Optimized Long-Term Stability for Enhanced Laboratory Productivity with ICP

The factors that affect the long-term stability of ICP instruments are discussed and details of the performance of the Thermo Scientific iCAP 6000 Series for extended period analyses are given.

The factors that affect the long-term stability of ICP instruments are discussed and details of the performance of the Thermo Scientific iCAP 6000 Series for extended period analyses are given.

The long-term stability of ICP instruments is pivotal to the accuracy and the precision of the results produced during extended runs in high-throughput laboratories, such as those performing environmental analysis. Re-calibration and the re-analysis of samples arising from instrument drift adds significant unwanted cost.

Some key factors affecting the long-term stability of an ICP instrument include the following:

- Consistency of sample uptake rate

- Consistency of gas flow rates

- Consistency of plasma power

- Thermal regulation and isolation of the optical components and detector from the plasma source

The use of peristaltic pumps for sample uptake is standard and uptake rate variations can be corrected with the use of internal standardization. Mass-flow controllers represent the optimum gas flow control method due to their ability to negate pressure and temperature variation effects. Plasma power is delivered by radio frequency (RF) plasma generators, the ideal design of which is solid-state for low maintenance, with the swing-frequency method of impedance-matching for instantaneous compensation upon sample matrix change. The thermal regulation of optical components within the system is essential in order to eradicate the mechanical expansion/contraction of critical components. Intelligent instrument design can significantly improve long-term stability by isolating temperature differentials and regulating the thermal environment of critical components. In the Thermo Scientific iCAP 6000 Series, a thermal break between the torch box and fore-optics is maintained by drawing air from the extraction through the base casting. The optical tank is maintained at a thermostatically controlled temperature, as is the Peltier-cooled detector.

Experimental Conditions

A 1 ppm multi-element solution was continuously aspirated into an iCAP 6500 Duo after a single calibration. The standard sample introduction system was used. The following parameters were used: Pump 50 rpm, Nebulizer gas flow 0.65 L/min, Auxiliary gas flow 0.5 L/min and RF power 1150 W.

Results

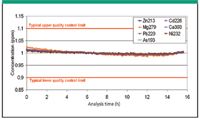

Figure 1 shows the stability of a range of elements at 1 ppm over a 16-h period after a single calibration, with no updates.

Figure 1: 16-hour stability after a single calibration without updates.

Typical quality control levels are ± 10%. The graph in Figure 1 shows the excellent stability during this extended period with results well within control levels, being exceptionally stable at less than 3% relative drift over the course of the run. This would enable extended runs as only a single calibration was required to maintain accuracy during the analyses.

Conclusions

The Thermo Scientific iCAP 6500 ICP, with its fully mass-flow controlled gas system, swing-frequency RF generator, EMT torch, thermal-break torch box design, and temperature regulated optical system is ideally suited to high throughput environmental analyses where stability is essential to ensure excellent precision and accuracy during extended runs. The stability rated at not exceeding 0.5 % relative drift in signal intensity per hour ensures the highest efficiency as fewer calibrations are needed during the analyses, and with such excellent precision and accuracy, the event of recalibration and re-analyses due to QC failures is significantly diminished.

Thermo Scientific (part of Thermo Fisher Scientific)

5225 Verona Road, Madison, WI 53711

Tel. +1-800-532-4752

Email: analyze@thermo.com

Website: www.thermo.com/icp-enviro

Thermo Fisher Scientists Highlight the Latest Advances in Process Monitoring with Raman Spectroscopy

April 1st 2025In this exclusive Spectroscopy interview, John Richmond and Tom Dearing of Thermo Fisher Scientific discuss the company’s Raman technology and the latest trends for process monitoring across various applications.

A Seamless Trace Elemental Analysis Prescription for Quality Pharmaceuticals

March 31st 2025Quality assurance and quality control (QA/QC) are essential in pharmaceutical manufacturing to ensure compliance with standards like United States Pharmacopoeia <232> and ICH Q3D, as well as FDA regulations. Reliable and user-friendly testing solutions help QA/QC labs deliver precise trace elemental analyses while meeting throughput demands and data security requirements.