Ultrafast and Automated Confocal Raman Imaging on Large Samples

In the Life Sciences, Materials Research, and Nanotechnology, obtaining as much information as possible about the chemical and structural composition of a sample is essential. Confocal Raman Microscopy can play an important role in the nondestructive characterization and imaging of chemical properties while requiring only minimal, if any sample preparation. Systematic and routine research tasks with repetitive experiments or a large number of measurement points, as well as high-level quality control can benefit from an automated instrument.

In the Life Sciences, Materials Research, and Nanotechnology, obtaining as much information as possible about the chemical and structural composition of a sample is essential. Confocal Raman Microscopy can play an important role in the nondestructive characterization and imaging of chemical properties while requiring only minimal, if any sample preparation. Systematic and routine research tasks with repetitive experiments or a large number of measurement points, as well as high-level quality control can benefit from an automated instrument.

Figure 1

The automated WITec alpha500 imaging system incorporates an automated sample stage, which provides the ability to acquire data (spectra, Raman images, Raman depth-profile images) from an arbitrary, user-defined number of measurement points without any online process control by an operator. The design of the automated stage makes large samples accessible for Raman measurements while also allowing multi-point measurements or large area scans to be performed. The operator simply predefines the measurement routine which is to be executed on the sample automatically by the instrument. Assuming, for example, 50 sample positions are to be measured with a manual system, an operator must move the microscope stage to each of the 50 positions individually in order to execute the measurement procedure. When operating the automated alpha500 system, the 50 positions can be predefined and then measured automatically, with no operator presence required.

For applications requiring Raman spectra to be acquired very rapidly or using a low laser excitation power, the most sensitive "Ultrafast Raman Imaging Mode" can be used. It allows a Raman spectrum to be acquired in 760 microseconds. The resulting Raman images, consisting of tens of thousands of spectra can be analyzed with a resolution down to 200 nm. An emulsion was investigated to exemplify the capabilities of this technique. Emulsions play an important role in various production processes e.g. in the food and pharmaceutical industries. Figure 1a shows a color-coded Raman image of an oil-alkane-water mixture used as an example of an emulsion (Green: oil; Red: alkane; Blue: water). The scan range was 60 × 60 μm and 200 × 200 pixels, resulting in a total of 40,000 spectra. The acquisition time was 760 microseconds per spectrum and 42 seconds per image. Figure 1b shows the corresponding Raman spectra.

Figure 1b

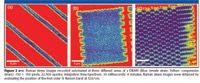

A second example describes the automated analysis of a DRAM chip. A series of Raman measurements were performed on three different areas on the chip. Raman images were acquired by recording a complete Raman spectrum at every image pixel, producing a 2D array of 150 × 150 Raman spectra. The integration time for each individual Raman spectrum was 10 ms, thus the array of 22,500 Raman spectra was acquired in less than 4 min per image. By evaluating the position of the first order Si Raman band at 520/cm, stress images of the selected areas can be obtained. Figure 2 a–c shows the stress images taken from the three pre-selected areas.

Figure 2 aâc

Conclusion

Knowledge of chemical components and their distribution in a sample is of immense importance for R&D as well as quality control in various fields of research and industry. It was demonstrated that Confocal Raman Imaging provides the ability to non-invasively image the chemical properties of samples with the highest resolution. An automated system allows the automated execution of predefined measurement sequences on an arbitrary, user-defined number of sample positions for the most comprehensive, nondestructive and rapid sample analysis available without any online process control by an operator.

WITec GmbH

Hoervelsinger Weg 6

89081 Germany

Phone: +49(0)731 140 700

Fax: +49(0)731 140 7020

E-mail: harald.fischer@witec.de

Thermo Fisher Scientists Highlight the Latest Advances in Process Monitoring with Raman Spectroscopy

April 1st 2025In this exclusive Spectroscopy interview, John Richmond and Tom Dearing of Thermo Fisher Scientific discuss the company’s Raman technology and the latest trends for process monitoring across various applications.

A Seamless Trace Elemental Analysis Prescription for Quality Pharmaceuticals

March 31st 2025Quality assurance and quality control (QA/QC) are essential in pharmaceutical manufacturing to ensure compliance with standards like United States Pharmacopoeia <232> and ICH Q3D, as well as FDA regulations. Reliable and user-friendly testing solutions help QA/QC labs deliver precise trace elemental analyses while meeting throughput demands and data security requirements.