Advantages of Silicon Drift Detectors

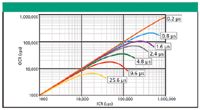

The availability of new silicon drift detectors (SDD) allows for more precise measurements in less acquisition time. SDDs are often praised for their excellent energy resolution, but it is their increased throughput that make them ideal for many industrial applications. Due to the detector's smaller capacitance, a much shorter peaking time is used in the shaping amplifier without sacrificing resolution. This dramatically increases the throughput of the system. Compared with a conventional Si-PIN detector where the peaking time is as long as 25 ms, the drift detector operates at 1.6 ms, thereby increasing throughput from 10,000 counts per second to over 100,000. This advantage can be used in two primary ways.

The availability of new silicon drift detectors (SDD) allows for more precise measurements in less acquisition time. SDDs are often praised for their excellent energy resolution, but it is their increased throughput that make them ideal for many industrial applications. Due to the detector's smaller capacitance, a much shorter peaking time is used in the shaping amplifier without sacrificing resolution. This dramatically increases the throughput of the system. Compared with a conventional Si-PIN detector where the peaking time is as long as 25 ms, the drift detector operates at 1.6 ms, thereby increasing throughput from 10,000 counts per second to over 100,000. This advantage can be used in two primary ways.

Figure 1: Throughput with the silicon drift detector.

First, the same acquisition time can be used as with the conventional detector. Since a faster peaking time is used, the flux of the x-ray tube can be increased without affecting the dead time of the system. In the same acquisition interval many more counts are accumulated. The final result will be a more precise, statistically relevant spectrum. Trace elements and elements hidden in the background can now also be identified.

Second, if more rapid measurements are necessary but not increased precision or trace analysis, the acquisition time can be made much shorter. The shorter peaking time again allows for an increase in x-ray tube flux and therefore good statistics in the spectrum despite the shorter accumulation time. This makes this detector ideal for online processing applications where measurement intervals can be sub second. It is also useful in situations where the sample number is high. Now many more analysis can be conducted in the same work time.

Figure 2: Amptek X-123SDD.

The detector is housed inside the same TO-8 package as Amptek's other detectors, so its form-factor is a direct replacement for current systems. The X-123SDD configuration contains the complete spectrometer: detector, preamplifier, digital processor, and power supplies. The X-123 connects via USB or RS232 and only needs a +5VDC power input (AC adapter included). The X-123SDD is ideal for high speed OEM applications with fast entry to the market.

Amptek, Inc.

14 Deangelo Drive

Bedford, MA 01730

Tel. (781) 275-2242, Fax (781) 275-3470

Thermo Fisher Scientists Highlight the Latest Advances in Process Monitoring with Raman Spectroscopy

April 1st 2025In this exclusive Spectroscopy interview, John Richmond and Tom Dearing of Thermo Fisher Scientific discuss the company’s Raman technology and the latest trends for process monitoring across various applications.

A Seamless Trace Elemental Analysis Prescription for Quality Pharmaceuticals

March 31st 2025Quality assurance and quality control (QA/QC) are essential in pharmaceutical manufacturing to ensure compliance with standards like United States Pharmacopoeia <232> and ICH Q3D, as well as FDA regulations. Reliable and user-friendly testing solutions help QA/QC labs deliver precise trace elemental analyses while meeting throughput demands and data security requirements.