however, supplier and user errors account for many mistakes each year. Carbon filled rubbers are often difficult to measure by infrared because the nonspecific carbon absorbance causes a large baseline shift. This baseline shift can be minimized by measurement with a germanium ATR. Figure 3 shows an example of a library match made between an o-ring measured with the spherical germanium ATR on the Exoscan compared to an o-ring library. Even though the sample is heavily loaded with carbon black, it is easily identified.

Figure 3: A library search result showing a match to a hydrocarbon based o-ring measured with the Exoscan using the spherical germanium ATR sample interface. Even though it contains a large amount of carbon filling, spectral features are readily evident.

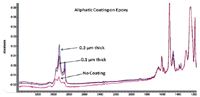

The spherical germanium ATR also provides highly surface selective analysis. The Exoscan has been used to measure a thin aliphatic coating on an epoxy surface. The aliphatic coating was applied as a processing aid; the thickness was less than 0.5 µm. The Exoscan was used to spot check the surface in order to find areas of unsatisfactory application and to determine if the aliphatic coating was applied evenly to the surface. Figure 4 shows spectra of the uncoated epoxy substrate, the substrate with a thin (0.1 µm) coating and the correct (0.3 µm) coating. The epoxy signature is strong in these samples; however, the surface selective nature of the germanium ATR allows quantitative analysis of the ultra thin surface coating.

Figure 4: Spectra measured of aliphatic coatings on an epoxy substrate. Examples of an uncoated substrate, a thin (0.1 µm) coating and a thick (0.3 µm) coating measured with the hand-held Exoscan using the spherical germanium ATR sample interface. Each spectrum was collected in approximately 10 s.

Because of the optimization of sampling interface design, coupled with the fundamental performance of the Exoscan, it is often sufficient to only scan for 3–4 s to get excellent spectra and identification of materials, and a wide variety of material and surfaces can be analyzed with this capability (Figures 2, 3, and 4).

Conclusion

Exoscan is an example of a superior performing, rugged, FT-IR analyzer that can be used on the benchtop or handheld at-site for a range of industrial QA/QC needs. Equally important are sampling interfaces that not only provide the versatility for analyzing the broad range of materials and surfaces that QA/QC applications require, but also designed to be effective when used in handheld mode. The coupling of performance, reliability, ease-of-use, and versatile sampling enables QA/QC FT-IR analyzers to move beyond the lab and directly to where materials and objects need to be measured.

References

(1) A. Rein and F. Higgins, "Hand-Held FTIR Analyzers — A New Capability for At-Site Measurements of Rock and Minerals — Use of FTIR for Elucidating Rock and Mineral Composition," Spectroscopy, The Application Notebook. 25(9), 16–17 (2010).

A2 Technologies

14 Commerce Drive, Danbury, CT 06810

tel. (203) 312-1100, fax (203) 312-1058

Website: www.a2technologies.com

AI Shakes Up Spectroscopy as New Tools Reveal the Secret Life of Molecules

April 14th 2025A leading-edge review led by researchers at Oak Ridge National Laboratory and MIT explores how artificial intelligence is revolutionizing the study of molecular vibrations and phonon dynamics. From infrared and Raman spectroscopy to neutron and X-ray scattering, AI is transforming how scientists interpret vibrational spectra and predict material behaviors.

Real-Time Battery Health Tracking Using Fiber-Optic Sensors

April 9th 2025A new study by researchers from Palo Alto Research Center (PARC, a Xerox Company) and LG Chem Power presents a novel method for real-time battery monitoring using embedded fiber-optic sensors. This approach enhances state-of-charge (SOC) and state-of-health (SOH) estimations, potentially improving the efficiency and lifespan of lithium-ion batteries in electric vehicles (xEVs).

New Study Provides Insights into Chiral Smectic Phases

March 31st 2025Researchers from the Institute of Nuclear Physics Polish Academy of Sciences have unveiled new insights into the molecular arrangement of the 7HH6 compound’s smectic phases using X-ray diffraction (XRD) and infrared (IR) spectroscopy.